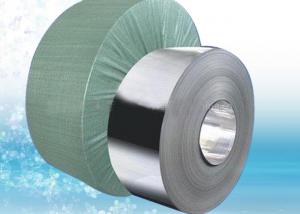

201 2B Stainless Steel Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

201 2B Stainless Steel Strips

1. Chemical composition of 201 2B Stainless Steel Strips

C | Si | Mn | P | S | Ni | Cr |

max0.15 | max1.00 | 5.50-7.50 | max0.06 | max0.03 | max1.00 | 16.00-18.00 |

2. Mechanical properties of 201 2B Stainless Steel Strips

Yield Strength | Tensile | Elongation | Hardness (HV) | Hardness (HRB) |

245 | 640 | 40 | 253 | 100 |

3. Standard:

AISI, ASTM, GB, EN, DIN, JIS

4. Surface:

2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size:

Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms:T/T or L/C

8. Packing:

Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time:

Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q:Can stainless steel wire be used for safety wire applications?

- Yes, stainless steel wire can be used for safety wire applications. Stainless steel wire is known for its strength, durability, and resistance to corrosion, making it suitable for various safety-related applications. Safety wire is commonly used to secure fasteners, prevent loosening or vibration, or to provide an additional level of safety in critical systems. Stainless steel wire, with its high tensile strength and resistance to rust and corrosion, is well-suited for these purposes. It offers excellent performance in harsh environments, making it a reliable choice for safety wire applications in industries such as aerospace, automotive, and manufacturing.

- Q:What are the common uses of stainless steel wire in the aerospace industry?

- Stainless steel wire is commonly used in the aerospace industry for a variety of applications. It is primarily used for structural purposes, such as reinforcing aircraft frames, manufacturing support structures, and forming cables for suspension systems. Additionally, stainless steel wire is used in the fabrication of engine components, electrical wiring, and fuel line systems due to its high strength, corrosion resistance, and excellent heat resistance properties.

- Q:What are the different sizes and diameters available for stainless steel wire?

- The sizes and diameters available for stainless steel wire vary widely depending on the specific application and industry requirements. Stainless steel wire can be found in a range of diameters starting from as small as 0.001 inch (0.0254 mm) and going up to larger sizes like 0.500 inch (12.7 mm) or even bigger. The different sizes and diameters allow stainless steel wire to be used in various applications such as jewelry making, medical equipment, construction, and industrial manufacturing.

- Q:How are stainless steel wire ropes used in sailing?

- Various purposes in sailing are served by stainless steel wire ropes, which are an essential component. Mainly utilized for rigging applications on sailboats, they offer strength, durability, and resistance to corrosion in the harsh marine environment. Standing rigging is one of the primary uses of stainless steel wire ropes in sailing. It refers to the fixed wires and cables that support the mast, ensuring stability and preventing collapse under the force of the wind. Due to their high tensile strength, stainless steel wire ropes are well-suited for this purpose, as they can withstand the tremendous loads experienced during sailing. In addition, stainless steel wire ropes are also used for running rigging, which involves movable ropes used to control the sails and maneuver the boat. These ropes must be flexible and reliable, as they are constantly under tension, bending, and abrasion. Stainless steel wire ropes provide the necessary strength and flexibility to handle these dynamic loads while maintaining their integrity. Furthermore, stainless steel wire ropes find application in various other areas on sailboats. They are commonly used in lifelines, which are horizontal ropes running around the boat's perimeter, providing safety and preventing crew members from falling overboard. These lifelines need to be strong and corrosion-resistant, making stainless steel wire ropes the ideal choice. Stainless steel wire ropes are also utilized in halyards, which are ropes used to raise and lower sails. Halyards require a combination of strength and flexibility to handle the weight of the sails and withstand constant movement. Stainless steel wire ropes meet these requirements, ensuring smooth and reliable sail adjustments. Overall, stainless steel wire ropes play a crucial role in sailing by providing the necessary strength, durability, and resistance to corrosion required for the rigging systems on sailboats. Whether for standing rigging, running rigging, lifelines, or halyards, stainless steel wire ropes are an integral part of a sailboat's equipment, contributing to its performance, safety, and longevity.

- Q:What are the different wire tensile strength measurement methods for stainless steel wire?

- There exist several techniques for measuring the tensile strength of stainless steel wire. These techniques encompass: 1. Tensile Testing: This method, commonly employed, assesses the tensile strength by incrementally increasing the force applied until the wire fails. The force required to cause failure is then recorded and utilized to calculate the wire's tensile strength. 2. Stress-Strain Curve: In this approach, the stress and strain of the wire are gauged as it experiences progressively greater forces. The resultant stress-strain curve aids in determining the maximum load the wire can sustain prior to failure, thereby indicating its tensile strength. 3. Microhardness Testing: This technique entails employing a microhardness tester to measure the hardness of the wire's surface. By correlating the hardness value with established relationships, the wire's tensile strength can be inferred. 4. X-Ray Diffraction: By utilizing X-ray diffraction, this method quantifies the lattice strain present within the crystal structure of the wire. Through analysis of the lattice strain, the wire's tensile strength can be ascertained. 5. Non-Destructive Testing: This technique leverages non-destructive methods like ultrasonic testing or magnetic particle inspection to evaluate the wire's tensile strength. Such methods are capable of identifying defects or irregularities in the wire that may impact its strength. It is worth noting that each method possesses its own set of advantages and limitations. The choice of method relies on various factors, including the specific requirements of the application, the dimensions and shape of the wire, and the available resources.

- Q:Can stainless steel wire be used for filtration purposes?

- Indeed, filtration purposes can indeed utilize stainless steel wire. Renowned for its corrosion resistance, durability, and strength, stainless steel proves itself as the perfect material for filtration applications. It can be skillfully woven into an assortment of mesh sizes and shapes to meet diverse filtration needs. Industries such as food processing, chemical, pharmaceutical, and water treatment frequently employ stainless steel wire mesh to effectively separate impurities, debris, and contaminants while permitting the desired substances to pass through. Furthermore, stainless steel wire mesh boasts the ability to endure elevated temperatures and harsh environments, thus establishing itself as a dependable option for filtration purposes.

- Q:What are the different corrosion resistance levels of stainless steel wire?

- Stainless steel wire has different corrosion resistance levels depending on the specific grade and composition of the alloy. Generally, stainless steel wire can be classified into three main corrosion resistance levels: low, medium, and high. The low corrosion resistance level is typically associated with 400 series stainless steel, which contains less chromium and is more prone to corrosion in certain environments. The medium corrosion resistance level is found in 300 series stainless steel, which has a higher chromium content and offers better resistance to corrosion in many applications. The high corrosion resistance level is often attributed to specialized alloys such as 316 stainless steel, which contains additional elements like molybdenum, providing excellent resistance to corrosive agents such as acids and chloride solutions.

- Q:Why are the 304 stainless steel wires magnetic? And the thinner the wire, the greater the magnetism

- In addition, 304 stainless steel after cold processing, the structure of the structure will also change to martensite, and the greater the deformation degree of cold work, the more martensite transformation, the greater the magnetism. Like a lot of stainless steel wire, made straight, no obvious induction, but it is bent into a rectangular or circular, and produce some magnetic for cold bending deformation is large, especially the angle of magnetic is more obvious.

- Q:What are the common applications of stainless steel wire?

- Stainless steel wire has a wide range of applications due to its unique properties. It is commonly used in industries such as construction, automotive, aerospace, and electronics. Some common applications include wire mesh for filtration and sieving purposes, reinforcement in concrete structures, fencing and security barriers, electrical wiring, and cable ropes. Additionally, stainless steel wire is used in medical devices, kitchen utensils, and jewelry, thanks to its corrosion resistance and aesthetic appeal.

- Q:Is stainless steel wire suitable for wire rope saddles?

- Yes, stainless steel wire is suitable for wire rope saddles. Stainless steel wire has excellent corrosion resistance and high strength, making it a reliable choice for wire rope saddles that need to withstand heavy loads and harsh environments.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang, China |

| Year Established | 2005 |

| Annual Output Value | Above US$1.6 million |

| Main Markets | Europe, North America. |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40% |

| No.of Employees in Trade Department | Above 30 people |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | Above 5000 square meter |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

201 2B Stainless Steel Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords