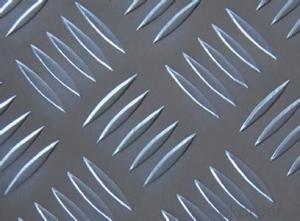

1/4 Checkered Plate Weight

1/4 Checkered Plate Weight Related Searches

Led Light Bulbs For Ceiling Fixtures Decorative Ceiling Plate For Light Fixture Ceiling Plate For Hanging Light Parts For Light Fixtures Light Projector For Christmas Grill With Led Light Bar Lights For Kitchen Ceiling Lights For Fall Ceiling Hanging Ceiling Chairs For Bedrooms 42 White Ceiling Fan With LightHot Searches

Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Price Of Shipping Containers For Sale Stock Price For Aluminum Air Pump For Aquarium Price Used Foam Board Insulation For Sale Bags Of Cement For Sale Types Of Temporary Side Panels For Cement Deck Magnesium Oxide Board For Sale Hdf Board For Sale sintra board for sale Solar With Inverter Price Pedestal Fan With Water Spray Price Price Of Scrap Stainless Steel Price Of Stainless Steel Scrap Price Of Stainless Steel High Mast Light Price List Solar High Mast Light Specification Inverter Size For Solar System1/4 Checkered Plate Weight Supplier & Manufacturer from China

Okorder.com is a professional 1/4 Checkered Plate Weight supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 1/4 Checkered Plate Weight firm in China.Hot Products

FAQ

- Yes, steel sheets can be used for water-resistant applications. Steel is a durable and corrosion-resistant material, making it suitable for various water-related purposes such as water tanks, roofing, and siding. Proper coatings and treatments can further enhance its water resistance capabilities.

- Yes, steel sheets are relatively easy to install due to their lightweight nature and modular design. They can be easily maneuvered and fastened into place, making the installation process efficient and straightforward.

- Steel sheets can be packaged in a variety of ways, depending on their size, shape, and intended use. Some common packaging options are: 1. Wooden crates: To ensure safe transportation, steel sheets are often packed in sturdy wooden crates. Straps or bands are used to secure the sheets inside the crate and prevent any movement. 2. Steel frames: Another option is to package steel sheets in steel frames, which provide extra protection and stability. This is especially useful for large or heavy sheets, as the frame securely holds them in place during transit. 3. Coil packaging: When steel sheets are in coil form, they are typically wrapped in plastic or paper to protect them from moisture and dust. These wrapped coils are then placed on pallets for easy handling and transportation. 4. Bundles: Steel sheets can also be bundled together using steel straps or bands. This method is commonly used for smaller sheets or when multiple sheets need to be packaged together. Shrink wrap or plastic covers can be added to further secure the bundles during shipping. 5. Custom packaging: Depending on specific requirements or customer preferences, steel sheets can be packaged in custom-designed packaging. This may involve using foam padding or inserts to protect delicate surfaces, or specialized containers for specific applications like food-grade steel sheets. In conclusion, the packaging options for steel sheets are diverse and can be customized to suit different industries and customers. The choice of packaging depends on factors such as sheet size, weight, required protection level, and transportation method.

- No, steel sheets cannot be used for automotive fuel tanks as steel is prone to corrosion and can contaminate the fuel. Automotive fuel tanks are typically made of materials such as high-density polyethylene (HDPE) or aluminum, which are resistant to corrosion and provide better fuel compatibility.

- The specifications for steel sheets used in construction can vary depending on the specific project requirements. However, common specifications generally include the steel grade (such as ASTM A36 or ASTM A572), the thickness (measured in gauge or millimeters), the width and length dimensions, the surface finish (such as hot rolled or cold rolled), and any additional properties like corrosion resistance or fire resistance. These specifications ensure that the steel sheets meet the necessary strength, durability, and safety standards for their intended use in construction applications.

- Yes, steel sheets are suitable for interior wall cladding. They offer durability, strength, and a modern aesthetic, making them a popular choice for commercial and residential interiors.

- Automotive manufacturing can benefit from the utilization of steel sheets for several reasons. Firstly, the high strength and durability of steel sheets make them well-suited for enduring the demanding conditions and stresses encountered by vehicles on the road. This remarkable strength ensures the production of safer and more dependable vehicles, as steel sheets provide a robust protective structure capable of absorbing impact energy in the event of a collision. Secondly, steel sheets possess exceptional formability, allowing them to be easily shaped and molded into various intricate designs required for automotive components. This adaptability permits the creation of precise and elaborate parts, guaranteeing a flawless fit and optimal performance. Moreover, steel sheets exhibit commendable resistance to corrosion, a crucial characteristic for automotive applications. Vehicles encounter a variety of environmental factors such as moisture, salt, and chemicals, which can lead to rust and corrosion. However, by utilizing steel sheets with protective coatings, manufacturers can ensure that their vehicles have an extended lifespan and preserve their aesthetic appeal. Additionally, steel sheets present themselves as a readily available and cost-effective alternative to other materials used in automotive manufacturing. Steel is extensively utilized in numerous industries, which has resulted in the establishment of a well-developed supply chain for steel sheets. This accessibility not only guarantees a consistent supply for automotive manufacturers but also assists in maintaining manageable production costs. Lastly, steel sheets possess excellent thermal conductivity, which is essential for effective heat dissipation in automotive applications. Vehicles generate a substantial amount of heat, particularly in the engine and exhaust systems. Steel sheets aid in efficiently transferring and dissipating this heat, preventing overheating and ensuring optimal performance. In conclusion, the advantages of utilizing steel sheets in automotive manufacturing encompass high strength and durability, exceptional formability, commendable resistance to corrosion, cost-effectiveness, and efficient heat dissipation. These factors make steel sheets the preferred choice for the production of safe, reliable, and long-lasting vehicles.