Steel Frame Formwork for Light Duty Frame Formwork

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Frame Formwork-Light duty frame formwork

Light duty steel frame of this kind is weighing lightly while bearing high capacity and in some sense it will reduce human cost for customers.

2. Main Features of light duty steel frame formwork

-Simply assemble and disassemble.

-Film faced plywood used to repeat its use with almost 40 times

-Smooth concrete surface to reduce post processing fees.

-Accessories used effectively(such as nail, steel wire, tie rod..).

-Adjustable sizes (1200 steel frame formwork can be adjusted from minimum300mm to maximum 1050mm)

-Easy to move and remove

-Parts used in column steel frame formwork can be used in wall steel frame formwork

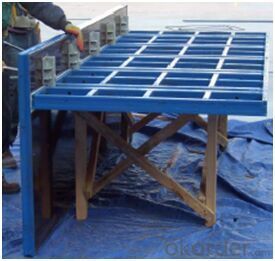

3. Light Duty Steel Frame Formwork Images

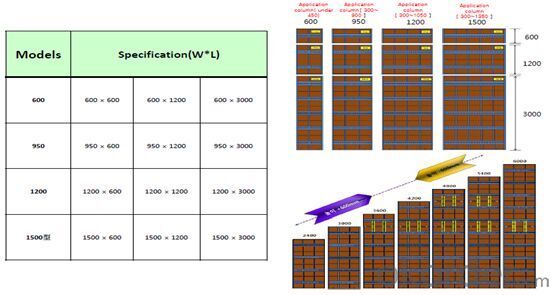

4. Light Duty Steel Frame Formwork Specifications

Column steel frame formwork sizes

5. FAQ of Light Duty Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the Light Duty Steel Frame Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q:What are the environmental impacts of using steel frame formwork?

- The environmental impacts of using steel frame formwork are relatively low compared to other construction materials. Steel is a highly durable and recyclable material, which means it has a longer lifespan and can be reused or repurposed. This reduces the need for raw material extraction and minimizes waste. However, the production of steel does require a significant amount of energy, which contributes to greenhouse gas emissions. Additionally, if not properly managed, the disposal of steel formwork can have negative environmental impacts. Nonetheless, overall, steel frame formwork is considered a more sustainable option in construction due to its durability and potential for reuse.

- Q:Can steel frame formwork be used in areas with limited access?

- Yes, steel frame formwork can be used in areas with limited access. Steel frame formwork is known for its versatility and adaptability, making it suitable for various construction projects, regardless of the accessibility of the area. Its modular design allows for easy transportation and assembly, enabling it to be used in tight spaces or areas with limited entry points. Additionally, steel frame formwork can be dismantled and reassembled quickly, making it ideal for projects in areas where access is restricted or challenging.

- Q:What types of construction projects are steel frame formwork commonly used for?

- Steel frame formwork is commonly used for various types of construction projects, including high-rise buildings, bridges, dams, tunnels, and other large-scale concrete structures.

- Q:What are the different types of safety features incorporated in steel frame formwork systems?

- There are several different types of safety features that are commonly incorporated in steel frame formwork systems. These safety features are designed to ensure the protection and well-being of workers and to prevent accidents and injuries on construction sites. Some of the most common safety features include: 1. Guardrails: Steel frame formwork systems often come equipped with guardrails, which are installed along the edges of the formwork to provide a physical barrier and prevent workers from falling. 2. Toe boards: Toe boards are another common safety feature in steel frame formwork systems. These boards are installed at the bottom of the formwork to prevent tools, materials, or debris from falling and potentially causing injury to workers below. 3. Safety nets: Safety nets are often used in conjunction with steel frame formwork systems to provide an additional layer of protection against falls. These nets are typically installed below the formwork and can catch workers or objects in case of a fall. 4. Access platforms and ladders: Steel frame formwork systems often include access platforms and ladders to ensure safe and easy access to the formwork. These platforms and ladders are designed to be sturdy and secure, allowing workers to move up and down the formwork safely. 5. Fall arrest systems: Fall arrest systems, such as harnesses and safety lines, are commonly used in conjunction with steel frame formwork systems to provide individual protection against falls. These systems are designed to arrest a fall and prevent a worker from hitting the ground. 6. Warning signs and labels: Safety is enhanced by the incorporation of warning signs and labels on steel frame formwork systems. These signs and labels provide important information about potential hazards, safety precautions, and instructions for proper use. Overall, the incorporation of these safety features in steel frame formwork systems helps to create a safe working environment, minimize the risk of accidents, and protect the well-being of workers on construction sites.

- Q:How does steel frame formwork prevent the formation of air voids or honeycombs in the concrete?

- Steel frame formwork prevents the formation of air voids or honeycombs in concrete by providing a rigid and tightly enclosed structure that holds the concrete in place during pouring and curing. This prevents the concrete from seeping or leaking out, ensuring a consistent and compacted mixture that minimizes the likelihood of air pockets or voids forming.

- Q:Can steel frame formwork be used for both indoor and outdoor construction projects?

- Yes, steel frame formwork can be used for both indoor and outdoor construction projects. Steel frame formwork is known for its durability, strength, and versatility, making it suitable for various construction applications, regardless of the project's location. Whether it is used for constructing building foundations, walls, columns, or slabs, steel frame formwork can withstand the elements and provide reliable support and stability. Additionally, steel frame formwork is highly adaptable and can be easily adjusted to accommodate different shapes and sizes, making it an ideal choice for both indoor and outdoor construction projects.

- Q:Can steel frame formwork be used for curved or irregular shaped structures?

- Yes, steel frame formwork can be used for curved or irregular shaped structures. Steel formwork is highly versatile and can be easily adjusted and modified to accommodate different shapes and sizes. It offers great flexibility and can be curved or bent to fit the desired shape of the structure. Additionally, steel formwork is known for its strength and durability, making it suitable for complex and irregular structures. The steel frame can be customized and fabricated to match the specific requirements of the project, allowing for efficient and accurate construction of curved or irregular shaped structures.

- Q:Stone curtain wall steel frame in the 90 degree angle of the horizontal frame connection

- According to the intersection of two face stone curtain wall

- Q:How does steel frame formwork handle the placement of MEP (mechanical, electrical, plumbing) systems within the concrete structure?

- Steel frame formwork is a versatile and efficient system that can easily handle the placement of MEP systems within a concrete structure. The steel frames provide a sturdy and reliable support structure that allows for the seamless integration of MEP components. One of the key advantages of steel frame formwork is its adaptability. The frames can be easily modified and customized to accommodate the specific requirements of MEP systems. This includes creating openings and penetrations for pipes, conduits, ducts, and other essential components. The flexibility of steel frame formwork ensures that MEP systems can be efficiently incorporated into the concrete structure without compromising its integrity. Additionally, steel frame formwork offers excellent load-bearing capabilities. This is crucial when considering the weight and potential vibrations associated with MEP systems. The strong and durable nature of the steel frames ensures that they can withstand the weight and movement of MEP components, providing a stable and secure platform for their installation. Furthermore, steel frame formwork allows for precise and accurate placement of MEP systems. The frames can be easily aligned and leveled, ensuring that the MEP components are installed with precision. This is particularly important in complex MEP installations, where accuracy is crucial to avoid clashes or conflicts between different systems. Moreover, steel frame formwork simplifies the installation and maintenance of MEP systems. The frames provide easy access to the MEP components, allowing for convenient installation, inspection, and maintenance. This accessibility ensures that any repairs or modifications can be carried out efficiently, reducing downtime and minimizing disruptions to the concrete structure. In summary, steel frame formwork is a highly efficient and effective system for handling the placement of MEP systems within a concrete structure. Its adaptability, load-bearing capabilities, precision, and accessibility make it an ideal choice for integrating MEP components seamlessly into the construction process.

- Q:How does steel frame formwork prevent the formation of surface defects in the concrete?

- To ensure the smooth and accurate placement of concrete during construction, steel frame formwork plays a vital role in preventing surface defects. Firstly, it offers a stable and rigid structure that prevents any movement or shifting during pouring and curing. This stability allows the concrete to settle evenly, reducing the risk of cracks or unevenness. Secondly, the durability and resistance to deformation of steel frame formwork ensure it can withstand the pressure exerted by the concrete without bending or warping. This prevents any distortions that could lead to imperfections in the concrete. Additionally, the smooth and seamless design of steel frame formwork minimizes the chances of concrete leakage or seepage, which can cause honeycombing or voids. By containing the concrete effectively, it ensures a consistent and defect-free surface finish. Furthermore, steel frame formwork allows for precise control over the pouring process, easily adjusted and leveled for accurate placement and uniform thickness. This precision prevents unevenness or irregularities, resulting in a smoother and more aesthetically pleasing end product. In conclusion, steel frame formwork maintains stability, durability, smoothness, and precision to prevent surface defects in concrete, resulting in a high-quality finish without imperfections.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Frame Formwork for Light Duty Frame Formwork

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords