PVC Coated Polyester Geogrid Warp for Railway and Road

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Type: | Geogrids | Place of Origin: | Shandong, China (Mainland) | Brand Name: | CMAX

|

Model Number: | polyester geogrid | Material: | Polyester | note: | plastic geogrid |

tensile strength: | 15,20,25,30,40,50,60,70,80,90,100,110,120 and so on | mesh size: | 36mm*36mm | roll size: | 3.95*100m or 3.95*50m |

certificate: | CE ISO |

Packaging & Delivery

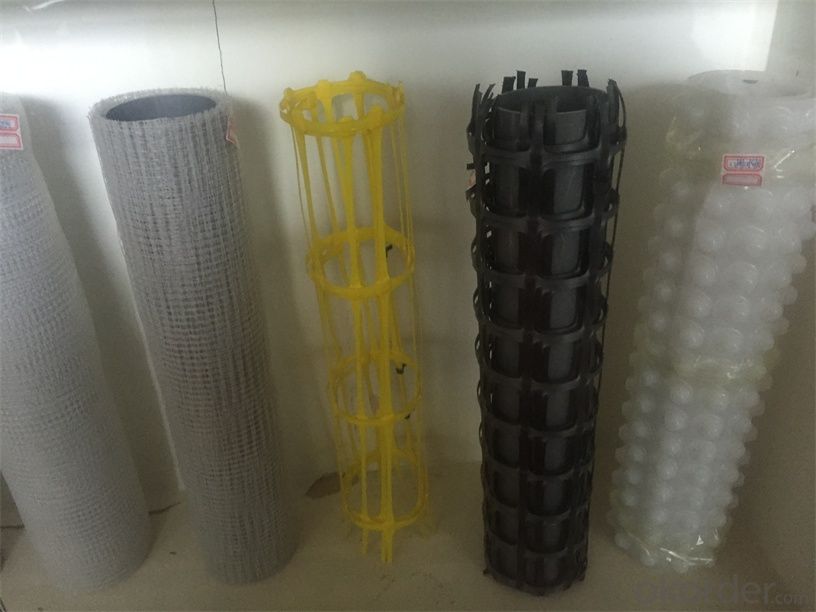

Packaging Details: | plastic geogrid packing in roll or customized |

Delivery Detail: | 5 days |

Reinforcement Polyester Geogrid :

(Warp Knitted Polyester Geogrid) :

Size | PET30/30--PET400/400; PET40/30--PET600/30 |

Price:FOB QINGDAO PORT | USD 0.3/Sq.m -- 5.0/Sq.m (LARGER QUANTITY WITH NICE PRICE) |

Packing in Roll

|

Roll width 3.95 Meter, 168 rolls in one 40HC Container.

|

Tensile strength at break | 30kn~600kn |

Stretching ratio | 13% |

Grid size | 12.7*12.7mm, 25.4*25.4mm, 50.8*50.8mm |

Mesh size | 9*9mm, 20*20mm, 35*35mm |

Roll width | 1.5m, 2m,3m,3.95m,5.8m |

Roll length | 50m, 100m |

Coating | PVC |

40HC container: | about 20000 Sq.m --50000 Sq.m |

Customize: | You can get more than what you pay for. Min 10000Sq.m |

Place of Origin | SHANDONG DAGENG, TAIAN CITY, SHANDONG, CHINA. |

Certificate | ISO ,CE |

Polyester Geogrid

Polyester Geogrid known as PET Grid is woven by high strength polymer yarns as per desired mesh sizes and strength from 20kN/m to 800kN/m(Biaxial type), 40-25kN/m to 600-400kN/m(Uniaxial type). Woven PET Grid is created through interlacing, usually at right angles, two or more yarns or filaments. Exterior of PET Grid is coated with polymer or nontoxic substance material for UV, acid and alkali resistance and prevents the bio-decomposition.

PET Grid is widely introduced to the various fields of civil engineering, transportation engineering, and environment issues. The reinforced steep slopes, reinforced retaining earth walls, reinforced embankments, reinforced abutments and piers are typical applications where geogrids are used. The resulting grid structure possesses large openings that enhance interaction with filling material.

1. Product introduction:

High strength polyester filament warp knitting geogrid select high strength synthetic fiber as raw material,adopt warp knitting oriented structure,and no curving between latitude and longitude fiber,use high strength filament on the intersection point to form firm bonding point,and fully perform the mechanical property.

2.Product features:

High strength polyester filament warp knitting geogrid possesses the characters of high intensity high module low creep deformation anti-aging anti-embrittlement high tensile strength big anti-peel strength strong binding force with soil and crushed stone and pre-design property and so on.

3. Application range:

1).Enhancement of soft roadbed of each kind of high grade road and railway,isolate different base material

2).Strengthen and stable river and slope of embankment.

3).Strengthen and stable each kind of base.

4).Strengthen the bridge and road surface.

FAQ

1. Can you send samples to us ?

Yes , free samples could be provided , but customer need pay for the freight cost .

After order placed , the freight charge could be refund .

2. What’s your Payment term ?

T/T , L/C , Western Union,Paypal ...

3. What’s your delivery method ?

By sea , By train , etc

4. What's your MOQ quantity ?

MOQ is one 20'container , the quantity could be negotiable

MOQ is one 20'container , the quantity could be negotiable

| |||||

- Q:Peel force mainly in the size of raw materials

- The tensile strength of the welded joints!

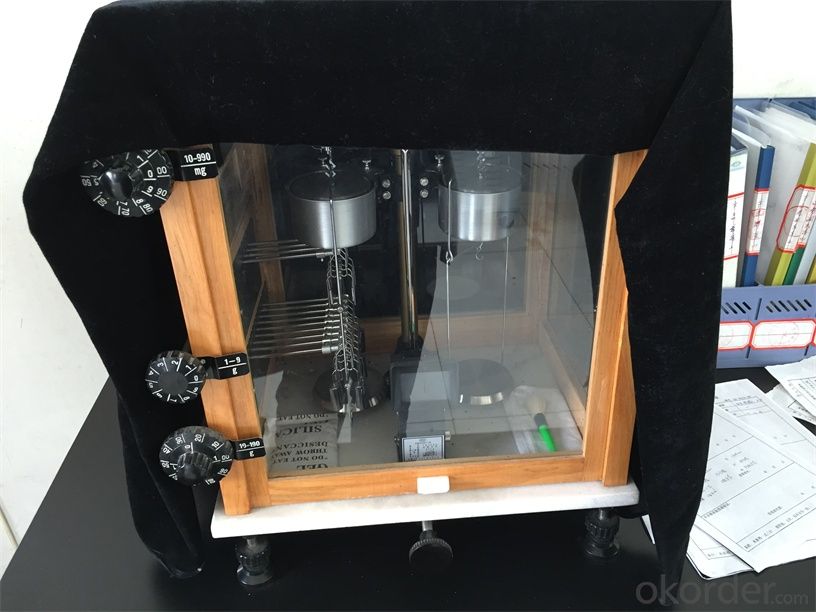

- Q:What are the standards for geogrid testing and certification?

- The standards for geogrid testing and certification typically include various parameters such as tensile strength, junction strength, aperture size, creep behavior, and durability. These tests are conducted according to industry-recognized standards such as ASTM D6637, ISO 10319, and GRI-GG2. The certification process ensures that geogrids meet the required performance criteria and can be used effectively in geotechnical applications.

- Q:Are there any limitations or drawbacks of using geogrids?

- Yes, there are limitations and drawbacks to using geogrids. Some of the limitations include the need for proper installation and compaction to achieve desired performance, as well as the requirement for an appropriate soil structure to effectively interlock with the geogrid. Additionally, geogrids may not be suitable for certain soil types, such as highly compressible or expansive soils. Other drawbacks include potential damage during installation, high cost compared to conventional soil reinforcement methods, and potential long-term degradation due to environmental factors.

- Q:How do geogrids improve the performance of mechanically stabilized slopes in high rainfall areas?

- Geogrids enhance the performance of mechanically stabilized slopes in high rainfall areas by providing additional strength and stability to the soil. They act as a reinforcement material, effectively distributing the load and reducing the potential for slope failure. Additionally, geogrids prevent soil erosion by minimizing surface runoff and facilitating water drainage, thus preserving the integrity of the slope even during heavy rainfall events.

- Q:Can geogrids be used in water drainage applications?

- Yes, geogrids can be used in water drainage applications. Geogrids are often employed to reinforce and stabilize soil, and they can help improve the effectiveness of water drainage systems by preventing soil erosion, enhancing filtration, and promoting better water flow.

- Q:What is the coefficient of friction of Nonwoven Geotextiles (polypropylene)?

- Such as artificial lakes, swimming pools, reservoirs and other projects, and geotextile is generally used in landscaping or highway pavement health

- Q:What are the advantages of using geogrids in construction projects?

- Geogrids offer several advantages in construction projects. Firstly, they provide reinforcement to the soil, enhancing its stability and load-bearing capacity. This allows for the construction of structures on weak or challenging soils that would otherwise require expensive excavation or additional materials. Additionally, geogrids help in preventing soil erosion by providing a barrier against the movement of soil particles, reducing the need for costly erosion control measures. Moreover, these grids are lightweight, making them easy to handle and install, saving time and labor costs during construction. Lastly, geogrids have a long lifespan and are resistant to chemical degradation, ensuring their effectiveness and durability over time. Overall, geogrids offer a cost-effective and sustainable solution for improving the performance and longevity of construction projects.

- Q:Are geogrids suitable for reinforcement of airport runways?

- Yes, geogrids are suitable for the reinforcement of airport runways. Geogrids are high-strength materials that can effectively distribute loads and provide stability to the runway surface. They have been extensively used in civil engineering projects, including airport runway construction, to enhance the strength and durability of the pavement structure. Geogrids help to minimize rutting, cracking, and other forms of distress, improving the overall performance and longevity of airport runways.

- Q:Are geogrids suitable for use in mechanically stabilized bridge abutments?

- Yes, geogrids are suitable for use in mechanically stabilized bridge abutments. Geogrids are commonly used in civil engineering projects to provide reinforcement and stability to soil structures. In the case of bridge abutments, geogrids can be incorporated into the backfill material to enhance its strength and prevent excessive settlement. By distributing loads and improving soil retention, geogrids help increase the overall stability and longevity of bridge abutments.

- Q:How to distinguish the vertical and horizontal geogrid

- Generally do not distinguish between vertical and horizontal

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Coated Polyester Geogrid Warp for Railway and Road

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords