Geomembrane Fabric

Geomembrane Fabric Related Searches

Geomembrane For Landfill Geomembrane In Hdpe Geomembrane In Pakistan Pvc Geomembrane Liner Pvc Geomembrane Institute Hdpe Geomembrane Machine Geomembrane Machine Plastic Geomembrane Hdpe Geomembrane Self Adhesive Geomembrane CoverHot Searches

Tilt Panel Props For Sale Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Glass Wool Manufacturers In India Mineral Wool Insulation Price List Glass Wool Price List Glass Wool Price India Solar Panel Inverter Suppliers Q Cells Solar Panel Prices Tesla Solar Panel Inverter Geogrid Fabric Price Ceiling Fan Lowest Price Eps Panel Cost Geogrid Fabric Home Depot Geotextile Fabric Cost Per Square Foot Geotextile Filter Fabric Prices Geotextile Filter Fabric Specification Geogrid Fabric PriceGeomembrane Fabric Supplier & Manufacturer from China

Okorder.com is a professional Geomembrane Fabric supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geomembrane Fabric firm in China.Hot Products

FAQ

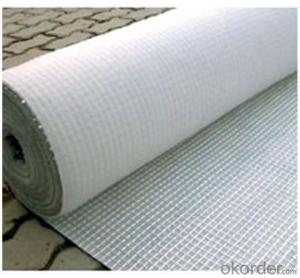

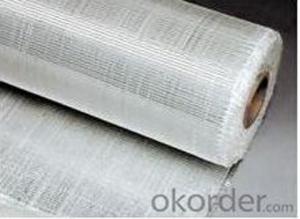

- There are several types of geomembranes, including high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC), ethylene propylene diene monomer (EPDM), and chlorosulfonated polyethylene (CSPE).

- Geomembranes contribute to energy production projects by providing a reliable and cost-effective solution for containing and managing liquids and waste materials. They are used in various applications, such as lining reservoirs, ponds, and landfills, to prevent leakage and seepage of fluids. This ensures the efficient storage and transportation of resources, such as water, oil, and gas, which are essential for energy production. Additionally, geomembranes help in the construction of sustainable energy infrastructure, such as solar farms and wind turbine foundations, by providing a protective barrier against soil erosion and groundwater contamination. Overall, geomembranes play a vital role in enhancing the safety, efficiency, and environmental sustainability of energy production projects.

- nan

- 1. Ultrasonic thickness gauge Hong Kong Teichman TM1402. Taiwan Baker Royce paint film thickness gauge BK-8113A film thickness of iron-based coating thickness gauge 3. Lanteri coating thickness CM8822 non iron-based coating thickness gauge 4.LYT -2008 using magnetism thickness measurement method

- nan

- How is the metal plating ceramic film? in the preparation process, it is very important not to damage the coating while conducting treatment carefully of the surface layer. And because this film is made of silicon oxide, the surface has excellent wettability. therefore, it is compatible with any printing ink and adhesives. So overall quality is very good.

- nan

- As a new material, geomembrane has excellent anti-seepage effect, corrosion resistance and chemical stability. And it can process features and functionality according to the actual project needs. Geomembrane has been widely used in water conservancy embankment dam , reservoir seepage. At the same time, it has ben widely used as seepage-proof, anti-corrosion, leakage-proof and non-hygroscopic material in channel, impounding reservoir, cesspit, swimming pool, house building, underground structure, wasteyard, environmental engineering, etc.

- Geomembranes contribute to the protection of buried pipelines by acting as a barrier between the pipeline and the surrounding soil or environment. They provide a protective layer that helps prevent corrosion, abrasion, and damage from external factors such as chemicals, moisture, and root penetration. Additionally, geomembranes can enhance the overall structural integrity of the pipeline by distributing external loads and reducing the risk of settlement or deformation.

- Geomembranes are designed to withstand temperature variations through their unique composition and structure. They are made from materials that have a high resistance to temperature changes, such as polyethylene or polyvinyl chloride (PVC). These materials have excellent thermal stability, allowing them to remain durable and flexible across a wide range of temperatures. Additionally, geomembranes are often reinforced with additives and reinforcements that further enhance their ability to withstand temperature fluctuations. This combination of materials and reinforcements enables geomembranes to maintain their integrity and functionality even in extreme hot or cold conditions.