E Vitamin

E Vitamin Related Searches

Mobile Gps Units Gps City Backcountry Navigator Pro Gps Garman Gps Gps Forum E VitaminHot Searches

E Vitamin Supplier & Manufacturer from China

Okorder.com is a professional E Vitamin supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest E Vitamin firm in China.Hot Products

FAQ

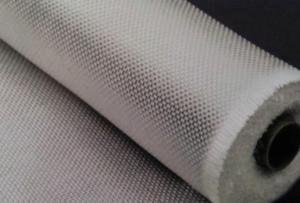

- Yes, fiberglass fabrics are generally easy to sew or work with. They have a smooth texture and do not fray easily, making them manageable for sewing projects. Additionally, their lightweight nature allows for flexibility and ease of handling. However, it is important to take necessary precautions such as wearing protective gear and ensuring proper ventilation when working with fiberglass fabrics due to their potential health hazards.

- Fiberglass fabric finishes designed to enhance abrasion resistance come in various types. These finishes are applied during the fabric's manufacturing process, boosting its durability and resistance to wear and tear. One commonly utilized finish for abrasion resistance is the silicone coating. By forming a protective layer on the fabric's surface, this coating increases resistance to abrasion, ensuring a longer lifespan. Silicone-coated fiberglass fabrics find frequent use in applications that involve high levels of abrasion, like conveyor belts and industrial curtains. Another popular choice for abrasion resistance is the PVC coating. This type of coating acts as a strong barrier against friction and wear, making the fabric more resistant to tearing, puncturing, and other forms of damage. PVC-coated fiberglass fabrics are commonly seen in protective clothing, tents, and machinery or equipment covers. Apart from silicone and PVC coatings, there are other finishes available to enhance abrasion resistance in fiberglass fabrics. For instance, some fabrics may undergo treatment with a polyurethane coating, which offers similar benefits to silicone and PVC coatings. Other finishes may involve chemical treatments or laminations that provide improved abrasion resistance. Ultimately, the selection of a fiberglass fabric finish for abrasion resistance depends on the specific application and desired level of protection. Manufacturers and users of fiberglass fabrics should carefully consider the intended use and potential wear and tear the fabric may endure to choose the most suitable finish for their requirements.

- Typically, fiberglass fabric is not employed in the creation of tablecloths. Such a fabric is renowned for its durability, strength, and resistance to heat, rendering it more appropriate for usage in insulation, construction materials, or protective clothing. Conversely, tablecloths are usually fashioned from fabrics that possess qualities like softness, lightweightness, and ease of cleaning, such as cotton, linen, polyester, or blends thereof. These fabrics provide a pleasant and visually pleasing surface for dining and are better suited for the purpose of tablecloths.

- Fiberglass fabric generally exhibits excellent chemical resistance properties. The material is known for its resistance to a wide range of chemicals, including acids, alkalis, solvents, and most organic compounds. This is mainly due to the fact that fiberglass is composed of glass fibers, which are inherently non-reactive and do not readily degrade or dissolve when exposed to various chemicals. The chemical resistance of fiberglass fabric can be further enhanced by the addition of specific coatings or treatments. For instance, a silicone coating can provide additional protection against certain chemicals and improve overall resistance. Additionally, some manufacturers offer specialty fiberglass fabrics that are specifically designed to resist particular chemicals or environments, such as high-temperature or corrosive conditions. However, it is important to note that while fiberglass fabric is generally chemically resistant, its performance can vary depending on the specific chemical involved and the duration and intensity of exposure. Some particularly aggressive chemicals or prolonged exposure to certain substances may eventually cause degradation or damage to the fabric. Therefore, it is always advisable to consult the manufacturer's guidelines or conduct specific chemical compatibility tests to ensure optimal performance in a given chemical environment.

- Yes, fiberglass fabric can be used for ducting. Fiberglass is a lightweight and flexible material that has excellent insulation properties. It is often used in the construction of air ducts to help maintain the temperature and airflow of the system. Fiberglass fabric can be wrapped around the ducts or used as lining to provide thermal insulation and prevent heat transfer. Additionally, fiberglass is resistant to moisture, mold, and mildew, making it a suitable choice for ducting in humid environments. However, it is important to note that fiberglass fabric should be properly installed and sealed to ensure proper air quality and prevent any loose fibers from entering the duct system.

- Yes, fiberglass fabric can be used for reinforcing plaster or stucco. Fiberglass fabric is a strong and durable material that can provide additional strength and stability to plaster or stucco surfaces. It is commonly used as a reinforcement material in construction projects to prevent cracks and increase the overall durability of the plaster or stucco. The fiberglass fabric is typically applied to the surface before the plaster or stucco is applied, and it helps to distribute stress evenly, reducing the chances of cracking or crumbling. Additionally, fiberglass fabric is resistant to moisture and weathering, making it a suitable choice for exterior applications where plaster or stucco may be exposed to harsh environmental conditions. Overall, using fiberglass fabric for reinforcing plaster or stucco can enhance the structural integrity and longevity of the finished surfaces.

- Cutting and sewing fiberglass fabric is a comparatively easy task. You can cut it with either standard fabric scissors or a sharp utility knife. Nonetheless, it is important to acknowledge that fiberglass fabric may pose more challenges in the cutting process due to its strength and durability. To ensure clean cuts, it is advisable to utilize sharp tools and apply steady pressure. Regarding sewing, fiberglass fabric can be stitched using a regular sewing machine or by hand. It is recommended to employ a heavy-duty needle and a robust thread like polyester or nylon. Furthermore, using a walking foot attachment on the sewing machine can be beneficial in managing the fabric's thickness and stiffness. In general, even though fiberglass fabric may require a bit more effort and specialized tools compared to traditional fabrics, it is still possible to cut and sew it with relative ease. By employing the appropriate tools, techniques, and precautions, you can effectively work with fiberglass fabric for various projects.

- Fiberglass fabric performs well in high-temperature environments due to its excellent heat resistance properties. It can withstand temperatures up to 1000°F (540°C) without significantly degrading or melting. This makes it a suitable material for various applications such as insulation, fireproofing, and protective clothing in industries where high temperatures are present.