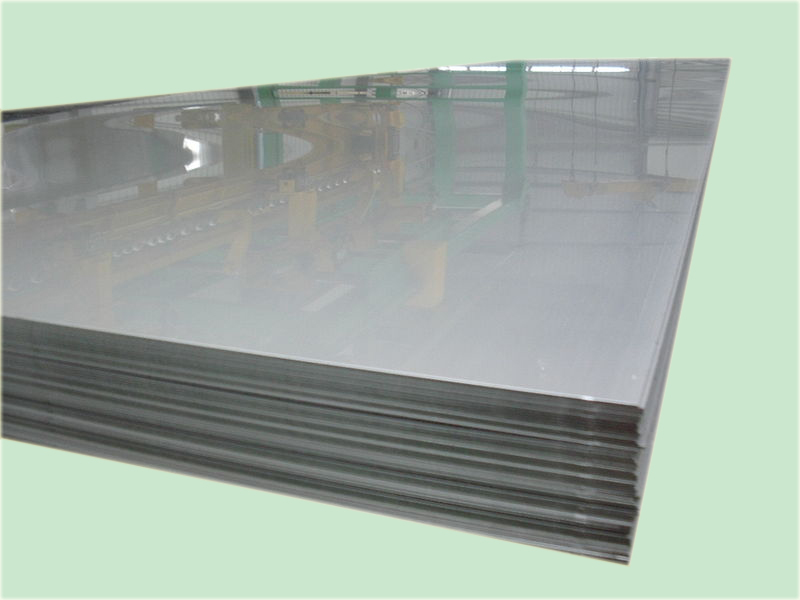

SUS304L stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

304L stainless Steel Sheet

1. Chemical composition

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

|

Max0.03 |

Max1.00 |

Max2.00 |

Max0.045 |

Max0.03 |

9.0-13.0 |

18.0-20.0 |

2. Mechanical properties

|

Yield Strength |

Tensile |

Elongation |

Hardness (HV) |

Hardness (HRB) |

|

≥175 |

≥480 |

≥40 |

≤200 |

≤90 |

3. Standard: AISI, ASTM, GB, EN, DIN, JIS

4. Surface: 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size: Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms: T/T or L/C

8. Packing: Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time: Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q:Are stainless steel strips resistant to intergranular corrosion?

- Yes, stainless steel strips are generally resistant to intergranular corrosion. This is because stainless steel contains a minimum of 10.5% chromium, which forms a protective oxide layer on the surface of the steel. This oxide layer acts as a barrier, preventing oxygen and moisture from reaching the underlying metal and causing corrosion. Additionally, stainless steel strips often contain other alloying elements such as nickel, molybdenum, or titanium, which further enhance their resistance to corrosion. However, it is important to note that the resistance to intergranular corrosion can vary depending on the specific grade of stainless steel being used and the conditions it is exposed to. Some grades of stainless steel may be susceptible to intergranular corrosion under certain circumstances, such as exposure to high temperatures or certain chemical environments. Therefore, it is essential to choose the appropriate grade of stainless steel based on the specific application and environmental conditions to ensure optimal corrosion resistance.

- Q:Can stainless steel strips be used in the petrochemical industry?

- Yes, stainless steel strips can be used in the petrochemical industry. Stainless steel is known for its excellent corrosion resistance, making it suitable for various applications in this industry. Petrochemical processes involve the handling of various chemicals, gases, and liquids, many of which can be corrosive. Stainless steel strips are often used in the construction of storage tanks, pipelines, heat exchangers, and other equipment where corrosion resistance is essential. Additionally, stainless steel's high strength and durability make it a reliable choice for petrochemical applications, as it can withstand high temperatures and pressures. Overall, stainless steel strips are a preferred material in the petrochemical industry due to their corrosion resistance, strength, and longevity.

- Q:What are the factors that affect the corrosion resistance of stainless steel strips?

- The corrosion resistance of stainless steel strips can be affected by several factors. These factors include the composition of the alloy, the formation of a passive film, the surface finish, environmental conditions, stress corrosion cracking, and the manufacturing processes. 1. The corrosion resistance of stainless steel depends on its alloy composition. Stainless steel is typically made up of iron, chromium, and other elements like nickel, molybdenum, and nitrogen. The higher the chromium content, the better the corrosion resistance. Other alloying elements also contribute to the overall corrosion resistance. 2. When stainless steel is exposed to oxygen, it forms a protective film on its surface. The stability and thickness of this film depend on factors like alloy composition, surface condition, and environmental conditions. Any damage to the film can compromise the corrosion resistance. 3. The surface finish of stainless steel strips can greatly impact their corrosion resistance. Smooth and polished surfaces are less susceptible to corrosion compared to rough surfaces, as they provide fewer areas for corrosive agents to attack. 4. The environment in which stainless steel strips are used can significantly affect their corrosion resistance. Factors like temperature, humidity, pH level, and the presence of corrosive agents like chloride ions or sulfur compounds can accelerate corrosion. Stainless steel strips used in marine, industrial, or highly corrosive environments may require higher corrosion resistance. 5. Stress corrosion cracking is a type of corrosion that stainless steel can be susceptible to, especially in environments containing chlorides or sulfides. This type of corrosion occurs due to the combined effects of tensile stress and corrosive agents, leading to the formation of cracks. The susceptibility to stress corrosion cracking can vary depending on the alloy composition and environmental conditions. 6. The manufacturing processes and heat treatment involved in producing stainless steel strips can also affect their corrosion resistance. Improper heat treatment or inadequate manufacturing processes can result in a decrease in corrosion resistance. In conclusion, the corrosion resistance of stainless steel strips is influenced by various factors, including alloy composition, passive film formation, surface finish, environmental conditions, stress corrosion cracking susceptibility, and manufacturing processes. It is important to consider these factors when choosing the appropriate grade of stainless steel for specific applications to ensure optimal corrosion resistance.

- Q:Can stainless steel strips be used in food processing applications?

- Yes, stainless steel strips can be used in food processing applications. Stainless steel is an ideal material for the food industry due to its superior corrosion resistance, durability, and hygiene properties. It is resistant to rust, staining, and chemical reactions, making it suitable for contact with various food products. Stainless steel strips are commonly used in food processing equipment such as conveyors, mixers, tanks, and cutting tools. Additionally, stainless steel is easy to clean and maintain, ensuring the highest standards of food safety and preventing contamination.

- Q:Can 111 stainless steel strips be coated with anti-fouling coatings?

- Indeed, it is possible to coat 111 stainless steel strips with anti-fouling coatings. These specialized coatings are explicitly formulated to hinder the buildup of aquatic organisms, including algae and barnacles, on surfaces that come into contact with water. Stainless steel, renowned for its resistance to corrosion and its robustness, is frequently employed in marine settings. Through the application of anti-fouling coatings, the strips can be shielded against fouling, thereby guaranteeing their endurance and efficacy within marine surroundings.

- Q:How do you prevent galling of stainless steel strips?

- One effective way to prevent galling of stainless steel strips is by applying a lubricant or anti-seize compound to the surface. This helps reduce friction and wear during sliding or rubbing contact, preventing the surfaces from seizing or sticking together. Additionally, using proper machining techniques, such as slow and steady cutting speeds, adequate cooling, and sharp cutting tools, can also minimize the risk of galling.

- Q:Can 111 stainless steel strips be used in the oil and gas industry?

- Yes, 111 stainless steel strips can be used in the oil and gas industry. 111 stainless steel is a commonly used grade of stainless steel that exhibits good corrosion resistance, high strength, and excellent formability. These properties make it suitable for various applications in the oil and gas industry, including piping, storage tanks, heat exchangers, and other equipment. Additionally, 111 stainless steel strips can withstand harsh environmental conditions, such as exposure to corrosive substances, high temperatures, and pressure, making them a reliable choice for the oil and gas industry.

- Q:What is the maximum width available for stainless steel strips?

- The maximum width of stainless steel strips can differ based on the manufacturer and supplier. Generally, these strips are typically found in widths that range from 0.5 inches to 24 inches. Moreover, certain manufacturers may provide wider strips, reaching up to 48 inches or even more, depending on their production facilities' capabilities and the specific requirements. To ascertain the precise maximum width capabilities for stainless steel strips, it is crucial to consult with individual suppliers.

- Q:Are 111 stainless steel strips suitable for chemical storage tanks?

- 111 stainless steel strips are unsuitable for chemical storage tanks. They lack the necessary corrosion resistance and durability required to withstand the aggressive chemical environments commonly encountered in storage tanks. Thus, it is crucial to utilize stainless steel grades specifically engineered for chemical storage purposes, such as 304 or 316 stainless steel. These grades exhibit superior resistance to corrosion and chemical attacks.

- Q:Are stainless steel strips easy to clean and maintain?

- Stainless steel strips are renowned for their ability to resist corrosion, stains, and rust, thus making them an ideal material for a wide range of applications. When it comes to cleaning these strips, a gentle approach is key. You can employ a mild detergent or soap in combination with warm water and a soft cloth or sponge. It's important to scrub the surface in the direction of the grain to prevent any potential scratching. Once cleaned, thoroughly rinse the strips and ensure they are completely dry to avoid water spots. In terms of upkeep, maintaining stainless steel strips requires minimal effort. Regular cleaning usually suffices to keep them in pristine condition. However, should you come across stubborn stains or marks, there are stainless steel cleaners and polishes specially formulated for this purpose. These products aid in restoring the strips' luster and eliminating any residue or imperfections. Moreover, stainless steel boasts remarkable durability, eliminating the need for special treatments or coatings to preserve its quality. It is also resistant to heat, making it a suitable choice for a variety of environments, including kitchens and manufacturing facilities. All in all, thanks to their inherent qualities, stainless steel strips are relatively simple to clean and maintain. By adhering to proper cleaning techniques and utilizing appropriate products, you can ensure that your stainless steel strips remain in exceptional condition for an extended period.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong,China |

| Year Established | 2005 |

| Annual Output Value | Above US$5.3 Million |

| Main Markets | Europe, China |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tian Jin |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 40 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

SUS304L stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords