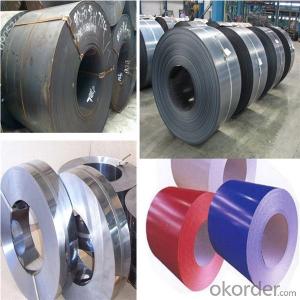

304 Or 316 Stainless Steel

304 Or 316 Stainless Steel Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For Sale304 Or 316 Stainless Steel Supplier & Manufacturer from China

Okorder.com is a professional 304 Or 316 Stainless Steel supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 304 Or 316 Stainless Steel firm in China.Hot Products

FAQ

- Type 409 and Type 410 stainless steel pipes exhibit distinct characteristics and are used for different purposes. Type 409 stainless steel is a ferritic variant containing less chromium than Type 410. It is mainly composed of iron, carbon, and up to 11% chromium. This composition grants Type 409 stainless steel adequate resistance to corrosion in low-oxygen environments and moderate resistance to pitting and crevice corrosion. It finds common usage in applications where high-temperature oxidation resistance is unnecessary, such as automotive exhaust systems, catalytic converter shells, and heat exchangers. On the contrary, Type 410 stainless steel is a martensitic variant with a higher chromium content (around 11-13%) and a small amount of nickel. This composition endows Type 410 stainless steel with exceptional corrosion resistance and favorable mechanical properties. It is a versatile stainless steel that can be subjected to heat treatment to achieve elevated strength and hardness. Type 410 stainless steel is frequently employed in applications requiring corrosion resistance and/or wear resistance, including cutlery, surgical instruments, valves, and pump parts. To summarize, the primary distinction between Type 409 and Type 410 stainless steel pipes lies in their composition and resulting properties. Type 409 stainless steel is a ferritic variant with good corrosion resistance in low-oxygen environments, whereas Type 410 stainless steel is a martensitic variant with excellent corrosion resistance, heightened strength, and hardness. The choice between these two types of stainless steel pipes depends on the specific requirements of the application and the desired properties necessary for its success.

- The maximum operating temperature for stainless steel pipes can vary depending on the grade of stainless steel used. However, in general, stainless steel pipes can typically withstand temperatures up to 1200 degrees Fahrenheit (650 degrees Celsius).

- Depending on the application and specific requirements, the wall thickness of stainless steel pipes can vary. Generally, there is a wide range of wall thickness options available for stainless steel pipes. For typical applications like plumbing or industrial use, the wall thickness can range from Schedule 5S (0.049 inches or 1.24 mm) to Schedule 80S (0.218 inches or 5.54 mm). It's worth mentioning that for specialized applications or projects with specific requirements, the wall thickness can be customized accordingly. In summary, factors such as the intended use, pressure requirements, and structural considerations should be taken into account when selecting the appropriate wall thickness for stainless steel pipes.

- Yes, stainless steel pipes are suitable for vacuum systems. Stainless steel is known for its high strength, durability, and resistance to corrosion, making it an excellent choice for vacuum applications. It offers a high level of leak-tightness, ensuring that the vacuum system can maintain the desired level of vacuum without any loss. Stainless steel pipes also have low outgassing rates, which is crucial in maintaining a clean and contaminant-free vacuum environment. Additionally, stainless steel is compatible with a wide range of gases and fluids commonly used in vacuum systems, making it a versatile material for various applications. Overall, stainless steel pipes are a reliable and effective option for vacuum systems due to their excellent mechanical properties and resistance to both internal and external factors that can affect the performance of the vacuum.

- Yes, stainless steel pipes can be bent or curved. Stainless steel is a versatile material that can be easily formed into various shapes, including bends and curves. This flexibility is due to its excellent ductility and high tensile strength. Stainless steel pipes are commonly bent or curved to fit specific design requirements in industries such as construction, automotive, and manufacturing. The bending process can be achieved through various methods, including hot bending, cold bending, and mandrel bending, depending on the desired shape and specifications. It is important to note that the bending or curving of stainless steel pipes should be done with proper equipment and expertise to ensure the integrity and quality of the pipe.

- The maximum diameter of stainless steel pipes available can vary depending on the manufacturer and supplier. However, stainless steel pipes typically range from smaller diameters, such as ½ inch or 1 inch, to larger diameters, such as 36 inches or even more. It is important to note that the availability of larger diameters may be limited and may require special ordering or customization. Therefore, it is advisable to consult with specific manufacturers or suppliers to determine the maximum diameter of stainless steel pipes they offer.

- Yes, stainless steel pipes are suitable for air conditioning systems. They offer excellent corrosion resistance, durability, and can withstand high temperatures and pressure levels commonly found in air conditioning systems. Stainless steel pipes also ensure clean air quality and are easy to maintain, making them a reliable choice for air conditioning installations.