Geotextile Woven PP Earthwork for Road and Railway

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

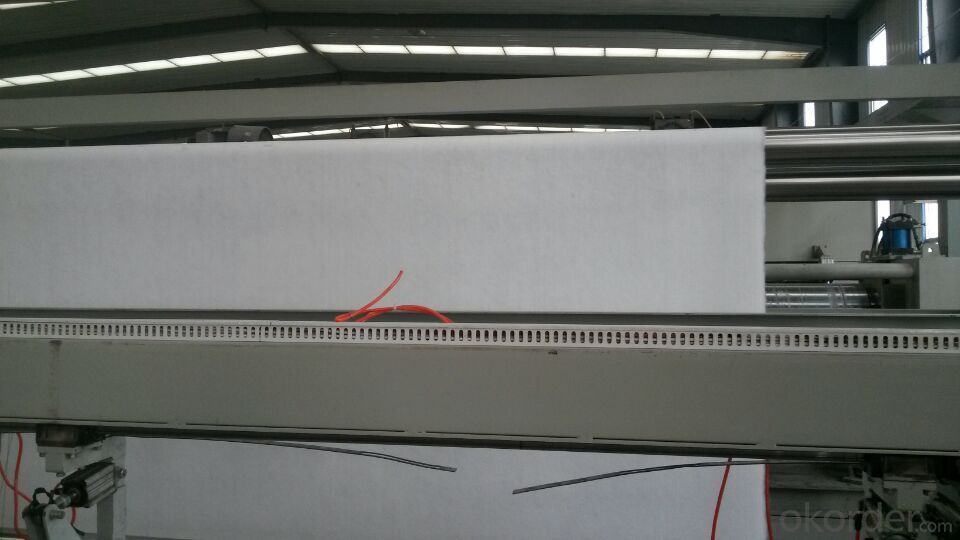

Type: | Geotextiles | Place of Origin: | Shan Dong , China (Mainland) | Brand Name: | CMAX woven geotextile |

Model Number: | High Strength | Geotextile Type: | Woven Geotextiles | Color: | White |

Strength: | 200/50KN/M | Elongation: | <15% | Width: | 3.6m |

Roll length: | 200m |

Packaging & Delivery

Packaging Details: | Woven geotextile package:Rolled with cardboard core, wrapped with PE film and PP tape fabric |

Delivery Detail: | one 40'HQcontainer within 15 working days |

Specifications

our woven geotextile have superior properties for filtration, separation, reinforcement, erosion control

1.About Us

Company Profile :

We have more than 25 years experience in development & manufacture synthetics like woven geotextile , geotube,silt curtain,concrete filling mattress,pile jacket and industrial

fabric. Depending on our full set production line, well equipped laboratory, cooperation with

institute& college and experienced employees, we havesuccessfully developed and

consolidated domestic and foreign market.

2.Products

Woven geotextile :

Made from polypropylene and or polyester fibers, manufactured with high tensile strength and low elongation, our woven geotextiles have superior properties for filtration, separation, reinforcement, erosion control and drainage. We are leader in providing woven geotextiles for a variety of civil and environmental applications including highways, port facilities, reservoir, transport construction, waste and chemical management ,subgrade engineering, coast reclamation works, peninsula shoal engineering.

Properties of Multifilament Woven Geotextile

Metric and British conversions:

1kn/m------around68.57lbs/ft 1oz/yd2---around 33.9g/m2 1m------around 3.3ft

Physical properties | Test method | Unit | Typical Value | ||||||||||

Material | Polypropylene/PP | ||||||||||||

Unit Weight | ASTM D 5261 | g/m2 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1300 | ||

Color | White | ||||||||||||

Tensile Strength at break MD | ASTM D 4595 | KN/M >= | 50 | 75 | 100 | 130 | 160 | 180 | 200 | 230 | 360 | ||

Tensile Strength at break CD | ASTM D 4595 | KN/M >= | 35 | 52 | 70 | 90 | 112 | 126 | 140 | 160 | 280 | ||

Elongation at break MD | ASTM D 4595 | % <= | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | ||

Elongation at break CD | ASTM D 4595 | % <= | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | ||

CBR Puncture Strength | ASTM D 6241 | KN | 4 | 6.9 | 10.5 | 14 | 18 | 20.5 | 23 | 24 | 28 | ||

Tear Strength | ASTM D 4533 | KN | 0.6 | 1 | 1.3 | 1.55 | 1.9 | 2 | 2.2 | 2.3 | 3.2 | ||

Permitivity | ASTM D 4491 | S-1 | 0.01-0.8 | ||||||||||

Pore opening size O90 | ASTM D 4751 | mm | 0.06-0.7 | ||||||||||

Width: max 3.8m, standard 3.6m. Other colors available. | |||||||||||||

Physical properties | Test method | Unit | Typical Value | |||||||

Material | Polyester/PET | |||||||||

Color | White | |||||||||

Tensile Strength at break MD | ASTM D 4595 | KN/M | 100 | 150 | 150 | 200 | 400 | 300 | 500 | 1000 |

Tensile Strength at break CD | ASTM D 4595 | KN/M | 50 | 50 | 150 | 50 | 50 | 300 | 100 | 50 |

Elongation at break MD | ASTM D 4595 | % | <=15 | |||||||

Elongation at break CD | ASTM D 4595 | % | <=15 | |||||||

Permitivity | ASTM D 4491 | S-1 | 0.01-0.8 | |||||||

Pore opening size O90 | ASTM D 4751 | mm | 0.06-0.7 | |||||||

- Q:In ANSYS, geotextile what unit to simulate it?

- I am now doing geotextile simulation, before someone with shell63, I now use, but the shell and the physical contact I did a long time. The

- Q:Seepage geotextile symbol

- I produce geotextile materials

- Q:Are geotextiles resistant to insect infestation?

- Yes, geotextiles are generally resistant to insect infestation. Their synthetic material and tightly woven structure make it difficult for insects to penetrate or nest within the fabric. However, it is important to note that while geotextiles provide a barrier against insects, they are not completely immune to all types of infestation.

- Q:How do geotextiles help in preventing soil erosion in vineyards?

- Geotextiles help prevent soil erosion in vineyards by providing a protective barrier between the soil and external factors such as rain, wind, and water runoff. These textile materials effectively stabilize the soil by minimizing surface erosion, controlling sediment movement, and promoting the retention of moisture. Additionally, geotextiles enhance soil structure and allow for better root growth, preventing the loss of valuable topsoil and preserving the vineyard's overall health and productivity.

- Q:What are the specifications for geotextiles in railway projects?

- The specifications for geotextiles in railway projects generally include requirements for strength, durability, permeability, and filtration. These geotextiles should have sufficient tensile strength to withstand the dynamic loads imposed by trains and maintain their integrity over time. They should also be resistant to degradation caused by UV exposure, chemical exposure, and biological factors. The permeability of geotextiles is crucial to ensure proper drainage and prevent water accumulation, which can lead to instability. Additionally, the geotextiles should possess excellent filtration properties to prevent the migration of fine particles and maintain the stability of the railway subgrade.

- Q:What are the cost considerations for geotextile applications?

- Some cost considerations for geotextile applications include the initial purchase cost of the geotextile material, the cost of installation, and any additional costs associated with site preparation and maintenance. Other factors such as the size and complexity of the project, the type and quality of the geotextile material, and the expected longevity of the application also contribute to the overall cost. Additionally, the potential cost savings from using geotextiles, such as reduced construction time and improved long-term performance, should also be taken into account.

- Q:How are geotextiles affected by temperature variations?

- Geotextiles are affected by temperature variations as they can expand or contract based on the temperature changes. This expansion or contraction can impact their effectiveness in various applications such as erosion control, filtration, or drainage. Additionally, extreme temperatures can weaken the fibers of geotextiles, reducing their overall durability and lifespan. Therefore, temperature variations need to be considered while selecting and designing geotextile systems to ensure their optimal performance and longevity.

- Q:How are geotextiles tested for quality assurance?

- Geotextiles are tested for quality assurance through a series of standardized tests and evaluations. These include physical properties testing such as tensile strength, tear resistance, and puncture strength, as well as hydraulic properties testing like permeability and filtration efficiency. Additionally, durability and chemical resistance tests are conducted to ensure the geotextiles can withstand long-term exposure to various environmental conditions. These rigorous quality assurance measures help to determine the performance and suitability of geotextiles for specific applications.

- Q:How do geotextiles affect soil properties?

- Geotextiles can significantly impact soil properties by improving stability, erosion control, filtration, and drainage. They act as a barrier to prevent soil erosion and retain soil particles, enhancing the stability of slopes and embankments. Geotextiles also enhance filtration by allowing water to pass through while retaining sediments, which improves water quality. Additionally, they enhance drainage by facilitating the flow of water through the soil, preventing waterlogging and maintaining optimal soil moisture levels. Overall, geotextiles play a crucial role in improving soil properties and protecting against erosion and other soil-related issues.

- Q:How do geotextiles help with soil stabilization in steep slopes?

- Geotextiles help with soil stabilization in steep slopes by providing reinforcement and preventing erosion. When placed on the slope, geotextiles act as a barrier, holding the soil in place and preventing it from sliding or eroding downhill. The geotextiles also allow water to pass through while retaining the soil, reducing the impact of heavy rainfall or water flow on the slope. This helps to maintain the integrity of the slope, preventing landslides and ensuring long-term stability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Geotextile Woven PP Earthwork for Road and Railway

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords