Socket Programming Tutorial

Socket Programming Tutorial Related Searches

Cast Aluminum Chaise Lounge With Wheels Plastic Storage Tubes With Caps Ge Dehumidifier With Pump Gas Furnace With Ac Teal Accent Chair With Arms Nightstand Lamp With Usb Driveway Pillars With Lights Cr2330 Battery With Tabs Classroom Chairs With Wheels Bathrooms With Vessel SinksHot Searches

Mini Inverter With Battery Online Shopping ppr pipe manufacturers in saudi arabia ppr pipes price list philippines ppr type 3 Food Mixer Sale Ex Display Log Cabins For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For Sale Buy Limestone For Carving Buy Alabaster For Carving Pedestal Fan With Water Spray Price High Mast Light Price List Solar High Mast Light Specification Mini Inverter With Battery Online Shopping Philips High Mast Lighting Price List Bajaj High Mast Lighting Price List High Mast Light Specification Stainless Steel Supply Near MeSocket Programming Tutorial Supplier & Manufacturer from China

Okorder.com is a professional Socket Programming Tutorial supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Socket Programming Tutorial firm in China.Hot Products

FAQ

- The average lifespan of plastic pipe fittings can vary depending on various factors such as the type of plastic used, the quality of manufacturing, and the conditions in which they are installed and used. However, on average, plastic pipe fittings can last anywhere from 20 to 50 years.

- Yes, plastic pipe fittings are generally resistant to impact and pressure. They are designed to withstand the forces exerted on them during normal operating conditions, ensuring durability and reliability in various applications. However, the specific resistance may vary depending on the type and quality of the plastic used in the fittings.

- Yes, plastic pipe fittings are generally resistant to pressure. However, the level of pressure resistance can vary depending on the type and quality of the plastic material used in the fittings. It is important to choose fittings that are suitable for the specific pressure requirements of the plumbing system to ensure optimal performance and durability.

- No, plastic pipe fittings are not suitable for all types of pipes. They are typically designed to work with specific types of pipes, such as PVC or CPVC pipes. Different types of pipes may require different materials and fittings for proper installation and performance.

- Plastic pipe fittings can vary in their resistance to ground settlement depending on the specific material and design. However, generally speaking, plastic pipe fittings are less rigid compared to metal fittings, which can make them more prone to movement and displacement in the event of ground settlement. It is important to consider factors such as the type of plastic used, the depth of the pipe installation, and the soil conditions when determining the overall resistance to ground settlement.

- Yes, plastic pipe fittings can be used for underground irrigation systems. Plastic pipe fittings are commonly used in these systems due to their durability, resistance to corrosion, and cost-effectiveness. They are also lightweight and easy to install, making them a popular choice for underground irrigation systems.

- Plastic pipe fittings have the ability to handle thermal expansion and contraction quite well. Due to the nature of plastic materials, they have a higher coefficient of thermal expansion compared to metals. This means that when exposed to heat, plastic fittings will expand more than metal fittings. However, plastic pipe fittings are designed with certain features such as flexibility and elasticity to accommodate the thermal expansion and contraction. These fittings can absorb the expansion and contraction without causing any damage or leakage in the piping system. Additionally, the use of expansion joints or loops in the piping system helps to further compensate for the thermal changes, ensuring the integrity and durability of the plastic pipe fittings.

- What is the difference between plastic pipe fittings and hot melt plastic water supply pipe fittings?

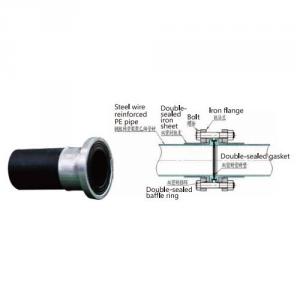

- As the name suggests is lining plastic pipe in the pipe wall lining a layer of plastic, for the purpose of internal corrosion of steel pipe, but as a senior sales staff, the deaf ears furnishings still can be divided clearly, pipe lined with plastic for wire, tube wall has plastic layer, but the pipe with a connection, the inner wall of the pipe the plastic layer and the middle layer plastic pipe wall cracks can not reach the requirement of water resistance, a long time will cause the plastic layer and the steel layer from the water can not circulate time wall middle long will breed bacteria instead of water pollution.