Agru Geomembrane

Agru Geomembrane Related Searches

Blu Ray Player With Internet Geomembrane In Pakistan 30 Mil Pvc Geomembrane Pvc Geomembrane Specifications Pvc Geomembrane Geomembrane Machine Plastic Geomembrane Nonwoven Wallpaper Geomembrane Material Geomembrane FabricHot Searches

Geomembrane For Sale China Pvc Geomembrane China Geomembrane Roll Sheet Hdpe Geomembrane Sheet Price Hdpe Geomembrane China China Geomembrane Geomembrane China Hdpe Geomembrane Price Geomembrane Price Wholesale Hdpe Geomembrane Roll Geomembrane Factory Wholesale Liner Hdpe Geomembrane Wholesale Geomembrane Hdpe Wholesale Hdpe Geomembrane Geomembrane Market Size Wholesale Hdpe Geomembrana Wholesale Liner Geomembrane Geomembrane Liner Supplier Wholesale Geomembrane China Pvc GeomembraneAgru Geomembrane Supplier & Manufacturer from China

Okorder.com is a professional Agru Geomembrane supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Agru Geomembrane firm in China.Hot Products

FAQ

- Geomembranes prevent water seepage in storage tanks by providing a barrier between the stored liquid and the surrounding soil or environment. These impermeable liners are carefully installed to ensure a tight seal, preventing any leakage or seepage of water. Additionally, geomembranes are highly resistant to punctures, tears, and chemical degradation, further enhancing their effectiveness in preventing water seepage in storage tanks.

- There are several advantages to using geomembranes in roof waterproofing. Firstly, geomembranes are highly resistant to water and moisture, effectively preventing leaks and water damage. Secondly, they are also resistant to UV rays, which means they can withstand prolonged exposure to sunlight without deteriorating. Additionally, geomembranes are flexible and can be easily installed on roofs of different shapes and sizes. They also have a long lifespan and require minimal maintenance, making them a cost-effective solution for roof waterproofing. Finally, geomembranes are environmentally friendly as they are made from recyclable materials and do not release harmful chemicals into the environment.

- nan

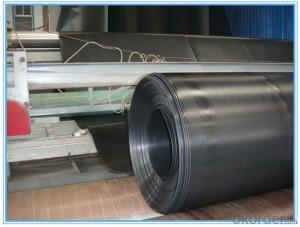

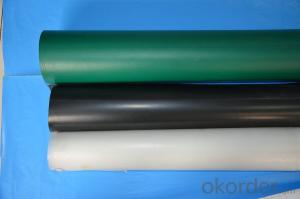

- Geomembrane is a kind of waterproof barrier material taking high-molecular polymer as the basic raw material of the, mainly divided into: low density polyethylene (LDPE) geomembrane, high density polyethylene (HDPE) geomembrane and EVA geomembrane, which have good errosion resistance to bacteria and chemistry, not afraid the erosion of acid, alkali and salt, testing their resistance to errosion during test.

- Yes, geomembranes can be used in floating covers for liquid storage tanks. Geomembranes are impermeable liners that are commonly used to contain liquids and prevent leakage. In the context of floating covers for liquid storage tanks, geomembranes can provide an additional barrier to prevent liquid from escaping and protect the stored contents from external factors such as evaporation, contamination, or adverse weather conditions.

- Geomembranes contribute to groundwater protection by acting as a barrier between contaminants and the underlying groundwater. These impermeable liners prevent the leaching of pollutants, such as hazardous chemicals or waste materials, into the surrounding soil and groundwater. By effectively containing these substances, geomembranes help to preserve the quality and purity of groundwater, ensuring its availability for drinking water, agriculture, and other essential purposes.

- Yes, geomembranes can be used in irrigation canal linings. They are commonly used as liners for canals to prevent seepage and leakage of water, ensuring efficient water distribution in irrigation systems. Geomembranes, typically made of synthetic materials like HDPE or LDPE, provide a impermeable barrier that helps to conserve water and prevent contamination of soil and groundwater.

- Yes, geomembranes are generally designed and engineered to be resistant to punctures. They are typically made from durable materials such as high-density polyethylene (HDPE), which provide strong puncture resistance. However, the specific puncture resistance of a geomembrane can vary depending on its thickness, quality, and application.

- When installing geomembranes in areas with high seismic activity, several considerations need to be taken into account. Firstly, the geomembrane material should be selected based on its ability to withstand seismic forces and potential ground movements. High-quality, flexible geomembranes that can accommodate ground deformations are typically recommended. Secondly, the design and installation of the geomembrane system should include appropriate anchoring and attachment methods to ensure that the geomembrane remains in place during seismic events. This may involve using additional fastening techniques such as anchor trenches, concrete collars, or ballasting to secure the geomembrane. Thirdly, the subgrade preparation and compaction should be done meticulously to provide a stable base for the geomembrane. Proper compaction techniques and reinforcement measures, such as geotextiles or geogrids, can enhance the stability of the subgrade and reduce the potential for differential settlement or slope failure during seismic activity. Lastly, regular inspections and monitoring of the geomembrane system should be conducted to identify any signs of damage or displacement that could compromise its integrity. This can help ensure timely repairs or reinforcement to maintain the effectiveness of the geomembrane in high seismic areas. Overall, the considerations for geomembrane installations in areas with high seismic activity revolve around material selection, anchoring methods, subgrade preparation, and ongoing monitoring to ensure the long-term performance and stability of the geomembrane system.