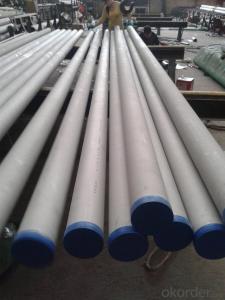

Stainless Steel Distributor

Stainless Steel Distributor Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For SaleStainless Steel Distributor Supplier & Manufacturer from China

Okorder.com is a professional Stainless Steel Distributor supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Stainless Steel Distributor firm in China.Hot Products

FAQ

- Yes, plastic tubes can be used for promotional or sample packaging. They are versatile, cost-effective, and offer a convenient way to package and showcase products or samples. Plastic tubes can be customized with branding and graphics, making them an attractive option for promotional purposes. Additionally, their durability and ability to protect the contents make them suitable for sample packaging as well.

- I have a little bit of a project. I'm trying to figure a way to cool a pair of water filled tubing lines. I was thinking to wrap it with some type of cooling device but not quite sure what to use. Can you guys give me some ideas? I want to cool the lines as cool as refrigerator temps. Thanks.

- You have not said how much heat you need to disperse - whether it needs to be a continuous process or not. You have not mentioned whether the lines are flexible or what length they are! However, without making things too complicated, if you use a longish length of plastic tubing, you could coil them and run them through a bucket full of an ice/salt/water mixture. Depending on how fast the water is moving through the tubes, if you had a strong mixture of salt and ice - with just enough water in the bucket to allow conduction - you might be able to freeze the water in the tubes - which is probably NOT what you want to do. So experiment before the performance.

- What is the thermal fuse sleeve of the wire mesh plastic composite pipe?

- Quota refers to the quantity standard of manpower, material resources, financial resources and time consumed by qualified units under certain technical and organizational conditions. In the labor organization reasonable and rational use of materials and machinery under the condition of a predetermined number of resources consumed by the completed units qualified product standards, the level of social productive forces, it reflects the level of a certain period of time.

- I'm building a computer and I got to the liquid cooling option and I can't decide between copper tubing and plastic tubing. I've seen plastic tubing and know that plastic is easier to detach, but I think copper might cool the components better. Any suggestions?(Note-this is not a budget build by any means-I want to know which one performs better, not what's the best bang for your buck)

- Copper is better bang but needs to be bent for each component. Plastic is flexible and just needs to be cut to length

- Is there an easy way to remember the color tubes (phlebotomy) and what test they are needed for?

- Yes, okorder /

- The common wall thicknesses for plastic tubes vary depending on their intended use and the specific industry. However, some typical ranges for plastic tube wall thicknesses include 0.5mm to 3mm for general-purpose applications, while thicker tubes ranging from 3mm to 6mm or more are often used for structural or heavy-duty applications.

- No, plastic tubes are not typically resistant to freezing temperatures as they can become brittle and crack when exposed to extreme cold.

- Do not pipe plastic pipe connection

- Buy a metal. With the elbow sealing machine and plastic pipe connected together by threads in the two ends and two pipes on the line.