Aisi 1020 Hot Rolled

Aisi 1020 Hot Rolled Related Searches

Hot Water Bags For Pain Relief Micro Inverter For Solar Panel Stainless Steel Bucket With Lid Hot Water Bottle With Hose Solar Panel With Ac Inverter Solar Panel With Inverter Kit Solar Panel Kits With Inverter Inverter With Solar Panel Aluminum Sheet With Holes Cover Ham With Aluminum FoilHot Searches

Steel Mesh Panels For Sale Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Price Of Shipping Containers For Sale Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For Sale Aluminum Coil Stock For Sale Large Led Screens For Sale Aluminum Gutter Coil For Sale Used Aluminum Scaffolding For Sale 1/4 Aluminum Plate For SaleAisi 1020 Hot Rolled Supplier & Manufacturer from China

Okorder.com is a professional Aisi 1020 Hot Rolled supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Aisi 1020 Hot Rolled firm in China.Hot Products

FAQ

- Yes, steel sheets can be used for fencing. They offer durability, strength, and security, making them an excellent choice for fencing applications.

- To create a composite material that surpasses the strength and durability of conventional steel, the lamination of steel sheets encompasses various sequential steps. Initially, the steel sheets undergo a thorough cleaning and preparation process to eliminate any impurities or contaminants. This step is vital in guaranteeing a robust bond between the layers and preventing any flaws in the end product. Subsequently, an adhesive layer is administered onto one or both sides of the steel sheets. The selection of the adhesive is contingent upon the desired characteristics of the laminated steel, with options ranging from thermosetting resins to thermoplastic materials. Once the adhesive is applied, the steel sheets are assembled, with the adhesive layer(s) sandwiched in between. To initiate the bonding process, the sheets are subjected to intense heat and pressure. This can be achieved through the utilization of a hydraulic press or a hot rolling mill. The combined effect of heat and pressure causes the adhesive to liquefy and flow, forming a sturdy chemical bond between the steel sheets. The application of high pressure ensures the even distribution of the adhesive and fills any gaps or irregularities that may exist between the sheets. Upon the completion of the bonding process, the laminated steel sheets are cooled and trimmed to the desired size and shape. They can then undergo further processing, such as cutting, bending, or welding, to fulfill specific application requirements. In summary, the process of laminating steel sheets encompasses a series of actions, including cleaning and prepping the sheets, adhesive application, sheet stacking, exposure to high temperature and pressure, cooling, and finalizing the shape. This process results in a composite material boasting enhanced strength, corrosion resistance, and other desirable properties when compared to traditional steel.

- Certainly! Conveyor belts can indeed utilize steel sheets. Steel, known for its versatility and durability, is capable of withstanding substantial weights and elevated temperatures, rendering it suitable for the purpose of conveyor belts. By manipulating steel sheets into different forms and dimensions, customization can be achieved to meet the precise demands of individual conveyor systems. Furthermore, steel sheets possess exceptional resistance against wear, impacts, and corrosion, guaranteeing an extended lifespan for the conveyor belt. All in all, steel sheets offer a dependable and sturdy solution for conveyor belt applications across industries such as manufacturing, mining, and logistics.

- Yes, steel sheets can be used for storage shelves. Steel is a durable and strong material that can provide sufficient support and stability for storing items on shelves.

- Yes, steel sheets are suitable for marine environments due to their high strength and corrosion resistance properties. They can withstand harsh conditions such as saltwater exposure and are commonly used in the construction of ships, offshore platforms, and other marine structures.

- Steel sheets are known for their high durability and strength, making them suitable for various applications. When it comes to extreme temperatures, steel sheets generally have a high melting point and can withstand high temperatures without losing their structural integrity. However, it is important to note that the exact temperature limit depends on the specific type and grade of steel being used. For example, stainless steel sheets have a higher resistance to heat compared to carbon steel sheets. Additionally, factors such as the duration of exposure to extreme temperatures and the presence of other environmental factors may also influence the steel sheets' performance. Therefore, it is crucial to consider these factors and consult with experts or refer to specific product specifications to determine if a particular steel sheet is suitable for a specific extreme temperature application.

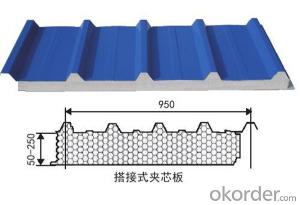

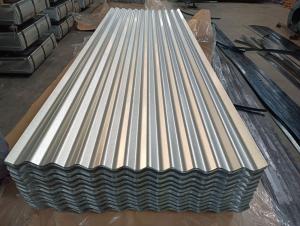

- There exists a variety of steel sheet grades, each possessing its own distinctive properties and applications. Among the commonly utilized grades are: 1. Carbon Steel: This grade of steel sheet is the most prevalent and extensively employed. It comprises varying carbon levels and is renowned for its robustness and durability. Carbon steel sheets find utility across diverse sectors, including construction, automotive, and manufacturing. 2. Stainless Steel: Distinguished by its elevated chromium content, this steel sheet grade showcases outstanding resistance to corrosion. Industries such as food processing, chemical, and medical frequently employ stainless steel sheets where corrosion resistance plays a pivotal role. 3. Galvanized Steel: To shield against corrosion, this type of steel sheet is coated with a layer of zinc. Galvanized steel sheets often serve in outdoor settings, such as roofing, fences, and gutters, where exposure to moisture and the elements is commonplace. 4. Alloy Steel: By incorporating additional elements like manganese, nickel, or chromium, this grade of steel sheet enhances its mechanical properties. Alloy steel sheets are extensively used in applications demanding heightened strength, such as construction equipment, aircraft components, and machinery. 5. Tool Steel: Designed with elevated hardness and wear resistance, this grade of steel sheet is ideal for tools and dies. Industries such as automotive, aerospace, and manufacturing frequently employ tool steel sheets. It's crucial to note that these represent only a fraction of the available steel sheet grades, as numerous specialized grades are tailored to specific applications. The choice of grade depends on factors such as desired strength, corrosion resistance, and specific application requirements.