Calcium Silicate Insulation Block Sheet Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Calcium Silicate Boards) Description

1.Obtained CE, KR and ISO9001;

2.Heat resistance temperature is up to 1100 degree centigrade;

3.Low price and best quality.

Description of our products

Calcium Silicate Board is a kind of high efficiency energy-saving and Environmentally friendly materials with temperature limited 1150 cent-degree. They are recommended as thermal insulations of equipment in power station, steel mill and petrochemical industries as well as other various fields. It can be used in washrooms as the ceiling, partition and backer boards. Additionally, Due to the features of fire prevention, thermal insulation, mildew proof and moisture proof, are also applicable to places where high security is needed.

Advantages of our products

1. we have own factory to produce the boards, and we are not the trading company, so we would have the directly customer service and the warranty of our boards is very good;

2. We obtained CE, KR and ISO9001;

3. The highest heat resistance temperature is up to 1100 degree centigrade;

4.The maximum flexural strength is up to 0.7MPa, all technical parameters are the best in China, it is better than other calcium silicate board in the market.

5.Our factory is corporate with the big power plant, uses the steam of the power plant to product the board, it is different from other factories to produce with the boiler. The product use the steam, the quality is better than use the boiler, so the technical parameters of our product are the best in factory. And it is very easy to mass product and reduce the waste, the cost is lower than our factory use boiler. So that the product from our factory is best quality and cheapest price.

2,Main Features of the (Calcium Silicate Boards)

Types of products

1. Standard type Calcium Silicate Board

2. JN High-temp Type Calcium Silicate Board

3. High density Calcium Silicate Insulation material Board

4. High strength calcium silicate boards

5. Core Board of Fire Door

6.External wall calcium silicate board

7.Thermal insulation pipe cover

8. Light weight low thermal conductivity calcium silicate board 130kg/m³

Product advantage :

Excellent chemical stability

Low thermal conductivity;

Low heat capacity;

Excellent sound absorption and noise reduction performance

Physical performance data:

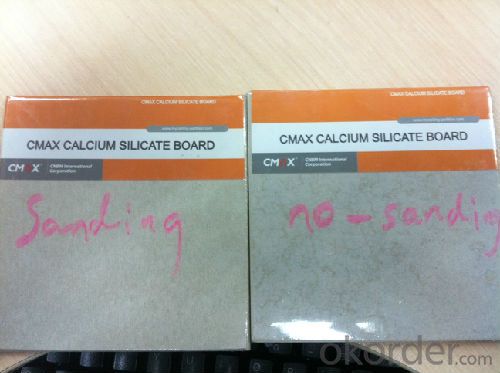

3,(Calcium Silicate Boards) Images

4,(Calcium Silicate Boards) Specification

Physical tech datas | 170 | 220 | 240 |

Density(kg/m3) | 170 | 220 | 240 |

Quality moisture content(%) | ≤7.5 | ≤7.5 | ≤7.5 |

Compressive strength(Mpa) | ≥0.40 | ≥0.50 | ≥0.50 |

Flexural strength(Mpa) | ≥0.20 | ≥0.30 | ≥0.30 |

Termal conductivity(W/m.k) | 0.058 | 0.062 | 0.062 |

Work temperature | 650 | 650 | 650 |

Linear shrinkage(%) | ≤2 | ≤2 | ≤2 |

Size | 600*300*25-100mm, 500*500*25-100mm | ||

Length(±3 mm) mm | Width(±3 mm) mm | thickness(+2 mm-1.5mm) |

1260 | 1260 | 50--120 |

1000 | 500 | 50--120 |

600 | 400 | 40--120 |

600 | 300,150 | 30--140 |

500 | 500 | 50--120 |

400 | 250 | 25--140 |

Products with max. service temp. of 1050°C are also available here.

5,FAQ of (Calcium Silicate Boards)

Application:

Petrochemical industry

Iron & steel industry

Cement industry

Glass industry

Shipping industry

- Q:Calcium silicate board water absorption on the performance of the plate have any effect

- The absorption of water vapor moisture is not enough to change the performance of the plate, and low density stability better, so the site recommended the use of low-density sheet, because the lighter the lighter the better.

- Q:How to identify whether calcium carbonate board contains asbestos?

- Asbestos calcium silicate board broken mouth will be very fine very fine wool (is plant fiber), after the fire is lit, is the smell of wood burning, no special smell; with asbestos calcium silicate board broken mouth will have Rough wool (asbestos), with the fire lit, there will be a very special smell, like the smell of plastic burning.

- Q:What is the specific difference between the silicate board and the calcium silicate board?

- Due to the repetition of the noun, it was fake, of course, some people come out to clarify: "Calcium silicate board and" calcium calcium gypsum board "has nothing to do? Isolated. Calcium silicate board is the international general high-grade ceiling wall materials, Japan, the United States, Western Europe, Southeast Asia and other regions are commonly used in the construction of sheet metal in China, to JC / T564-2000 provides its name for the calcium silicate board. Calcium silicate board was introduced to China production, although less than 15 years, Excellent performance is widely recognized by the market. "Silicon calcium gypsum board" and claiming to be "silicon calcium board", although the title of "silicon calcium", but in fact is a certain improvement of the gypsum board or even purely ordinary gypsum board, trying to confuse the calcium silicate board. So far, there is no national or building materials industry standards for this product "named".

- Q:What is the difference between calcium silicate board and gypsum board?

- It is a high-quality high-grade cement as the base material, and with natural fiber reinforced, the advanced production process molding, pressure, high temperature steaming and other special technology and made, is a good performance of the new building and industrial Plate of its products fire, moisture, noise, insect moth, durable. Is the ceiling, cut off the ideal decorative plate.

- Q:Calcium silicate board in the water soak for a long time will become soft or other problems, the surface can be how long the colorful paint can fade or other problems

- Calcium silicate board is a waterproof product, soaked inside the water and then long will not be soft

- Q:Gypsum board with calcium silicate board which is good? What are the advantages and disadvantages?

- Gypsum board is a green building materials, a breathing function, suitable for interior decoration, upstairs that the sound insulation performance is not ideal, because the installation method has problems, not by the process to go, shortcomings impatient impact, can not be used for outdoor

- Q:Calcium silicate board ceiling of the joints with what will not crack it?

- Because you are in the construction of the time did not follow the requirements in the middle of the calcium silicate board to stay shrinkage 5mm, about it. Has been cracked place with a hand saw a gap, and then use calcium silicate board special sealing material seal, plus a joint belt and then on the seam material felt later on the paint

- Q:Jinfu calcium silicate board and Matsumoto easy hair board that kind of good?

- Different types of raw materials, different processes and different production processes processed calcium silicate board used in the range are also different, such as fiber reinforced calcium silicate board using a variety of conditions under the composite wall panels and lightweight partition board, especially for Composite walls of the interior and exterior panels, public buildings and civil buildings of the partition board, as well as ceiling, ceiling. Fiber reinforced calcium silicate board moisture resistance is better, it is also suitable for humid environments, such as bathrooms, kitchens, toilets and basement. At the same time, fiber reinforced calcium silicate board is also suitable for the activities of the ground, can be used for computer room, fire and moisture requirements of the Treasury and warehouses and so on. The calcium silicate board is used for the general houses and commercial ceiling, cut off more common place.

- Q:Decoration problem: a calcium silicate board about how many customers want me to calculate the weight. The Trouble trouble trouble.

- Calcium silicate board Solid raw material formula contains the following ingredients: cellulose fiber, quartz sand, dihydrate gypsum, wollastonite, lime, mica, cement. A dehydration reaction occurs during the hydrothermal process of the manufacturing process to obtain a light calcium silicate plate having a specific gravity in the range of 0.8 to 1.0 g / cm3.

- Q:Calcium silicate board surface putty Why crack?

- Usually in the board and board transfer place, very prone to cracking. And then the construction of such a transfer of the time, we must do anti-cracking treatment. If cracking has occurred, it will need to be shoveled along the cracks, and then fill with a dry coating, while the bandage to play a role in anti-cracking.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcium Silicate Insulation Block Sheet Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords