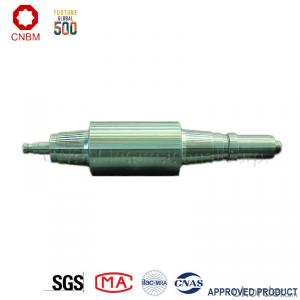

Alloy Roll with High Wear Resistance and High Performance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 41000 m.t./month

- Option:

- 650X1780X5540; 650X1780X5540; 680X2080X5920

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Company Profile

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM Group is integrated with four business segments: Manufacture, R&D,Sets of equipment and Logistics trading.Mill rolls are our main products.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 120 countries and regions all over the world.

The product introduction of mill roll

Equipped with advanced technological facilities on melting, casting, forging, heat treating and mechanical machining, our factory has formed 9 professional complete roll manufacturing lines of cast steel, cast iron and forged steel rolls such as strip mill rolls, heavy section mill rolls, wire & bar rolls, special shaped rolls and small-sized cold rolls and specialized production lines of bloom and slab CCM, coke oven equipments and wind power products. Annual production capacity of mill rolls is 500,000 tons, metallurgical equipment is 80,000 tons.

Workshop

Workshop is the core of our company and undertakes all of scientific research work. The company specially produces and supplies all kinds of roll used for hot strip mill, cold strip mill, plate & heavy plate mill, large-sized section mill, universal mill etc.

Products & Specification

Products & Specification

| Mill | Application | Material | Product Specification | ||

| Hot Strip Mill | Large-sized vertical roll | Special alloy cast roll, Adamite | All Sizes | ||

| Small-sized vertical roll | Adamite, HiCr iron | ||||

| Roughing work roll | Special alloy cast steel, Adamite, HiCr steel, Semi-HSS, HiCr iron | ||||

| Finish rolling | Early stand work roll | HiCr iron, HSS | |||

| Later stand work roll | ICDP, HSS | ||||

| Finishing back-up roll | Duplex cast steel | D≤¢2000,W≤80t | |||

| Alloy forged steel | D≤¢2000,W≤75t | ||||

| Temper rolling | Work roll | HiCr iron | All Sizes | ||

| Alloy forged steel | |||||

| Back-up roll | ICDP | ||||

| Duplex cast steel | D≤¢2000, W≤80t | ||||

| Alloy forged steel | D≤¢2000, W≤75t | ||||

| Mill | Application | Material | Product specification |

Cold strip mill & Single stand cold mill | Work roll | Alloy forged steel | All Sizes |

| Intermediate roll | Alloy forged steel | ||

| Temper roll | Alloy forged steel | ||

| Back-up roll | Duplex cast steel | D≤¢2000,W≤80t | |

| Alloy forged steel | D≤¢2000,W≤75t | ||

Largesized universal structural mill | Break-down roll | Special alloy cast steel, alloy nodular iron | All Sizes |

| Horizontal collar | High carbon adamite (duplex) | ||

| Vertical collar | High carbon adamite, HiCr iron | ||

| Edger roll Edger roll | High carbon adamite | ||

| Shaft | Alloy forged steel |

| Mill | Application | Marterial | Product Specification | |

| CSP | Vertical Roll | Adamite, Special alloy cast steel, HiCr iron | All Sizes | |

| Roughing work roll | Semi-HSS, HiCr Steel | |||

| Finish rolling | Early stand | HiCr iron, HSS | ||

| Later stand | ICDP, HSS | |||

| Roughing & Finishing back-up roll | Duplex cast steel | D≤¢2000,W≤80t | ||

| Alloy forged steel | D≤¢2000,W≤75t | |||

| Steckel Mill | Vertical roll | Adamite, Special alloy cast steel | All Sizes | |

| Roughing work roll | ICDP, HiCr iron | |||

| Finishing work roll | HiCr iron, ICDP | |||

| Back-up roll | Duplex cast steel | D≤¢2000,W≤80t | ||

| Alloy forged steel | D≤¢2000,W≤75t | |||

| Plate & Heavy plate mill | Rough rolling | 2-hi work roll | Special alloy cast steel, Tool steel | All Sizes |

| 4-hi work roll | HiCr iron, ICDP | |||

| Finishing work roll | HiCr iron, ICDP | |||

| Single stand work roll | HiCr iron, ICDP | |||

| Back-up roll | Duplex cast steel | D≤¢2000,W≤80t | ||

| Alloy forged steel | D≤¢2000,W≤75t | |||

Quality Control

The company has the most advanced experimental and testing equipments in global mill roll industry, including direct-reading spectrometer, spectrum analyzer , X-ray fluorescence analyzer, scanning electronic microscope, energy disperse spectroscopy, X-ray diffractometer, image analyzer, high/low temperature metallographic microscope, X-ray stress meter, brittleness temperature tester, thermal analogue machine, dilatometer, macro and micro hardness tester, OMNISCAM-1X automatic flaw detection, USN60 ultrasonic flaw detector, magnetic powder and non-destructive flaw detection etc,. The advanced inspection equipments and experimental methods provide guarantee for quality control and experiment on material, usability test and performance.

Professionals & Comprehensive Inspection

The factories of CNBM invested 2.3 billion RMB for large-scale

CNBM international Corporation has completed equipment and technology upgrade transformation, which was concentrated on three projects, production line of centrifugal casting rolls for hot strip and plate mill, forged roll for cold/hot strip mill, national class technology center and roll material lab. Through upgrade transformation, the following targets have been achideved:

(1)It becomes the world's biggest specialized mill roll maker with the largest production scale, the most complete specifications of products and the most extensive coverage of various rolls used on rolling mill.

(2) The technology of equipments has reached international leading level.

(3) "Mechanization, automation, intellectualization, digitization" of equipments obviously improve the quality control ability.

(4) New types of research instruments improve the R&D capacity of products.

Customers Visit

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your requirement.

- Q:How are pouring devices controlled in metal casting machinery?

- Metal casting machinery typically employs a blend of mechanical and automated systems to regulate pouring devices. The primary objective of these devices is to pour molten metal into molds during the casting process with precision and efficiency. One popular approach to managing pouring devices involves the use of mechanical valves or gates. These valves are operated manually, enabling the operator to open or close the flow of molten metal as required. This manual control grants the operator a certain degree of flexibility and accuracy in managing the pouring process. Nevertheless, with the advancement of technology, numerous metal casting machinery now incorporates automated systems to govern pouring devices. These automated systems employ sensors and actuators to ensure exact and consistent pouring of molten metal. For instance, sensors can be utilized to gauge the molten metal level in a crucible or furnace, prompting the pouring device to open when the desired level is attained. Additionally, automated pouring devices can be programmed to adhere to specific pouring patterns, guaranteeing precise and repeatable pouring of molten metal into molds. This programming can be accomplished through computer numerical control (CNC) systems, enabling precise regulation of pouring parameters such as speed and volume. Furthermore, certain metal casting machinery also leverage advanced technologies such as robotics to govern pouring devices. These robotic systems can be programmed to handle the entire pouring process, from ladling molten metal to pouring it into molds, without any human intervention. This not only enhances efficiency but also enhances safety by minimizing the risk of human error or exposure to hazardous conditions. In conclusion, pouring devices in metal casting machinery are controlled through a combination of mechanical valves, automated systems, and advanced technologies. These control methods ensure accurate, efficient, and consistent pouring of molten metal, resulting in top-notch castings.

- Q:How do you maintain and clean metal casting machinery?

- Maintaining and cleaning metal casting machinery is crucial for ensuring its optimal performance and prolonging its lifespan. Here are some steps to follow: Firstly, it is essential to regularly inspect the machinery for any signs of wear and tear, such as loose or damaged parts, leaks, or excessive vibrations. This can be done by trained personnel who are familiar with the equipment. To maintain the machinery, it is important to follow the manufacturer's guidelines and recommendations for maintenance schedules. This typically includes regular lubrication of moving parts, checking and adjusting belts, chains, and gears, as well as inspecting and cleaning filters, screens, and vents. Cleaning the machinery involves removing any built-up dirt, dust, or debris that may accumulate during operation. This can be done by using compressed air or vacuum cleaners to blow or suck away the contaminants. Care should be taken to avoid damaging any sensitive components during the cleaning process. Certain parts of the machinery may require specialized cleaning methods. For example, cooling systems may need to be flushed periodically to remove scale or sediment buildup. In such cases, it is advisable to refer to the manufacturer's instructions or consult with a professional technician to ensure the correct cleaning procedure is followed. Regularly inspecting and maintaining the electrical components of the machinery is also crucial for safety and efficient operation. This involves checking for loose connections, damaged wires, and worn-out insulation. If any issues are identified, it is important to address them promptly by consulting a qualified electrician. In addition to routine maintenance and cleaning, it is recommended to keep a record of all maintenance activities, such as dates of inspections, repairs, and replacements. This record can help identify any recurring issues or patterns, enabling proactive maintenance and minimizing downtime. Finally, it is important to train and educate the operators and maintenance personnel on proper cleaning and maintenance procedures. This includes emphasizing safety precautions, such as wearing appropriate personal protective equipment, and providing clear instructions on how to handle and store cleaning agents and lubricants. By following these steps and ensuring regular maintenance and cleaning, metal casting machinery can operate at its best, minimizing breakdowns, reducing downtime, and maximizing productivity.

- Q:What is the role of pouring equipment in metal casting machinery?

- The role of pouring equipment in metal casting machinery is to facilitate the controlled pouring of molten metal into molds. This equipment is designed to ensure a smooth and even flow of metal, allowing for consistent casting results. It helps to minimize the risk of defects such as air pockets, porosity, and uneven cooling. Pouring equipment typically consists of a ladle or crucible that holds the molten metal, a pouring system that controls the flow rate and direction, and various accessories like stoppers, sprue cups, and runners. The ladle or crucible is often equipped with a refractory lining to withstand the high temperatures of the molten metal. The pouring system is responsible for controlling the flow of molten metal from the ladle into the mold. This can be achieved through various mechanisms such as gravity pouring, tilting the ladle, or using automated pouring systems. The flow rate and direction are critical to ensure that the metal fills the mold cavity properly and avoids any potential defects. Additionally, pouring equipment may incorporate features like filtration systems or degassing mechanisms to remove impurities or gases from the molten metal before pouring. This helps in producing high-quality castings with improved mechanical properties. Overall, the pouring equipment plays a vital role in metal casting machinery by ensuring the controlled and precise pouring of molten metal into molds, which is essential for achieving accurate and defect-free castings.

- Q:What are the different types of coatings used with metal casting machinery?

- Metal casting machinery commonly utilizes various types of coatings. These coatings are applied to the die or mold surfaces to enhance casting quality and prolong mold lifespan. Some examples of coatings used in metal casting machinery are: 1. Refractory coatings: Made from materials like zircon, graphite, or alumina, these coatings create a protective layer on the mold surface. They prevent the molten metal from reacting with the mold material and reduce defects such as metal penetration, erosion, or sand burn-in. 2. Ceramic coatings: Usually composed of silica, alumina, or zirconia, ceramic coatings provide excellent heat resistance, thermal shock resistance, and high hardness. They improve casting surface finish, dimensional accuracy, and decrease defects like porosity or surface roughness. 3. Anti-stick coatings: These coatings, often made from boron nitride or graphite, prevent molten metal from sticking to the mold surface. They ensure easy release of the casting, minimizing the risk of damage or defects. 4. Release coatings: Used to facilitate easy casting removal, these coatings create a lubricating layer between the mold and casting, minimizing friction and preventing sticking. Silicone-based compounds or water-based emulsions are commonly used for release coatings. 5. Protective coatings: Applied to metal components of casting machinery, these coatings safeguard against corrosion, wear, or abrasion. They can be made from metallic alloys, polymer-based compounds, or ceramic materials. Protective coatings extend machinery lifespan and enhance performance. The choice of coating depends on factors such as the metal type, desired surface finish, casting complexity, and specific process requirements. Each coating type possesses unique properties and advantages. Selecting the appropriate coating is crucial for achieving high-quality castings and optimizing efficiency in metal casting machinery.

- Q:What are the different types of air pollution control measures used in metal casting machinery?

- Metal casting machinery commonly utilizes a variety of air pollution control measures to limit the release of harmful pollutants into the atmosphere, ensuring the well-being of workers and the environment. 1. Ventilation Systems: Installing ventilation systems is a fundamental control measure that effectively captures and removes dust, fumes, and gases produced during the casting process. These systems typically comprise exhaust hoods, ductwork, and fans that transport pollutants away from the workspace. 2. Filtration Systems: Vital for purifying the air, filtration systems employ filters to trap and collect particulate matter emitted during metal casting. Bag filters, cartridge filters, and electrostatic precipitators are frequently employed for this purpose. 3. Scrubbers: Scrubbers, air pollution control devices, eliminate harmful gases and volatile organic compounds (VOCs) from the exhaust stream. This is achieved by passing the contaminated air through a liquid solution or bed of materials that chemically reacts with and absorbs the pollutants. Wet scrubbers, dry scrubbers, and biofilters are commonly used scrubbing systems in metal casting machinery. 4. Emission Control Technologies: Sophisticated emission control technologies, such as catalytic converters and oxidation systems, are utilized in metal casting machinery to reduce the release of toxic substances like carbon monoxide (CO) and nitrogen oxides (NOx). These devices facilitate chemical reactions that convert harmful gases into less hazardous or inert compounds before being discharged into the atmosphere. 5. Process Modifications: Implementing process modifications can also aid in minimizing air pollution from metal casting machinery. Techniques such as adopting cleaner production methods, optimizing furnace design, and utilizing low-emission fuels significantly reduce the emission of pollutants during the casting process. It is important to note that the selection and effectiveness of air pollution control measures depend on various factors, such as the type of metal being cast, facility size, and specific pollutants emitted. Therefore, metal casting companies must regularly monitor emissions and conduct assessments to ensure the chosen control measures effectively reduce air pollution.

- Q:How does metal casting machinery reduce production costs?

- Metal casting machinery reduces production costs in several ways. Firstly, it allows for mass production, which means that large quantities of products can be produced at a significantly faster rate compared to manual casting methods. This increased production rate leads to economies of scale, where the cost per unit decreases as the volume of production increases. Secondly, metal casting machinery is highly automated, reducing the need for manual labor. This reduces labor costs, as fewer workers are required to operate and oversee the machinery. Additionally, automation improves efficiency and accuracy, minimizing errors and rework, thereby reducing costs associated with product defects. Furthermore, metal casting machinery enables the use of reusable molds, which significantly reduces material costs. Instead of creating new molds for each casting, these machines allow for the repeated use of molds, eliminating the need for continuous mold production. Moreover, metal casting machinery offers better control over the casting process, ensuring consistent quality and reducing the likelihood of product failure or rejection. This helps in minimizing the costs associated with scrap, rework, and customer returns. Additionally, modern metal casting machinery often incorporates advanced technologies like computer-aided design (CAD) and computer numerical control (CNC) systems. These technologies enhance precision, optimize material usage, and streamline the production process, resulting in cost savings. Overall, metal casting machinery reduces production costs by increasing production efficiency, reducing labor and material costs, improving product quality, and minimizing rework and waste. These cost-saving benefits make metal casting machinery a valuable investment for manufacturers in various industries.

- Q:How does metal casting machinery control the temperature and flow of the molten metal?

- Metal casting machinery controls the temperature and flow of the molten metal through various mechanisms and features. One of the key components is the furnace, which is responsible for heating the metal to its desired temperature. The furnace typically consists of a combustion chamber, burners, and a control system. The control system monitors and adjusts the fuel and air supply to maintain a consistent temperature within the furnace. Once the molten metal reaches the desired temperature, it is then transferred to a crucible or ladle, which acts as a reservoir for the molten metal. The crucible or ladle is equipped with heating elements or refractory materials to maintain the temperature of the molten metal during transfer and casting processes. To control the flow of the molten metal, metal casting machinery uses a variety of methods. One commonly used technique is gravity pouring, where the metal is poured into the mold using the force of gravity. In this case, the height and angle at which the crucible or ladle is positioned can be adjusted to control the flow rate. In more advanced systems, mechanical devices such as pumps or pouring robots are employed to control the flow of the molten metal. These devices are usually equipped with sensors and actuators that allow precise control over the speed and direction of the metal flow. The control system can regulate the flow rate based on the specific requirements of the casting process. Furthermore, temperature control during the casting process is crucial to ensure the quality and integrity of the final product. Metal casting machinery utilizes cooling systems, such as water-cooled molds or cooling channels, to regulate the temperature of the mold. This helps in solidifying the molten metal at the desired rate and preventing defects like shrinkage or porosity. In summary, metal casting machinery controls the temperature and flow of the molten metal through various mechanisms like heating systems, gravity pouring, mechanical devices, and cooling systems. These features work together to achieve precise and consistent control over the casting process, resulting in high-quality metal castings.

- Q:Can metal casting machinery be used for investment casting of ceramics?

- Using metal casting machinery for investment casting of ceramics is not possible. Metal casting machinery is designed for melting and pouring molten metals into molds to create metal parts. This process involves high temperatures and pressures which are suitable for metals, but not for ceramics. On the other hand, investment casting of ceramics requires a different set of equipment and techniques. It involves the creation of a mold around a wax pattern, followed by the removal of the wax to create a cavity. The ceramic slurry is then poured into the cavity and allowed to solidify. Once the ceramic part is fully cured, the mold is broken to retrieve the final product. Since ceramic investment casting requires specialized machinery that can handle the delicate nature of ceramics, as well as the specific temperature and pressure conditions necessary for the process, it is not feasible to utilize metal casting machinery for investment casting of ceramics.

- Q:How is the shape of the final product determined in metal casting machinery?

- Several factors determine the shape of the final product in metal casting machinery. The design and shape of the mold play a crucial role in shaping the end product. Typically, the mold is made from materials like sand, plaster, or metal and is created to replicate the desired shape of the final product. The molten metal is then poured into the mold, solidifying and taking the shape of the mold. The process of filling the mold with molten metal is also significant in determining the shape of the final product. Usually, the metal is poured into a sprue, a channel leading to the mold cavity. As the metal flows through the sprue, it fills the mold cavity, acquiring the shape of the mold as it solidifies. The shape of the final product is also influenced by the temperature and cooling process. The molten metal must be heated to a specific temperature to ensure smooth flow and complete filling of the mold. The cooling process is equally crucial as it allows the metal to solidify and retain the mold's shape. Controlling the cooling rate is necessary to prevent any deformities or imperfections in the final product. Moreover, the type of metal used can also impact the shape of the final product. Different metals possess varying properties, including melting points and shrinkage rates, which affect how the metal fills the mold and solidifies. Some metals may require additional steps, like preheating or pre-cooling, to achieve the desired shape. In conclusion, the shape of the final product in metal casting machinery is determined by the mold's design, the process of filling the mold with molten metal, the temperature and cooling process, and the properties of the metal used. By carefully controlling these factors, manufacturers can produce metal castings with precise and accurate shapes.

- Q:Can metal casting machinery be used for producing castings with good machinability?

- Yes, metal casting machinery can be used for producing castings with good machinability. The machinability of a casting depends on various factors such as the type of metal being cast, the casting process used, and the design of the casting. With proper control over these factors, metal casting machinery can produce castings that are suitable for machining operations, resulting in good machinability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alloy Roll with High Wear Resistance and High Performance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 41000 m.t./month

- Option:

- 650X1780X5540; 650X1780X5540; 680X2080X5920

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches