POLYURETHANE FOAM sandwich panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Detailed Product Description

1. Heat and sound insulation. Temperature suitable for PU ranges from -200 centigrade to

150 centigrade.

2. Good chemical resistance, waterproof, anti-corrosion, insect-free etc.

3. Advanced Tech: Automatic rolling machines make the whole process of manufacture

effective.

4. Energy conservation, environmental protection, economical, heat insulting,

good structure,

easy-doing construction

5. Light weight enough to reduce building expense.

6. Time can be saved on a building project due to the simple installation

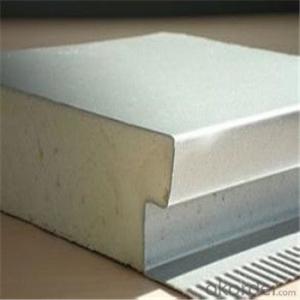

PU Sandwich panel (Polyurethane sandwiched panel )is composed of 2 layers of weather-proof colored steel sheets and jetted the hard forms of polyurethane between 2 layers which feature fireproof materials.

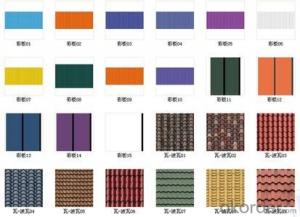

It is suitable for the various roofs and walls referring to the large-size factory buildings, storages, exhibition halls, gymnasiums, freezing stores, purifications workshops, etc, which features

temp-keeping, heat insulation, weight-bearing, weatherproof with the rich colorfulness and good appearance.

PU insulation sandwich panel

PU board adopts quality raw material from BASF which guarantees the qualtiy of foamed boards.

The board is formed in one time by pressure injection machine with color steel sheet or stainless steel sheet on both sides.

The polyurethane inside is spread evenly which guarantees a high efficiency in thermal insulation and lowers cold

consumption, thus, the customers operation cost is

pu panel sandwich

PU Sandwich Panel(Width 1000mm,100mm)

1, the quality of light weight per square meter of less than 24kg, can reduce the cost of the structure.

2, quick installation of light weight, splicing, installation and can be arbitrarily cutting characteristics, determine its

installation is simple, can improve efficiency, save the time.

3, fire, Caigang composite plate core surface materials and insulation materials for the non-fuel or burning material, can meet the requirements for fire protection.

4, refractory, with a special coating color steel plate and the new 10-15 years, after every ten years spraying anti-corrosion coating, sheet life over 35 years

5, beautiful, pressure plate clear lines of dozens of kinds of colors, can be matched with any style of the building takes

6, insulation insulation material commonly used are: rock wool glass fiber, cotton, polystyrene, polyurethane, low thermal

conductivity, good thermal insulation effect.

7, environmental noise prevention, composite board insulation strength up to 40-50 dB, is very effective sound insulation materials.

8, strong plasticity sheet steel can be cut, enough to meet the special design needs.

9, high strength with high strength steel plate as a substrate, the tensile strength of 5600 ( kg / cm2 ), plus on the most advanced design and roll forming, and has excellent structural properties

Applications:

1) sandwich panel used in large industrial plants, warehouses, supermarkets, hospitals, stadiums, cold storage, activities

room, buildings plus layer, clean workshop and heat insulation fire place.

2) sandwich plate appearance, bright color, good overall effect, it sets the bearing, thermal insulation, fireproof, waterproof

in one, and no two decoration, is a widely used, especially in the construction site of the temporary facilities such as office,

warehouse, walls, but also embodies the modern construction site civilization construction,

3) in the fast installation and put into use, the assembly and disassembly, material turnover multiplexing index, have

obvious advantages, greatly reducing the construction site temporary facilities, will be indispensable new lightweight

construction materials

This kind of pu sandwich panel has characters as follows:

Material:

1. steel strip:up/bottom 0.3- 1.2mm colourcoated steel panel/zinc plate,hot galvanized plate/stainless steel plate

2. core material: density of PU:30-80kg/m3

Specification:

1.T he applicable width of interface;950mm,1150mm

2. thichness:40mm-250mm

3. no length limit.

product perfomance: light and durable,easy to install, large usage

Fire-resistance rating:B

Usage: This kind of sandwich panel can be used in steel structure workshop,easy building and air clean room as walls

,ceilings. Especially for cold storage

- Q:How does the wall rock wool sandwich panel be installed?

- the basis for the preparation (the relevant laws and regulations, standards, construction drawings, computing software, etc

- Q:How the exterior of the house is made of rock wool color steel sandwich panels

- Seek the name of the maintenance tool for the vehicle maintenance and the figure (all)

- Q:Are sandwich panels suitable for food kiosks?

- Sandwich panels are indeed appropriate for food kiosks. They have gained significant popularity in the construction industry due to their durability, insulation properties, and ease of installation. These panels consist of two external layers, typically constructed from metal, and a core material, such as polyurethane foam or rockwool, which offers outstanding thermal insulation. To meet food safety regulations, food kiosks necessitate a hygienic and clean atmosphere. Sandwich panels provide a smooth, non-porous surface that is simple to clean and maintain, making them an ideal choice for food kiosks. Furthermore, these panels offer thermal insulation, helping to maintain the appropriate temperature for storing and serving food, regardless of the climate. In addition, sandwich panels are lightweight, facilitating effortless transportation and assembly. This allows for quick setup and relocation if necessary. Moreover, they possess remarkable structural strength, ensuring stability and security for the kiosk. All in all, due to their durability, insulation properties, hygienic surfaces, and ease of installation, sandwich panels are a suitable option for food kiosks.

- Q:Color steel tile and Caigang sandwich board What is the difference between the use of what is the difference

- Color steel room is a color steel composite panels (also known as Caigang sandwich panels) for the wall to light steel structure for the skeleton built. The color galvanized steel coating to maintain a period of 10-15 years, so the theoretical life can be more than 10-15 years, but also with the environment, the use of materials, quality and maintenance methods.

- Q:Color steel room life in general how many years

- The price with the upper and lower color plate thickness, polystyrene bulk density, there are regional differences are related. Specifically you can call the local color steel factory.

- Q:Can the foam sandwich be used as a cleaning plate?

- According to the "construction of fasteners steel scaffolding safety technical specifications" JGJ

- Q:Color steel sandwich board on the price of how much?

- Solid wood particle board moisture-proof effect than the wood sandwich board moisture-proof effect is better than the solid wood particle board and wood sandwich board difference . solid wood particle board, is made of wood or other lignocellulosic material, after the application of adhesive Heat and pressure under the action of synthetic wood-based panel. Solid wood particle board as a new, high-grade environmentally friendly substrate. Solid wood particle plate inside the cross-scattered structure of the granular. So the nail force is good, you can nail round nails, screws. These machinability is significantly better than MDF. . solid wood particle density is higher, the board of wood fiber particles larger, more to retain the nature of natural wood, in the use of solid wood particles on the board content is generally less than 5%, better environmental protection. Solid wood grain plate warp deformation small, stable size, good, high strength, good stiffness, hanging heavy clothing is not easy to bend. At present in the European furniture market, the use of wood-based panel is also solid wood particle board. . wood sandwich panels inside and outside the two sides for the glass plate, sandwich layer waterproof plywood, the German vacuum technology from high pressure compound. Sandwich panel surface smooth, dirt can be easily removed, the entire panel colorful, with excellent light-blocking. . fiberglass plate surface has a layer of excellent performance gel coat, the atmosphere, water and the general concentration of acid, alkali, salt and other media has a good chemical stability; surface finish, excellent light retention, no discoloration, corrosion resistance , Anti-sun, anti-aging. The main application areas: dry cargo compartment, large span structure roof, wall, purification plant, high profile portfolio housing, container rooms and so on.

- Q:Are sandwich panels suitable for train stations?

- Yes, sandwich panels are suitable for train stations. They are lightweight, strong, and provide excellent insulation properties. Additionally, sandwich panels can be easily installed and offer a wide range of design options, making them a practical and efficient choice for train station construction.

- Q:Can sandwich panels be used for ticket booths?

- Ticket booths can indeed utilize sandwich panels. Composed of two slim outer layers and a thermal insulating core material, sandwich panels possess a reputation for their robustness, longevity, and energy efficiency. These characteristics render them an excellent selection for diverse construction purposes, including ticket booths. By offering insulation against extreme temperatures, reducing noise, and providing fire resistance, sandwich panels offer essential attributes for ticket booths. Furthermore, their lightweight nature allows for effortless transportation and installation. They can be tailor-made to accommodate specific design specifications and require minimal maintenance. Consequently, sandwich panels emerge as a fitting and pragmatic choice for ticket booths.

- Q:Will the use of color steel sandwich panels ceiling package package how much money a square? M14 round steel to do hanging bars, 950 sandwich panels, the main bone 160 * 60 * 20 * 2.5 C steel Is the workshop ceiling, I should quote how much appropriate,

- What are the sub-items of the general project that should be prepared for the special safety program? What should be included in the special programming? The following dangerous parts of the sub-sub-projects and temporary electricity equipment in 5 and above or the total capacity of equipment in the 50kW and above the construction site of temporary electricity construction

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

POLYURETHANE FOAM sandwich panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords