FRP Grating, FRP Molded Grating, FRP Fiberglass Plastic Walkway Grating with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

l Corrosion Resistance

l Fire Resistance

l Light Weight & High Strength

l Safety & Anti-slip

l Electrical Insulating

l Aging Resistance

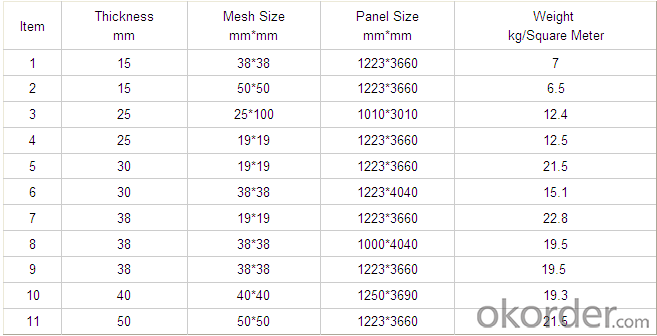

Specification

Advantage

1) coated with prevent aging layer

2) excellent insulating performance

3) no maintenance

4) high strength

5) long service life

6) easy installation

Application

l Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

l In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

l Pool railings in sewage treatment industry

l Corrosive chemical industry equipment around the fence

l All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

5. How is the package?

Usually, we arrange the standard out-package for exporting.

PROCESS

FACTORY

- Q:FRP pultrusion process?

- Reinforcement materials used in pultrusion processes, mainly glass fibers and their products, such as roving, continuous fiber felt, etc.. In order to meet the special requirements of the products, aramid fiber, carbon fiber and metal fiber can be used. No matter which fiber is used in the pultrusion process, the surface must be treated so that it can be well bonded with the resin matrix.

- Q:Can FRP pultrusion profiles be used in the construction of theme park rides?

- Yes, FRP pultrusion profiles can be used in the construction of theme park rides. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various structural applications. These profiles can be used to build ride components such as supports, beams, frames, and safety structures, providing a lightweight yet robust solution for theme park rides.

- Q:Are FRP pultrusion profiles fire resistant?

- Yes, FRP pultrusion profiles are fire resistant.

- Q:Can FRP pultrusion profiles be used in wastewater treatment facilities?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in wastewater treatment facilities. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, which make them suitable for use in harsh environments like wastewater treatment facilities. In wastewater treatment facilities, there are various applications where FRP pultrusion profiles can be used. These include but are not limited to walkways, handrails, ladders, grating, and structural supports. The corrosion resistance of FRP makes it ideal for use in areas exposed to moisture and chemicals present in wastewater. Furthermore, FRP profiles are lightweight, which simplifies installation and reduces the load on supporting structures. The durability of FRP pultrusion profiles ensures long-term performance, even in aggressive environments. They have a high resistance to chemical attack, UV radiation, and bacterial growth, making them suitable for wastewater treatment applications. Additionally, FRP profiles can be designed to meet specific load requirements and can be easily fabricated to fit various shapes and sizes. Moreover, FRP pultrusion profiles offer excellent electrical insulation properties, which can be advantageous in wastewater treatment facilities where electrical safety is a concern. In summary, FRP pultrusion profiles can be effectively used in wastewater treatment facilities due to their corrosion resistance, durability, lightweight nature, and versatility in design and fabrication. These profiles can provide long-lasting solutions for various applications within these facilities, ensuring operational efficiency and minimizing maintenance requirements.

- Q:How do FRP pultrusion profiles handle bending and flexing?

- FRP pultrusion profiles are designed to handle bending and flexing exceptionally well due to their inherent structural properties. The combination of reinforcing fibers, such as fiberglass, and a polymer resin matrix in the pultruded profiles results in high strength and stiffness. This allows the profiles to withstand bending forces without any significant deformation or failure. Additionally, the ability of FRP to withstand flexing is attributed to its high fatigue resistance, making it suitable for applications that require repeated bending or flexing movements.

- Q:How do FRP pultrusion profiles perform in seismic zones?

- Due to their inherent properties and characteristics, FRP pultrusion profiles are highly suitable for use in seismic zones. One of the main advantages of these profiles is their excellent strength-to-weight ratio, which allows them to effectively withstand seismic forces without adding significant weight to the structure. In seismic zones, structures and buildings experience intense ground motions during an earthquake. FRP pultrusion profiles possess high stiffness and strength, enabling them to effectively resist the lateral forces caused by seismic activity. These profiles have a high modulus of elasticity, allowing them to maintain their shape and structural integrity even under extreme seismic loads. Furthermore, FRP pultrusions exhibit outstanding corrosion resistance, making them highly durable in seismic zones. Unlike traditional materials like steel or concrete, FRP profiles do not corrode when exposed to moisture, chemicals, or salts commonly found in seismic regions. This corrosion resistance ensures the long-term performance and structural integrity of FRP pultrusion profiles, even in harsh environmental conditions. Another advantage of FRP pultrusions in seismic zones is their flexibility and ability to dampen vibrations. During an earthquake, ground motions cause structures to vibrate. The inherent damping properties of FRP materials help absorb and dissipate these vibrations, reducing the potential for structural damage. Additionally, FRP pultrusion profiles can be designed and manufactured to meet specific seismic requirements and codes. They can be reinforced with additional layers or designed with specific geometries to enhance their seismic performance, ensuring compliance with necessary safety standards in seismic zones. Overall, FRP pultrusion profiles offer numerous benefits for use in seismic zones. Their high strength-to-weight ratio, corrosion resistance, damping properties, and design flexibility make them an excellent choice for constructing seismic-resistant structures while ensuring durability and safety.

- Q:Do FRP pultrusion profiles have any limitations or drawbacks?

- FRP pultrusion profiles indeed have certain limitations and drawbacks that need to be taken into account. One of these limitations is their lower stiffness compared to traditional materials like steel or aluminum. As a result, they may not be suitable for applications that demand high structural rigidity or heavy loads. Another constraint is their susceptibility to creep, which refers to the gradual deformation of the material under a constant load over time. This can adversely affect the long-term performance and durability of the profiles, particularly in scenarios where they face sustained stress. Moreover, FRP pultrusion profiles generally incur higher production costs compared to traditional materials. The manufacturing process involves pultruding continuous fibers through a resin matrix, requiring specialized equipment and expertise. Consequently, the higher production expenses make FRP pultrusion profiles less economically viable for certain applications. Additionally, FRP pultrusion profiles are typically not suitable for high-temperature applications. The resin matrix used in their production can degrade or soften at elevated temperatures, thereby restricting their use in environments where thermal resistance is crucial. Finally, FRP pultrusion profiles may have limited design flexibility compared to other materials. The pultrusion process typically yields profiles with constant cross-sections and limited geometric complexity. Consequently, their use is restricted in applications that necessitate intricate shapes or customized designs. Despite these limitations, FRP pultrusion profiles offer several advantages, such as a high strength-to-weight ratio, corrosion resistance, and electrical insulation properties. Therefore, it is crucial to thoroughly consider the specific requirements of the application before opting for FRP pultrusion profiles.

- Q:Can FRP pultrusion profiles be used in infrastructure projects?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in infrastructure projects. FRP pultrusion profiles offer several advantages over traditional materials such as steel and concrete. Firstly, FRP profiles are lightweight, yet still possess high strength-to-weight ratios. This makes them easier to transport and install, reducing construction time and costs. Additionally, their lightweight nature ensures they do not exert excessive loads on the supporting structures. Secondly, FRP profiles are corrosion-resistant. Unlike steel, FRP does not rust or corrode when exposed to harsh environmental conditions, making them ideal for infrastructure projects located in coastal areas or regions with high humidity. This corrosion resistance extends the service life of the structures and reduces maintenance requirements, resulting in long-term cost savings. Thirdly, FRP pultrusion profiles offer excellent durability and dimensional stability. They are highly resistant to fatigue, creep, and environmental degradation, ensuring the longevity and structural integrity of the infrastructure. Their dimensional stability also means that they maintain their shape and structural properties over time, reducing the risk of deformation or failure. Furthermore, FRP profiles can be customized to meet specific project requirements. They can be manufactured in various shapes, sizes, and strengths, allowing for versatile applications in infrastructure projects such as bridges, walkways, railings, support structures, and utility poles. Overall, the use of FRP pultrusion profiles in infrastructure projects offers numerous advantages, including lightweight construction, corrosion resistance, durability, and customization options. These benefits make FRP profiles a viable and cost-effective alternative to traditional materials for various infrastructure applications.

- Q:What are the different shapes and sizes of FRP pultrusion profiles available?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are available in a wide range of shapes and sizes to cater to various applications and industries. Some of the commonly available shapes include: 1. Square and rectangular profiles: These profiles are available in different sizes and are widely used in construction, infrastructure, and industrial applications. They offer excellent structural strength and can be used as beams, columns, or other load-bearing elements. 2. Round profiles: Round FRP pultrusion profiles are often used as structural supports, handrails, and guardrails. They are available in various diameters to suit different requirements. 3. I-beams: FRP I-beams are popular in the construction industry due to their high strength-to-weight ratio. They are often used as structural members, supporting elements, or floor joists. 4. Channel profiles: Channel-shaped FRP profiles are used for applications that require a combination of strength and versatility. They find applications in cable trays, equipment supports, and framing systems. 5. Angle profiles: FRP angle profiles are commonly used as reinforcements or supports in construction and industrial settings. They provide stability and structural integrity to various components. 6. Custom profiles: Apart from the standard shapes mentioned above, FRP pultrusion profiles can also be customized to meet specific requirements. Manufacturers can create profiles with unique shapes and sizes to suit the needs of different applications. It is important to note that the availability of shapes and sizes may vary among manufacturers. Therefore, it is advisable to consult with suppliers or manufacturers to determine the specific range of FRP pultrusion profiles they offer.

- Q:How do FRP pultrusion profiles perform in extreme cold temperatures?

- Due to the properties of the materials used, FRP pultrusion profiles perform exceptionally well in extremely cold temperatures. These profiles, made of FRP composites, are known for their excellent thermal insulation properties, which help maintain their structural integrity even in low temperatures. One major advantage of FRP pultrusion profiles in cold environments is their ability to resist freezing and thawing cycles. Unlike other materials, FRP does not absorb water, thus preventing expansion or contraction with temperature changes. This eliminates the risk of cracking or damage that can occur when moisture freezes and expands within traditional materials like metal or concrete. Moreover, FRP pultrusion profiles have a low coefficient of thermal expansion, meaning they do not significantly expand or contract with temperature fluctuations. This stability allows them to maintain their shape and structural integrity in extreme cold, reducing the chances of deformation or failure. Aside from their thermal properties, FRP pultrusion profiles also exhibit high strength and durability, making them suitable for various applications in construction, infrastructure, and transportation, even in harsh cold environments. They are resistant to corrosion, chemicals, and UV radiation, further enhancing their performance and longevity in extreme conditions. In conclusion, FRP pultrusion profiles are an excellent choice for applications requiring reliable performance in extreme cold temperatures. With their thermal insulation properties, resistance to freezing and thawing cycles, low coefficient of thermal expansion, and overall strength and durability, they are well-suited for various industries and environments, ensuring their continued performance even in the harshest cold conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Grating, FRP Molded Grating, FRP Fiberglass Plastic Walkway Grating with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords