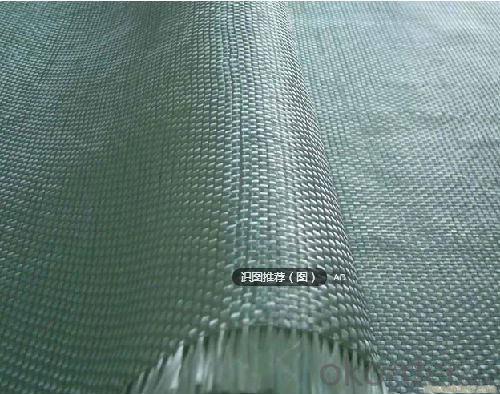

Fiberglass Fabrics with Medium Silica

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction:

Medium silica fabrics can be used for a long period of time without changing their properties perat the temperature of 800℃ as it contains more than 70%±5% silica.

2.Properties

No asbestos orceramic,no harm to human

Low thermal conductivity,excellent thermal insulation

Superb electric insulation

Inert to majority of chemical reagents

Good flexibility

3.Application

Fire fighting

High temperature gas filtration

Thermal insulation

4.Specification

| Type | Weave Type | Area Weight | Width cm | Thickness | Warp Yarns/cm | Weft yarns/cm |

| RS-600 | Satin 8HS | 600±50 | 100 | 0.75±0.1 | 18±1 | 13±1 |

| RS-1100 | Satin 12HS | 1100±50 | 100 | 1.35±0.1 | 18±1 | 13±1 |

5.Package and Delivery Time.

Packed with carton and pallets.The products will be ready in 15-20 days after the order confirmation.

FAQ:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q:Can fiberglass fabric be used for acoustic insulation?

- Yes, fiberglass fabric can be used for acoustic insulation. Fiberglass fabric is known for its excellent sound-absorbing properties, making it an ideal material for acoustic insulation. It can effectively reduce noise by absorbing sound waves, preventing them from bouncing off hard surfaces and creating echoes or reverberations. Fiberglass fabric is commonly used in various applications such as wall panels, ceiling tiles, and acoustic curtains to improve sound quality and reduce unwanted noise in spaces such as theaters, recording studios, and offices. Additionally, fiberglass fabric is lightweight, durable, and easy to install, making it a popular choice for acoustic insulation solutions.

- Q:What is the difference between glass fiber plain cloth and glass fiber grid cloth? What are the specifications and specifications of plain cloth and square cloth?

- Glass fiber plain woven fabric refers to the warp and weft at 90 angles up and down weaving woven fabric. In the glass fiber industry, usually spinning (monofilament diameter less than 9 microns) to weave. In addition to the plain method, can also use different weave twill or satin weave etc..

- Q:Can fiberglass fabric be used for making protective covers?

- Fiberglass fabric has the ability to be used in the creation of protective covers. This material is widely recognized for its exceptional strength and durability, making it an ideal choice for safeguarding against a multitude of elements, including heat, chemicals, and abrasions. Its fire-resistant nature and resistance to melting make it particularly suitable for situations where fire safety is of utmost importance. Additionally, fiberglass fabric is lightweight and flexible, allowing for effortless handling and installation. It can be utilized to construct protective covers for a diverse range of items, such as equipment, machinery, vehicles, as well as personal protective gear like gloves and aprons. In summary, fiberglass fabric is highly regarded for its superior protective properties and is extensively utilized across various industries for the production of protective covers.

- Q:What are the different fiberglass fabric weaves for high strength applications?

- There are several different fiberglass fabric weaves that are commonly used for high strength applications. These weaves include plain weave, twill weave, satin weave, and leno weave. 1. Plain weave: This is the most basic and common weave pattern. It consists of an over-under pattern, where each warp yarn goes over and under each weft yarn. Plain weave fabrics provide excellent strength and dimensional stability, making them suitable for a wide range of high strength applications. 2. Twill weave: Twill weave is characterized by a diagonal pattern created by the interlacing of warp and weft yarns. This weave is known for its strength and durability. Twill weave fabrics offer good drapability, making them ideal for applications that require flexibility and resistance to wrinkling. 3. Satin weave: Satin weave is characterized by long floats, where the warp or weft yarns skip over multiple yarns in the opposite direction. This creates a smooth and lustrous surface. Satin weave fabrics have excellent strength and are commonly used in applications where a high-quality finish is desired, such as aerospace components and luxury goods. 4. Leno weave: Leno weave is a unique weave pattern that involves twisting adjacent warp yarns around each weft yarn. This creates a stable and open structure with good strength and stability. Leno weave fabrics are commonly used in high strength applications where breathability and lightness are important, such as in filtration systems and composites. These different fiberglass fabric weaves offer varying degrees of strength, flexibility, and durability, allowing manufacturers to choose the most suitable weave for their specific high strength applications.

- Q:Can fiberglass fabrics be used for insulation in HVAC systems?

- Yes, fiberglass fabrics can be used for insulation in HVAC systems. Fiberglass is a popular choice for insulation in HVAC systems due to its excellent thermal properties. It has a low thermal conductivity, which means it can effectively resist heat transfer. Fiberglass fabrics are typically used to cover air ducts, pipes, and other components in HVAC systems to prevent heat loss or gain. Fiberglass fabrics also have other beneficial properties that make them suitable for insulation. They are lightweight, flexible, and easy to install, making them a convenient choice for HVAC insulation. Additionally, fiberglass fabrics are resistant to moisture, mold, and mildew, which helps in maintaining good indoor air quality. Furthermore, fiberglass fabrics have excellent fire-resistant properties. They are non-combustible and do not release toxic gases when exposed to high temperatures. This makes them a safe choice for insulation in HVAC systems. Overall, fiberglass fabrics can be effectively used for insulation in HVAC systems due to their thermal efficiency, ease of installation, moisture resistance, and fire safety.

- Q:Problems in making FRP models and models

- The bottom and the canopy, this can be directly on the bottom mold the glass fiber cloth can pave the way. Glass fiber cloth can be bent into irregular surface to a certain extent. But this seems to be called "stretch", but change it in different position of the mesh density. In other words, so make the canopy around the grid the top of the grid density, density is small.

- Q:Are there any specific safety precautions to consider when working with fiberglass fabrics?

- There are multiple safety precautions to take into account when working with fiberglass fabrics. To begin with, it is crucial to utilize suitable personal protective equipment (PPE) such as gloves, goggles, and a respirator. Minimizing direct contact and inhalation of the fiberglass fibers is essential due to their potential to irritate the skin, eyes, and respiratory system. In addition, it is advisable to either work in a well-ventilated area or employ local exhaust ventilation to decrease the concentration of airborne fiberglass particles. This measure helps in preventing respiratory issues caused by inhaling the fibers. Furthermore, it is important to handle fiberglass fabrics with caution to avoid generating dust or releasing loose fibers. Cutting or sanding fiberglass fabrics should be carried out in a controlled manner by using wet techniques or dust collection systems to reduce airborne particles. When it comes to cleaning up after working with fiberglass fabrics, it is recommended to use a damp cloth or a vacuum cleaner equipped with a HEPA filter to capture any loose fibers. Avoid dry sweeping or using compressed air as these methods can disperse the fibers into the air. Lastly, it is worth noting that storing fiberglass fabrics in a dry area is crucial to prevent moisture absorption, which can negatively impact their performance and durability. By adhering to these safety precautions, individuals can effectively minimize the potential health risks associated with working with fiberglass fabrics.

- Q:Can fiberglass fabric be used for heat shields?

- Yes, fiberglass fabric can be used for heat shields. Fiberglass is known for its excellent thermal insulation properties, making it an ideal material for heat shields. It can withstand high temperatures without deforming or melting, which is crucial for protecting sensitive equipment or structures from heat damage. Additionally, fiberglass fabric is also lightweight, flexible, and can be easily molded or cut into desired shapes, allowing for easy installation in various applications where heat protection is required.

- Q:Is fiberglass fabric resistant to UV degradation in outdoor applications?

- Fiberglass fabric, indeed, boasts a remarkable resistance to UV degradation when utilized outdoors. Its composition consists of fibers deliberately crafted to endure extended exposure to sunlight and various environmental elements. Moreover, the fabric undergoes treatment with exclusive coatings or finishes that furnish supplementary safeguarding against UV radiation. This exceptional UV resistance renders fiberglass fabric an optimal selection for outdoor purposes that entail sunlight exposure, such as awnings, canopies, and outdoor furniture. Furthermore, fiberglass fabric retains its durability and integrity even after enduring years of UV ray exposure, guaranteeing its enduring performance in outdoor environments.

- Q:What are the different fiberglass fabric finishes for chemical resistance?

- Various fiberglass fabric finishes are available to provide chemical resistance. These finishes are specifically designed to safeguard the fiberglass fabric against the detrimental effects of different chemicals, rendering it suitable for use in industries where exposure to corrosive substances is prevalent. Some of the options for chemical-resistant fiberglass fabric finishes are as follows: 1. Vinyl Finish: By applying a coating of vinyl resin to the fiberglass fabric, this finish ensures exceptional chemical resistance. Vinyl is renowned for its ability to withstand a wide range of chemicals, including acids, alkalis, oils, and solvents. The vinyl finish acts as a protective barrier between the fabric and the chemicals, preventing any damage or degradation. 2. Fluoropolymer Finish: Fluoropolymer finishes, such as PTFE (polytetrafluoroethylene) or FEP (fluorinated ethylene propylene), exhibit outstanding chemical resistance. These finishes create a non-stick surface that repels most chemicals, making them highly suitable for applications where the fabric may come into contact with aggressive substances. 3. Neoprene Finish: Neoprene, a synthetic rubber, is well-known for its excellent resistance to oils, acids, alkalis, and solvents. Fiberglass fabric with a neoprene finish can endure exposure to a wide array of chemicals without deteriorating or compromising its structural integrity. 4. Polyurethane Finish: Offering good chemical resistance, polyurethane finishes provide additional advantages such as enhanced abrasion resistance and flexibility. This finish is commonly utilized in applications where the fabric must endure exposure to chemicals as well as physical wear and tear. 5. Silicone Finish: Silicone finishes exhibit remarkable resistance to high temperatures and a diverse range of chemicals. They establish a protective layer on the fiberglass fabric, guarding it against chemical attack and degradation. Consequently, silicone finishes are ideal for usage in environments involving aggressive substances or extreme conditions. It is worth noting that the selection of a fiberglass fabric finish for chemical resistance depends on the specific chemicals to which it will be exposed and the operating conditions of the particular application. Seeking guidance from a knowledgeable supplier or manufacturer can assist in determining the most suitable finish for a specific chemical-resistant fiberglass fabric.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Fabrics with Medium Silica

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords