Stainless Steel Square Tube

Stainless Steel Square Tube Related Searches

Best Paint For Stainless Steel Paint For Galvanized Steel Steel Frames For Furniture Self Tapping Screws For Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For Bbq Step Bit For Stainless Steel Sponge For Stainless SteelHot Searches

Aluminum Square Stock For Sale Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale White Gazebo For Sale White Melamine Board Price Frp Price Per Square Foot Ceiling Fan Lowest Price Plywood Per Square Foot Price Cost Of Plywood Per Square Metre Aluminum Square Stock Near Me Cost Of Mdf Per Square Metre White Plastic Folding Chairs Wholesale Geotextile Fabric Cost Per Square Foot Frp Cost Per Square Foot Plywood Cost Per Square Meter Asphalt Shingle Prices Per Square Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless SteelStainless Steel Square Tube Supplier & Manufacturer from China

Okorder.com is a professional Stainless Steel Square Tube supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Stainless Steel Square Tube firm in China.Hot Products

FAQ

- Indeed, gas transportation can indeed make use of stainless steel pipes. Stainless steel, known for its resistance to corrosion, possesses the ability to endure high-pressure circumstances. This characteristic makes it suitable for the conveyance of diverse gases such as natural gas, propane, and hydrogen. The strength, durability, and ability to withstand extreme temperatures exhibited by stainless steel pipes render them an unquestionably dependable choice for gas transportation. Moreover, the non-reactive nature of stainless steel guarantees the preservation of gas integrity and reduces the likelihood of contamination. All in all, the gas industry extensively employs stainless steel pipes due to their reliable nature, safety, and prolonged lifespan.

- The main difference between 304J6 and 316J6 stainless steel pipes lies in their composition and properties. 304J6 stainless steel is a low carbon variation of the popular 304 stainless steel. It contains around 18% chromium and 8% nickel, which provides excellent corrosion resistance and durability. This grade is commonly used in various applications, including food processing, chemical processing, and architectural purposes. On the other hand, 316J6 stainless steel is an austenitic stainless steel grade known for its higher corrosion resistance compared to 304J6. It contains around 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The addition of molybdenum enhances its resistance to pitting and crevice corrosion in chloride environments, making it suitable for marine and coastal applications. In terms of mechanical properties, both grades offer good strength and toughness. However, 316J6 stainless steel typically has higher tensile strength and hardness due to its alloy composition. When it comes to price, 316J6 stainless steel pipes are generally more expensive than 304J6 due to the higher cost of molybdenum. Therefore, the choice between the two grades depends on the specific requirements of the application and the level of corrosion resistance needed.

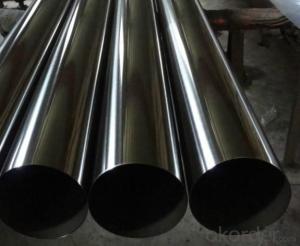

- Yes, stainless steel pipes can be mirror polished. Mirror polishing is a process that involves grinding down the surface of the stainless steel pipe until it is smooth and then using a series of polishing compounds to achieve a high gloss finish. This process can be done by hand or with the use of specialized machinery. The mirror polished finish not only enhances the aesthetic appeal of the stainless steel pipe but also provides added protection against corrosion and staining. However, it is important to note that the mirror polished finish may require regular maintenance to maintain its shine over time.

- Yes, stainless steel pipes are suitable for high-pressure steam applications. Stainless steel has excellent corrosion resistance, high-temperature strength, and durability, making it a suitable material choice for handling high-pressure steam.

- Stainless steel pipes are made through a process called stainless steel pipe manufacturing. This process involves several steps to ensure the production of high-quality pipes that are durable, corrosion-resistant, and suitable for various applications. Firstly, the raw material, which is stainless steel, is selected based on its composition and desired properties such as strength, corrosion resistance, and heat resistance. Stainless steel is an alloy made primarily of iron, chromium, and other elements like nickel and molybdenum. Once the stainless steel is obtained, it goes through a melting process in an electric furnace, where the steel is melted at extremely high temperatures. This molten steel is then poured into molds to form billets or ingots, which are solidified and shaped into cylindrical bars. The next step is to heat the billets or ingots in a furnace to a specific temperature range to make them more malleable. This process is called hot rolling, and it involves passing the heated billets through a series of rollers to reduce their diameter and thickness. This continuous rolling process helps to refine the stainless steel's grain structure and improve its mechanical properties. After hot rolling, the stainless steel is annealed, which involves heating the material to a specific temperature and then gradually cooling it. Annealing helps to relieve any internal stresses in the steel caused by the hot rolling process and enhances its ductility and toughness. The annealed stainless steel is then subjected to cold rolling, where it is passed through a series of rollers at room temperature. Cold rolling further reduces the diameter and thickness of the stainless steel, resulting in a smoother surface finish and tighter tolerances. Once the desired dimensions are achieved, the stainless steel undergoes a process called welding or seamless pipe manufacturing, depending on the type of pipe being produced. In the case of welded stainless steel pipes, the cold-rolled stainless steel strip is formed into a cylindrical shape and then welded longitudinally using various welding techniques such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. This welding process ensures the integrity and strength of the pipe. On the other hand, seamless stainless steel pipes are made by piercing a solid cylindrical billet or ingot to form a hollow tube. This is achieved through a process called piercing, where a mandrel is used to create a cavity in the billet. The pierced billet is then elongated and rolled to the desired length and diameter. After the pipes are formed, they undergo various finishing processes such as heat treatment, pickling, passivation, and polishing to enhance their corrosion resistance, remove any surface impurities, and improve their aesthetic appearance. In conclusion, stainless steel pipes are made through a combination of melting, hot rolling, annealing, cold rolling, welding or seamless pipe manufacturing, and various finishing processes. This meticulous production process ensures the production of high-quality stainless steel pipes that meet the required specifications and standards.

- Yes, stainless steel pipes can be used for architectural sculptures. Stainless steel is known for its durability, resistance to corrosion, and ability to withstand various weather conditions, making it a suitable material for outdoor sculptures. Its sleek and modern appearance also adds an aesthetic appeal to architectural designs.

- Yes, stainless steel pipes can be coated or painted. Coating or painting stainless steel pipes can provide various benefits such as enhanced corrosion resistance, improved aesthetic appearance, and increased durability. However, it is important to note that proper surface preparation is crucial before applying any coating or paint to ensure adhesion and longevity. Additionally, it is recommended to use coatings or paints specifically designed for stainless steel to maintain its inherent qualities and prevent any potential issues such as flaking or peeling.

- The main difference between seamless and hot-rolled stainless steel pipes lies in their manufacturing processes. Seamless stainless steel pipes are produced through a method called extrusion, where a solid billet is heated and forced through a die to create the desired pipe shape. This process ensures a smooth and uniform surface finish, without any welded joints. On the other hand, hot-rolled stainless steel pipes are made by heating a metal billet and then rolling it into the desired shape. This method often results in a rougher surface finish and may require additional processes such as welding to join multiple segments. Overall, seamless pipes tend to have higher strength and corrosion resistance due to their uniform composition and lack of welds, making them suitable for applications with high pressure or corrosive environments. Hot-rolled pipes, while more cost-effective, may have limited use in certain demanding conditions.