Fiberglass Fabrics High Silica Good Quality and Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction:

High silica fabrics can be used for a long period of time without changing their properties perat the temperature of 1000℃ as it contains more than 96% silica.

2.Properties

No asbestos orceramic,no harm to human

Low thermal conductivity,excellent thermal insulation,high resistance to thermal shock

Superb electric insulation

Inert to majority of chemical reagents

Good flexibility

3.Application

Aerospace,nuclear

Shipbuilding,machinery industry

Refinery

Metallurgy, auto industry

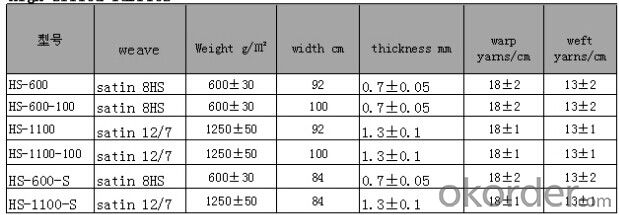

4.Specification

5.Package and Delivery Time.

Packed with carton and pallets.The products will be ready in 15-20 days after the order confirmation.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q:Is fiberglass fabric resistant to chemicals used in mining?

- Yes, fiberglass fabric is highly resistant to chemicals used in mining. It is specifically designed to withstand harsh conditions and is known for its exceptional chemical resistance. Fiberglass fabric is impervious to most acids, alkalis, solvents, and other chemicals commonly used in mining operations. This makes it an ideal material for various applications in the mining industry, such as lining tanks, pipes, and other equipment that come into contact with corrosive substances. Furthermore, fiberglass fabric is also resistant to high temperatures, abrasion, and wear, making it a durable and reliable choice in mining environments.

- Q:How does fiberglass fabric perform in fire resistance?

- Fiberglass fabric is highly fire-resistant. It does not catch fire easily and can withstand high temperatures without melting or burning. It is often used in applications where fire safety is a concern, such as in fire curtains, protective clothing, and insulation materials.

- Q:Is fiberglass fabric resistant to electrical conductivity?

- Yes, fiberglass fabric is resistant to electrical conductivity.

- Q:What are the different fiberglass fabric weaves for thermal insulation?

- For thermal insulation purposes, there exist multiple types of fiberglass fabric weaves that are commonly utilized. These weaves are specifically designed to offer exceptional heat resistance and insulation capabilities. The plain weave is one of the most frequently employed weaves for thermal insulation. It is characterized by a straightforward over-under pattern, where each weft thread alternates between passing over and under each warp thread. This particular weave is renowned for its balanced strength and stability, rendering it suitable for a wide array of applications. Another popular option for thermal insulation is the satin weave. This weave is distinguished by a succession of floating warp or weft threads that traverse over several consecutive threads prior to intertwining again. As a result, the satin weave produces a smooth and lustrous fabric with a high degree of flexibility and drapability. It is an ideal choice for scenarios that necessitate a lightweight and flexible insulation solution. The twill weave, featuring a diagonal pattern created by the interlacing of warp and weft threads, is another viable alternative for fiberglass fabric used in thermal insulation. Twill weaves are celebrated for their strength and durability, making them a suitable option for applications demanding a more robust insulation solution. Furthermore, the leno weave is frequently employed for thermal insulation purposes. This weave entails the twisting of adjacent warp threads around one another to generate small, open spaces within the fabric. These spaces facilitate improved air circulation and moisture management, positioning leno weave fabrics as an excellent choice for situations where breathability is crucial. Ultimately, the selection of a fiberglass fabric weave for thermal insulation will depend on the specific requirements of the application, encompassing desired insulation properties, flexibility, strength, and breathability.

- Q:How does fiberglass fabric perform in terms of sound absorption?

- Known for its exceptional sound absorption properties, fiberglass fabric is widely acknowledged. Its unique composition and structure enable it to effectively soak up sound waves, thereby diminishing echoes and reverberations within a designated area. By virtue of its density and porous nature, the fabric can trap and dissipate sound energy, preventing its rebound into the room. Consequently, fiberglass fabric has become a favored option for soundproofing needs across various industries, including recording studios, theaters, and commercial buildings. Furthermore, it finds utility in wall panels, acoustic curtains, and other sound-absorbing products, augmenting the overall acoustic performance of a space. In summary, fiberglass fabric is highly esteemed for its sound absorption capabilities, contributing to enhanced sound quality and decreased noise levels in any given environment.

- Q:What are the different fiberglass fabric coatings for moisture resistance?

- There are several different fiberglass fabric coatings available for moisture resistance. One popular option is a silicone coating, which provides excellent water repellency and can withstand high temperatures. Silicone coatings also offer flexibility and durability, making them suitable for various applications. Another common choice is an acrylic coating. Acrylic coatings are water-based and provide good resistance to moisture and mildew. They are often used in outdoor applications where exposure to rain or other moisture is a concern. Polyurethane coatings are another option, known for their excellent moisture resistance and flexibility. They provide a strong barrier against water penetration and can be applied in a variety of thicknesses to meet specific requirements. Epoxy coatings are also used for moisture resistance on fiberglass fabric. These coatings are highly resistant to water, chemicals, and abrasion. They provide a durable and protective layer that helps prevent moisture damage. It is important to consider the specific requirements of the project when choosing a fiberglass fabric coating for moisture resistance. Factors such as the level of moisture exposure, temperature range, and desired durability should be taken into account. Consulting with a professional or manufacturer can help determine the most suitable coating option for a particular application.

- Q:Can fiberglass fabric be used for heat shields?

- Yes, fiberglass fabric can be used for heat shields. Fiberglass is known for its excellent thermal insulation properties, making it an ideal material for heat shields. It can withstand high temperatures without deforming or melting, which is crucial for protecting sensitive equipment or structures from heat damage. Additionally, fiberglass fabric is also lightweight, flexible, and can be easily molded or cut into desired shapes, allowing for easy installation in various applications where heat protection is required.

- Q:Mural and wallpaper are different, which should pay attention to choosing murals?

- Murals and wallpaper are two concepts, the murals are a custom-made pattern, according to the actual size of the wall made, and wallpaper is a regular pattern, so murals are usually used for local posting.

- Q:What are the maintenance requirements of fiberglass fabric?

- The maintenance requirements of fiberglass fabric are relatively low compared to other materials. However, there are still a few things to keep in mind to ensure the longevity and optimal performance of fiberglass fabric. Firstly, regular cleaning is necessary to remove any dirt, dust, or debris that may accumulate on the surface of the fabric. This can be done by gently vacuuming or using a soft brush to remove loose particles. Avoid using harsh chemicals or abrasive cleaners, as they can potentially damage the fabric. In addition to cleaning, it is important to inspect the fabric periodically for any signs of wear or damage. Look for any fraying, tears, or loose threads, and address them promptly to prevent further deterioration. If any repairs are needed, it is recommended to consult a professional or follow the manufacturer's instructions for proper repair techniques. It is also advisable to protect fiberglass fabric from excessive exposure to sunlight, as prolonged exposure to UV rays can cause fading or discoloration. Using UV-resistant coatings or treatments can help mitigate this issue and prolong the fabric's lifespan. Lastly, storing fiberglass fabric properly when not in use is crucial for maintaining its quality. Ensure that it is kept in a clean and dry environment, away from moisture or extreme temperatures. Rolling or folding the fabric neatly and avoiding any sharp objects or heavy items on top of it will help prevent creasing or damage during storage. By following these maintenance requirements, fiberglass fabric can retain its durability, appearance, and functionality for an extended period of time, making it a reliable choice for various applications.

- Q:Is fiberglass fabric suitable for use in architectural membranes?

- Yes, fiberglass fabric is suitable for use in architectural membranes. It offers several advantages such as high strength, durability, and fire resistance. Additionally, fiberglass fabric can be lightweight and flexible, making it ideal for creating unique and innovative architectural designs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Fabrics High Silica Good Quality and Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords