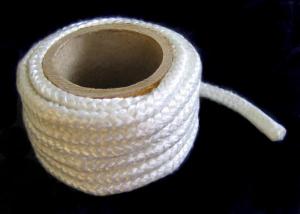

Textured Fiberglass Round Braided

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5t kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General info of Textured Fiberglass Round Braided

1. Fire fiberglass rope is made of continuous filament texturized C or E glass yarns and is extremely strong, resilient, and flexible.

2. Fire fiberglass rope are asbestos free, cause no harm to health, making them ideal replacements to asbestos ones.

3. For higher loads, the round braided and square braided ropes can be reinforced by steel wires.

4. Fire fiberglass rope also can be coated with graphite or vermiculite to increase thermal insulation and abrasive resistance.

Fire Fiberglass Rope Application:

1. Fire fiberglass rope are widely used as gasket for industrial ovens and furnaces, boilers and wood burning stoves.

Specifications of Textured Fiberglass Round Braided

1. Fire Fiberglass Rope 2. Round braided or square braided 3. Temperature: 450C-550C 4. Thickness:3mm-100mm

- Q:How does glass fiber textile perform in terms of moisture resistance?

- Glass fiber textile is known for its excellent moisture resistance properties. The composition of glass fibers, which are made from molten glass, provides inherent resistance against moisture absorption. This means that glass fiber textiles do not absorb water easily, making them highly resistant to moisture. Due to their hydrophobic nature, glass fiber textiles are not affected by water or high humidity levels. They do not retain moisture, preventing the growth of mold, mildew, or rot. This makes them suitable for applications where moisture resistance is crucial, such as in outdoor fabrics, insulation materials, and protective clothing. Additionally, glass fiber textiles have a low thermal conductivity, which means they do not transfer heat or cold easily. This property further helps in maintaining their moisture resistance as they are less prone to condensation, which can lead to dampness and moisture-related issues. Overall, glass fiber textiles perform exceptionally well in terms of moisture resistance. Their inherent hydrophobic nature and low thermal conductivity make them a reliable choice for various applications where moisture management is essential.

- Q:Can glass fiber textiles be used for reinforcement in plastic bottles?

- Yes, glass fiber textiles can indeed be used for reinforcement in plastic bottles. Glass fiber textiles, also known as fiberglass, are lightweight, strong, and durable materials that are commonly used in various industries, including automotive, aerospace, and construction. When incorporated into plastic bottles, glass fiber textiles can enhance their structural integrity and reduce the risk of deformation or breakage. The glass fibers add strength and stiffness to the plastic matrix, making the bottles more resistant to impact, pressure, and temperature changes. Additionally, glass fiber reinforcement can help to reduce the amount of plastic required in the bottle's construction, making it a more sustainable option. However, it is important to note that the addition of glass fibers may affect the transparency of the plastic bottle, as the fibers can cause a slight opacity. Therefore, if transparency is a crucial factor, alternative reinforcement materials such as carbon fiber or aramid fibers may be preferred.

- Q:Can glass fiber textiles be used in fashion?

- Yes, glass fiber textiles can be used in fashion. Glass fiber is a versatile material that can be woven into various textile forms, offering unique properties such as strength, durability, and flame resistance. It can be used to create innovative and futuristic designs in fashion, providing a modern and unconventional aesthetic. However, due to its stiffness and potential for discomfort, glass fiber textiles are more commonly used in specialized fashion applications like performance wear, avant-garde fashion, or as accents and embellishments rather than for everyday clothing.

- Q:Can glass fiber textiles be used as insulation material?

- Yes, glass fiber textiles can be used as insulation material. Glass fiber textiles, also known as fiberglass, are commonly used in insulation applications due to their excellent thermal and acoustic insulation properties. They are made by weaving or knitting fine strands of glass into a fabric-like material. Glass fiber textiles have low thermal conductivity, meaning they can effectively prevent heat transfer between two surfaces. This makes them ideal for insulating buildings, pipes, and other structures. They are also resistant to fire, which adds an additional layer of safety to the insulation. Furthermore, glass fiber textiles are lightweight, flexible, and easy to install. They can be easily cut and shaped to fit any space or object, making them versatile for various insulation needs. They are also durable and long-lasting, with a high resistance to moisture, chemicals, and pests. Overall, glass fiber textiles are a popular choice for insulation due to their thermal performance, fire resistance, versatility, and durability.

- Q:What are the advantages of using glass fiber textiles over other materials?

- There are several advantages to using glass fiber textiles over other materials. Firstly, glass fiber textiles are known for their exceptional strength and durability. The inherent properties of glass fibers, such as high tensile strength and resistance to breaking or stretching, make them suitable for a wide range of applications. This strength allows glass fiber textiles to withstand heavy loads and harsh environments, making them highly reliable and long-lasting. Secondly, glass fiber textiles offer excellent heat resistance. Unlike many other materials, glass fibers can withstand high temperatures without losing their structural integrity. This property makes them suitable for applications where heat insulation or fire resistance is required, such as in the construction of fireproof clothing, insulation materials, or protective gear. Another advantage of glass fiber textiles is their excellent chemical resistance. Glass fibers are non-reactive to most chemicals, acids, and alkalis. This makes them ideal for use in industries where exposure to corrosive substances is common, such as the chemical or petrochemical industry. Additionally, their resistance to moisture and mold growth makes them a suitable choice for applications in damp or humid environments. Furthermore, glass fiber textiles are lightweight and have a high strength-to-weight ratio. This characteristic makes them an attractive choice for applications where weight reduction is essential, such as in aerospace or automotive industries. The lightweight nature of glass fiber textiles also allows for easy handling and installation, reducing labor costs and improving efficiency. Lastly, glass fiber textiles are highly versatile and can be easily customized to meet specific requirements. They can be woven, knitted, or braided into various forms, allowing for flexibility in design and application. Glass fiber textiles can also be coated or combined with other materials to enhance specific properties, such as adding abrasion resistance or improving electrical conductivity. In conclusion, the advantages of using glass fiber textiles over other materials include exceptional strength and durability, excellent heat and chemical resistance, lightweight nature, and versatility. These properties make glass fiber textiles a preferred choice in a wide range of industries, from construction and automotive to aerospace and chemical manufacturing.

- Q:How do glass fiber textiles resist tearing?

- Glass fiber textiles resist tearing due to their inherent strength and durability. The fibers used in these textiles are strong and have high tensile strength, allowing them to withstand external forces without easily breaking or tearing. Additionally, the tight weaving or knitting of the fibers creates a dense and closely interlocked structure, further enhancing their tear resistance. This combination of strong fibers and tight construction makes glass fiber textiles highly resistant to tearing.

- Q:What is the tensile strength of glass fiber textiles?

- The tensile strength of glass fiber textiles can vary due to various factors, including the manufacturing process, type of glass, and specific application. However, glass fiber textiles are generally recognized for their superior tensile strength when compared to other textile materials. On average, glass fiber textiles exhibit a tensile strength ranging from 2000 to 5000 megapascals (MPa), which far surpasses materials like cotton or polyester. This exceptional strength renders glass fiber textiles suitable for applications that demand durability and robustness, such as reinforcement in the construction industry or in the production of composite materials. It should be noted that fabric construction, fiber orientation, and any additional coatings or treatments applied to the textiles can also influence the tensile strength.

- Q:Are glass fiber textiles resistant to pilling?

- In general, glass fiber textiles do not tend to pill. Pilling happens when loose fibers on the fabric's surface get tangled and create small balls or clusters. However, glass fiber textiles possess a smooth and strong surface that prevents the formation of pills. This is due to the fact that glass fibers are inorganic and do not have the same inclination to fray or break as natural or synthetic fibers. Moreover, glass fibers are often tightly woven, further decreasing the likelihood of pilling. Overall, glass fiber textiles are renowned for their exceptional resistance to pilling, which makes them a popular choice for applications where durability and longevity are crucial factors.

- Q:Can glass fiber textile be used in window treatments?

- Yes, glass fiber textile can be used in window treatments. It is a versatile material that offers durability, resistance to heat and UV rays, and is often used for creating blinds, curtains, and shades for windows.

- Q:How do glass fiber textiles perform in terms of durability?

- Glass fiber textiles possess remarkable durability, renowned for their exceptional longevity. Utilizing glass fibers in the production of textiles yields fabrics that boast immense strength and resilience against damage. These textiles exhibit the ability to endure elevated levels of stress, with a decreased likelihood of stretching or shrinking when compared to alternative textile options. Moreover, glass fiber textiles exhibit outstanding resistance to chemicals, moisture, and UV radiation, rendering them ideal for outdoor use and in environments with challenging conditions. Furthermore, the enduring nature of glass fiber textiles guarantees their structural integrity over time, granting them remarkable durability across a variety of applications, including the automotive, aerospace, and construction industries.

1. Manufacturer Overview |

|

|---|---|

| Location | Beijing, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 3 Million |

| Main Markets | North America;Southeast Asia ;Western Europe ;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjing |

| Export Percentage | 60% - 70% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | |

| Product Price Range | High; Average |

Send your message to us

Textured Fiberglass Round Braided

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5t kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords