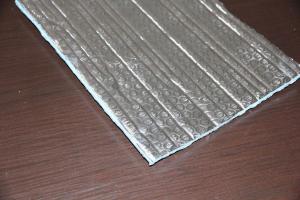

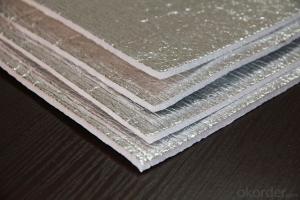

Roof Insulation Materials

Roof Insulation Materials Related Searches

Led Light Bulbs For Ceiling Fixtures Decorative Ceiling Plate For Light Fixture Ceiling Plate For Hanging Light Fiberglass Panels For Roofing Heat Reflective Material For Roof Track Lights For Kitchen Ceiling Lights For Kitchen Ceiling Lights For Fall Ceiling Hanging Ceiling Chairs For Bedrooms 42 White Ceiling Fan With LightHot Searches

Used Foam Board Insulation For Sale Fiberglass Scaffolding For Sale Plastic Roof Tiles For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Roxul Insulation For Sale Polyurethane Insulation Board Price Polyisocyanurate Rigid Foam Insulation Price Cost Of Concrete Tile Roof Styrofoam Insulation Sheets Price Roof Insulation Price Multi Layer Insulation Price Artificial Slate Roof Tiles Price Polystyrene Insulation Price Ceiling Fan Lowest Price Tesla Solar Roof Inverter Types Of Flat Roof Coverings Company Office Design Ceramic Roof Tiles Cost Metal Roof Tiles PricesRoof Insulation Materials Supplier & Manufacturer from China

Okorder.com is a professional Roof Insulation Materials supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Roof Insulation Materials firm in China.Hot Products

FAQ

- nan

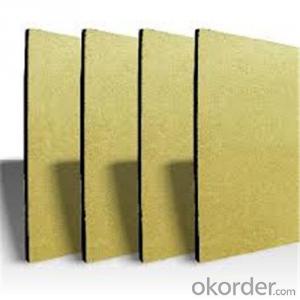

- Centrifugal glass wool board is board product with a certain intensity which is made by curing centrifugal glass wool. Whether in high or low temperature environment, it can maintain good heat insulation and sound absorption properties, mainly used for interior wall compartment in advanced architecture, compartment, ceiling, heat conservation for iron sheet air duct or aie bellow, sound absorption and noise reduction for studio, machine room and other places.

- nan

- They are from twenty to less than eighty.

- Glass wool can be used at zero degrees

- There are alkali superfine glass wool felt temperature: -100 ~ 450 ℃

- nan

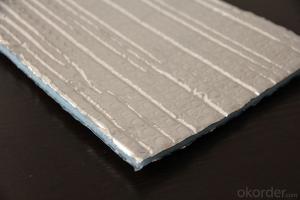

- Glass wool can only be used in about 260℃, but the highest operating temperature of rock wool is about 600℃. It is easy to construct and install, and can be used for many years with good effect of energy conservation, suitable for small storage tanks and cambered surface with small surface curvature radius and equipments with irregular surface. Rock wool has low heat conductivity coefficient, usually used in thermal insulation places at 450℃. Glass wool has lighter unit weight, lower shot content and higher cost performance ratio than rock wool, so it is widely used in insulation of general buildings and low temperature pipes, building air condition piping insulation and wall sound absorption. While rock wool felt is a quality thermal insulation material with low heat conductivity coefficient. Rock wool felt, with excellent insulation property and low price, is widely used in insulation for high temperature heat pipelines or electrical equipments. While glass wool is usually used in insulation places under 200℃。 Suitable for pipes with medium and large diameter. Fiber has strong toughness. That depends on your need.

- nan

- This is not necessary, it depends on the place the shell is used, the best thing is to add a layer of insulation tape.

- nan

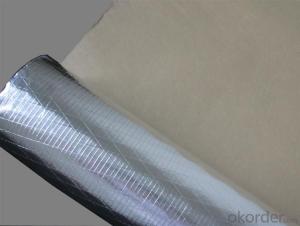

- Centrifugal glass wool felt, steel glass wool felt, roof dedicated centrifugal glass wool felt,aluminum foil glass wool blankets centrifugal glass wool felt. glass wool is added with binding agent and cured under high temperature into panniform. Its bulk density is lighter than panel,good elasticity, cheap and easy construction. Centrifugal glass wool felt major technical indicators: Centrifugal glass wool felt Bulk density: (Kg / m3) 14,16,20,24,32,48 centrifugal glass wool felt Thermal conductivity coefficiency. 0.038w / m.h. ℃ centrifugal glass wool felt Size: Width 1200mm, length 11mm 22mm (negotiable) centrifugal glass wool felt thickness: 25-150mm (negotiable) centrifugal glass wool felt Uses: fireproofing, thermal insulation, sound absorption for high-rise buildings and refrigeration. Thermal and cold insualtion of air-conditioned rooms, vehicles, ships.

- nan

- If you want to be simple, use sound barrier mats. If you want to be a completely soundproof environment, use sound absorption materials. If you use glass wool, you have to be aware of skin and respiratory tract infection.

- nan

- Glass wool is one kind of the glass fiber and it is a man-made inorganic fiber. Glass is made by melting such raw materials as quartz sand, limestone, dolomite and other natural ore with some chemical materials like pure alkali and sodium borate. In the molten state, the glass is thrown into fine fibers in the shape of floc by the with external force. These fibres vertically interwine and show many small gaps. These gaps can be regarded as air void. Thus, glass wool can be regarded as porous materials and it is of good insulation and sound absorption performance.