Stainless Steel Coil Cold Rolled 304 With High Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Coil Cold Rolled 304 With Good Quality

1.Structure of Stainless Steel Coil Cold Rolled 304 With Good Quality

Cold Rolled stainless steel Coil with good quality is one of the raw material of the cold rolled stainless steel Coil, which can be used

directly in many places. Stainless Steel (Stainless Steel) is short for acidproof Stainless Steel, resistant to weak corrosive medium

such as air, steam, water, or with a Stainless Steel grade.

2.Main Features of Prefabricated Steel Structure High Building Project

The purpose of the different requirement for welding performance are different.1 Kind of tableware generally do not require the performance

of welding, even including some pot class enterprise. But the vast majority of products all need raw materials welding performance is good,

like the 2 kinds of tableware, thermos flask, steel pipes, water heaters, water dispensers, etc.

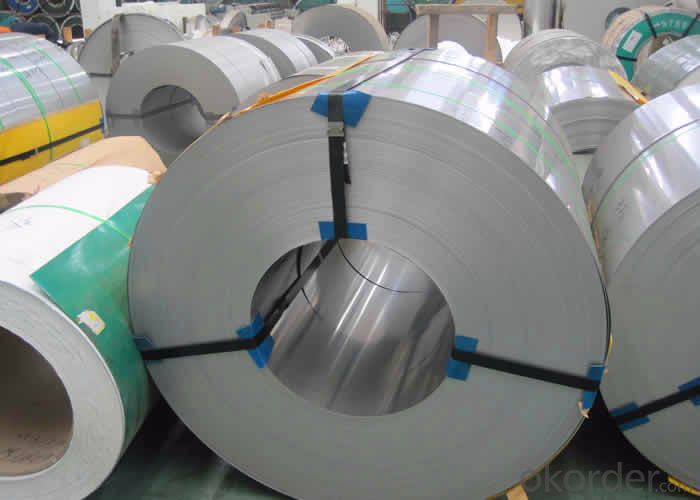

3. Stainless Steel Coil Cold Rolled 304 With Good Quality Images

4. Stainless Steel Coil Cold Rolled 304 With Good Quality Specification

Austenitic stainless steel The title Chromium is more than 18%, still contain about 8% of the nickel and small amounts of molybdenum,

titanium, nitrogen and other elements. Good comprehensive performance, corrosion resistant to a variety of media. Number of austenitic

stainless steel is commonly used one cr18ni9, 0 cr19ni9, etc. In the Wc < 0.08% 0 cr19ni9 steel, steel grade is marked as "0". This class

contains large amounts of Ni and Cr in steel, make steel in austenitic state at room temperature. This kind of steel has good plasticity

and toughness, weldability and corrosion resistance and nonmagnetic or weak magnetic, the corrosion resistance in oxidizing and reducing

medium are good, used to make acid equipment, such as corrosion resistant containers and equipment lining, pipelines, nitric acid

resistant equipment parts, etc., also can be used as the main body of watches and clocks jewelry stainless steel material. Austenitic

stainless steel with solid solution treatment, the steel heating to 1050 ~ 1150 ℃, then water-cooled or air-cooled, for single-

phase austenitic organization.

5. Applications of Stainless Steel Coil 304 With Good Quality

1. Kitchenware: tableware, cookware, Stoves…

2. Food packing: storage cans, food containers…

3. Construction: bridge, roofing, wall, decoration, bathroom accessories…

4. Precision instruments: electrical products, aerospace…

5. Others: automotive parts, machine building, chemical processing, farming…

6.FAQ of Stainless Steel Coil 304 With Good Quality

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory.

Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM

casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict

quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary

follow-up service assurance.

③How is the packaging and delivery?

Standard export packing (Coil: waterproof paper + protective steel ring; Circle: wooden box), or as your requirement and the delivery term

is based on the project.

④How long can we receive the product after purchase?

In the purchase of product within 20 working days, We will arrange the factory delivery as soon as possible. The specific time of receiving

is related to the state and position of customers. Commonly 20 to 40 working days can be served.

- Q:What is the cost of stainless steel strips?

- The cost of stainless steel strips can vary depending on several factors such as the grade of stainless steel, the thickness and width of the strips, and the quantity being purchased. Additionally, market conditions and the supplier's pricing strategy can also affect the cost. Generally, stainless steel strips can range in price from a few dollars per pound to several hundred dollars per pound. It is recommended to contact various suppliers and provide them with the specific requirements to obtain accurate pricing information.

- Q:Can stainless steel strips be used in the oil and gas industry?

- Yes, stainless steel strips can be used in the oil and gas industry. Stainless steel is known for its corrosion resistance, high strength, and durability, making it ideal for various applications in this industry, including pipelines, storage tanks, and offshore structures. It is capable of withstanding harsh environments and is resistant to corrosion caused by exposure to oil, gas, and other chemicals, making it a reliable material choice in the oil and gas sector.

- Q:Can stainless steel strips be used in electrical enclosures?

- Indeed, electrical enclosures can incorporate stainless steel strips. The preference for stainless steel in electrical enclosures stems from its resilience against corrosion, commendable durability, and capacity to endure challenging surroundings. Stainless steel strips can serve as reinforcements for the enclosure's structure or contribute to grounding. Moreover, stainless steel boasts commendable electrical conductivity, rendering it suitable for electrical applications. Accordingly, it is crucial to select the precise grade of stainless steel that aligns with the enclosure's distinct requirements, guaranteeing peak performance and longevity.

- Q:Can stainless steel strips be used in the mining industry?

- Yes, stainless steel strips can be used in the mining industry. Stainless steel is a versatile and durable material that offers excellent resistance to corrosion, high temperatures, and mechanical stress. These properties make it suitable for various applications in the mining industry. Stainless steel strips can be used in mining equipment and machinery, such as conveyors, crushers, screens, and tanks. They are commonly used for lining chutes and hoppers, as well as for fabricating wear-resistant parts and components. Stainless steel strips can also be used in the construction of mining infrastructure, such as pipelines, storage tanks, and processing plants. The mining industry often operates in harsh environments, including exposure to corrosive chemicals, abrasive materials, and extreme temperatures. Stainless steel's resistance to corrosion and high-temperature performance make it an ideal choice for applications where other materials may deteriorate quickly. Furthermore, stainless steel is easy to clean and maintain, which is crucial in the mining industry where cleanliness is essential for optimizing operational efficiency, reducing downtime, and ensuring product quality. In summary, stainless steel strips can be effectively used in the mining industry due to their corrosion resistance, high-temperature performance, durability, and ease of maintenance. They provide a reliable and long-lasting solution for various applications in mining equipment, machinery, and infrastructure.

- Q:Can 111 stainless steel strips be used in the construction industry?

- Yes, 111 stainless steel strips can be used in the construction industry. Stainless steel strips are widely used in various construction applications such as roofing, cladding, structural supports, and decorative elements. The specific grade 111 may have certain properties that make it suitable for specific construction purposes, such as enhanced corrosion resistance or high strength. However, it is important to consult with an engineer or construction professional to ensure that the grade and specifications of the stainless steel strips meet the project requirements.

- Q:Can stainless steel strips be used in railway applications?

- Stainless steel strips are indeed applicable for use in railway applications. Renowned for their resistance to corrosion and exceptional durability, stainless steel proves to be a fitting material for railway components that endure harsh weather conditions and heavy loads. Various railway applications, including track fastening systems, rail joints, signaling equipment, and electrical connections, can benefit from the utilization of stainless steel strips. Incorporating stainless steel strips in railway applications significantly contributes to the longevity and dependability of the railway infrastructure.

- Q:What are the different types of finishes for stainless steel strips?

- There are several different types of finishes available for stainless steel strips, each offering a unique aesthetic and functional quality. The most common types of finishes include: 1. No. 1 Finish: Also known as hot rolled annealed and pickled (HRAP), this finish is achieved by annealing the stainless steel strip and then pickling it to remove any scale or roughness. It results in a dull, non-reflective surface with a coarse texture. 2. No. 2B Finish: This is the most widely used stainless steel finish, characterized by a smooth, reflective surface. It is achieved by cold rolling the strip and then annealing it followed by a final light cold rolling pass to obtain the desired brightness. 3. No. 2D Finish: Similar to the No. 2B finish, but with a slightly duller and less reflective surface. It is achieved by cold rolling the strip to a thinner gauge, resulting in a smoother appearance. 4. No. 3 Finish: Also known as a ground finish, this type of finish is achieved by grinding the surface of the stainless steel strip with progressively finer abrasive materials. It creates a unidirectional grain pattern that is smooth to the touch. 5. No. 4 Finish: This is a brushed or satin finish that provides a more refined appearance. It is achieved by mechanically polishing the stainless steel strip with a series of abrasive belts or brushes to create a consistent, fine-grained finish. 6. No. 5 Finish: Similar to the No. 4 finish, but with a higher level of polish. It is achieved by using finer abrasive materials and additional polishing steps to create a mirror-like, highly reflective surface. 7. BA (Bright Annealed) Finish: This is a mirror-like finish achieved by annealing the stainless steel strip in a controlled atmosphere, followed by a final cold rolling pass. It provides the highest level of reflectivity and is commonly used in decorative applications. It's important to note that these finishes can vary in appearance and quality depending on the stainless steel grade and manufacturing process. The choice of finish depends on the intended application, desired aesthetics, and functional requirements of the stainless steel strip.

- Q:What is the hardness of stainless steel band 3/4?

- 304 stainless steel is the United States materials and Testing Association (ASTM) named SUS 304 stainless steel brand abbreviation. 304 stainless steel, 1Cr18Ni9., is a widely used austenitic stainless steel.

- Q:What are the common width tolerances for stainless steel strips?

- The specific requirements and standards set by the manufacturer or industry can cause the common width tolerances for stainless steel strips to vary. Nonetheless, typically, stainless steel strips commonly have width tolerances within the range of +/- 0.005 to 0.030 inches. These tolerances guarantee that the strips are manufactured within the specified width range, ensuring consistent and precise dimensions. It is crucial to acknowledge that the tolerance requirements may differ depending on the application and industry. Therefore, it is recommended to consult the manufacturer or relevant standards to determine the specific tolerances required for a particular stainless steel strip.

- Q:Can stainless steel strips be used in the production of chemical tanks?

- Yes, stainless steel strips can be used in the production of chemical tanks. Stainless steel is highly resistant to corrosion and chemical reactions, making it a suitable material for storing and transporting various chemicals. The durability and strength of stainless steel strips make them ideal for constructing chemical tanks that require long-term reliability and safety.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Coil Cold Rolled 304 With High Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords