Tower Crane CMAX TC6014 Construction Machiney

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

Tower Crane is a machinery used for vertical lifting and horizontal delivering of building materials and any other heavy items during construction process. It can lift and lay down, horizontally shift, and rotate, so the working range is very large. The whole body can be fixed or movable.

Features:

1. It has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed.

2. The range-change structure drives the dolly to change range on the horizontal arm, with good positioning performance. Planet gear decelerator is applied in the circumgyrating structure, together with moment-limiting hydraulic coupler, which can relize high load capacity, steady starting and reliable operation.

3. The crane has complete set of safety devices, which can guarantee the safe and high efficienct operation of the equipment. The machine is equipped with lifting height limiter, dolly range-change limiter, moment limiter, weight limiter, circumgyrating limiter, etc.

4. The operator's room is set independently on one side, with good vision field. It creates a good working environment for the operator.

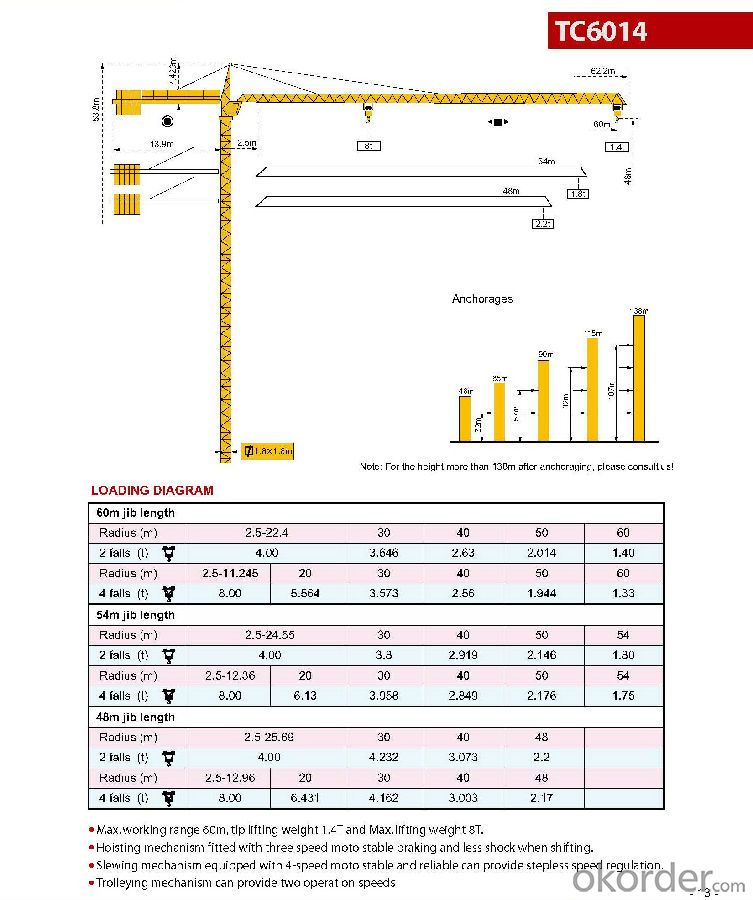

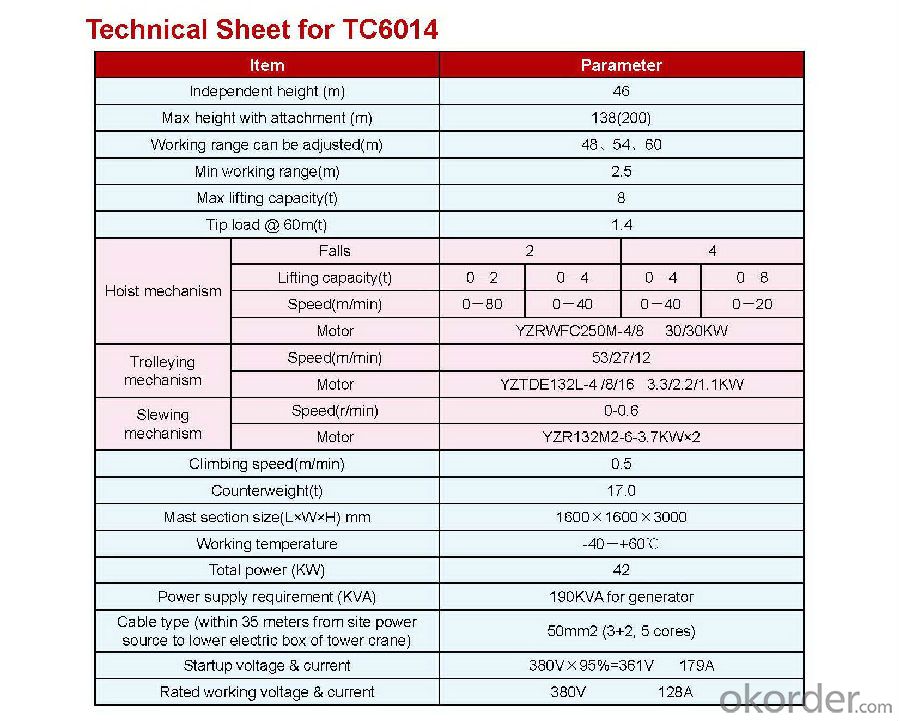

Specifications:

- Q:Where are gears used on a crane?

- It's more a matter of where gears MIGHT be used. 1. Gear reduction to lifting cable drum. 2. Gears to rotate the crane, or driving cable drum to extend jib. 3. If a mobile crane, gears to transmit drive to wheels/ tracks etc.

- Q:total motor kw-100kw,crane class-m6,the crane should be operated on ups as the conventional electric supply is off , back up time require-30 min.

- To account for the inefficiencies, and startup currents, you should have a 200 kW (200 kVA) inverter with peak power of 800 kW. The batteries would have to store and deliver about 150 kW. But lead acid batteries would need to be of a higher capacity to guarantee that power level for 1/2 hour, which calculates to 75 kW-hour. I'd say 100 kW-hour capacity. A large 12 volt battery can store about 100 amp-hours which translates to 1 kW-hour, so you would need 100 of this size batteries connected in series/parallel. I made a lot of guesses, you should get better numbers for the motors, the inverters and batteries for a more accurate calculation. An inverter of the size needed will not be a 12 volt unit, but probably 48 or 96 volts DC. so you need to configure your batteries in series parallel to get that voltage. Altogether, the 100 large batteries make this not a practical solution. There are lots of large cranes in the world, what do they use for backup? And why do you need backup. With no power, the clutches would keep the crane and loads fixed in position, my guess.

- Q:What are the conditions of tower cranes, strictly prohibited?

- Tower cranes are prohibited under any of the following circumstances:1, the state explicitly eliminated products;2, more than the required service life, failed to assess the quality of products;3, products that do not meet the current relevant standards of the state;4, there is no complete security technical records of the product.Tower crane (tower crane) is called tower crane, also known as tower crane, originated in Western europe. A revolving crane mounted on top of a tall tower. The working space is large, mainly used for the vertical and horizontal transportation of materials and the installation of building components during the building construction. It consists of three parts: metal structure, working mechanism and electrical system.

- Q:like a really really clear set of instructions. or a video. but evrything i have tried confused me.

- This okorder

- Q:What should I do with them? who would accept them if I donated them?

- Maybe go to a children's hospital and see if they will accept it. If they won't maybe they will know of an organization that will.

- Q:The really really tall ones you see next to skyscrapers. How do they assemble them? I thought that maybe they use another crane, but then how did they assemble that crane? Some of them are really, really tall. Try to remember what one looks like. They have long hollow necks with a top section where the driver sits that stretches long horizontally.

- You okorder /

- Q:How much do you know about construction cranes??

- that depends, what do u need to know

- Q:Operation points of tower crane (tower crane)?

- Slewing bearing: tower crane is one of the most critical components, mainly to bear overturning moment and vertical load. After the failure, the demolition and replacement is extremely difficult, loss of large, so you have to check carefully to do maintenance, each 200H must be a senior grease lubrication from the rotary bearing surface, until now exudation. Slewing bearing adopts high strength bolt connection, if the pretension is not enough, or long-term operation, do not check, not fastening, will cause loose. If the individual bolts loose, will cause the remaining bolts overload, the consequences will be disastrous. The luffing mechanism only moves horizontally, the load is light and the line speed is not high, so it should be easy to master and operate. However, the amplitude involves the change of the lifting torque, and if there is no stopping in time, there will be the possibility of over torque. Therefore, the main requirement of variable amplitude operation is stationary parking and accurate positioning. The tower crane is of great height and the hanger is hung longer, so it is easy to swing the hanger when it is running. This is an objective phenomenon. What is called stabilization hook operation is how to make the swinging hook stop quickly, or how to make the hook move with the movement of the crane as soon as possible, and minimize the operation of the swing. The operation of stabilization hook is the skill that the driver should master.

- Q:I only wish to know about Tower Cranes, not any other type of crane. Also only wish to know about cranes on the job, not sitting in a crane yard. I am an operator and looking to move and want to know where the work is best so a list of top five would be terrific. Thanks.

- We have been told that our state bird was a crane. That's because there are so many of them here all the time. Construction is booming in Oklahoma. I think most of them are coming from the east and west coasts. They can get a much larger house here for a whole lot less. They are sold when they are being built.

- Q:Trying to find an estimated weight for a mobiles crane with a 5 tonne capacity ?

- If the crane HAS a 5-ton capacity, then to be able to estimate the weight you would need to know the length of its lifting arm at maximum extension w.r.t the C.G. of the body of the crane. So suppose we have an arm length of (say) 6 mtrs, then the max turning moment at the fulcrum (from front wheels of crane ? ) due to the Load alone = 5 x 6 = 30 You need to add the moment for the arm itself. Lets say the arm is around 1/2 ton. And its c.g. is approx 1/3 the distance from the fulcrum. Then this adds another = 1/2 * 1/3 *6 = 1 So total moment is 30 + 1 = 31 The body of the crane must be MORE than this. Suppose the C.G. of the crane is 2 meters behind the same fulcrum. Then weight of the body must be 31/ 2 = 15.5 tons. Lets say the weight is 16 tons. Then the TOTAL mobile cranes weight would be 16 (body) + 1/2 (arm) ~ 16.5 tons It all depends on the dimensions of the crane, and where the c.g. is located. If the crane has ballast added right at the back, then it's overall weight can be made less since it's c.g. would get shifted further away from the fulcrum

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tower Crane CMAX TC6014 Construction Machiney

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords