On-Grid Inverter With Energy Storage 2000W

- Loading Port:

- Shenzhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Unit pc

- Supply Capability:

- 8000 Units/month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of On-Grid Inverter With Energy Storage 2000W

1.Pure sine wave output

2.Microprocessor controlled to guarantee stable charging system

3.Multiple operations: Grid tie, Off grid, and grid tie with backup

4.Built-in MPPT solar charger

5.LCD display panel for comprehensive information

6.Multiple communication

7.Green substitution for generators

8.User adjustable charging current up to 25A

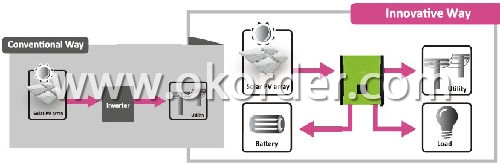

Feed-in is not only choice

In comparison with conventional grid-tie inverter, CNBM hybrid inverter is able to not only feed-in power to grid but also store solar power to battery for future usage and directly power to the loads.

Save money by discharging battery for self-consumption first

CNBM hybrid inverter can save money by using battery energy first when PV energy is low. Until battery energy is low, CNBM will extract AC power from the grid.

Power backup when AC failed

CNBM hybrid inverter can operate as an off-grid inverter to provide continuous power even without the grid.

It's perfect power solution for remote regions or temporary AC power source such as camping or flea market.

Datasheet of On-Grid Inverter With Energy Storage 2000W

MODEL | CNBM-H 2KW | CNBM-H 3KW |

RATED POWER | 2000W | 3000W |

GRID-TIE OPERATION | ||

PV INPUT (DC) | ||

Maximum DC power | 2250W | 3200W |

Nominal DC voltage / Maximum DC voltage | 300 VDC / 350VDC | 360 VDC / 500VDC |

Start voltage / Initial Feeding Voltage | 80 VDC / 120VDC | 116 VDC / 150 VDC |

MPP voltage range | 150 VDC ~ 320 VDC | 250 VDC ~ 450 VDC |

Number of MPP Trackers / Max. input current | 1 / 1×15A | 1 / 1×13A |

GRID OUTPUT (AC) | ||

Nominal Output Voltage | 101/110/120/127 VAC | 208/220/230/240 VAC |

Output Voltage Range | 88 - 127 VAC | 184 – 264.5 VAC |

Nominal Output Current | 18 A | 13.1 A |

Power Factor | > 0.99 | |

EFFICIENCY | ||

Maximum Conversion Efficiency (DC/AC) | 95% | 96% |

European Efficiency@ Vnominal | 94% | 95% |

OFF-GRID OPERATION | ||

AC INPUT | ||

AC Startup Voltage / Auto Restart Voltage | 60 - 70 VAC / 85VAC | 120 - 140 VAC / 180VAC |

Acceptable Input Voltage Range | 85 - 130 VAC | 170 - 280 VAC |

Maximum AC Input Current | 30A | 25A |

PV INPUT (DC) | ||

Maximum DC voltage | 350 VAC | 500 VAC |

MPP Voltage Range | 150 VAC ~ 320 VDC | 250 VAC ~ 450 VDC |

Maximum Input Current | 1 / 1×15A | 1 / 1×13A |

BATTERY MODE OUTPUT (AC) | ||

Nominal Output Voltage | 101/110/120/127 VAC | 208/220/230/240 VAC |

Output Frequency | 50 Hz / 60 Hz (auto sensing) | |

Output Waveform | Pure sine wave | |

Efficiency (DC to AC) | 90% | 93% |

HYBRID OPERATION | ||

PV INPUT (DC) | ||

Nominal DC voltage / Maximum DC voltage | 300 VDC / 350VDC | 360 VDC / 500VDC |

Start voltage / Initial Feeding Voltage | 80 VDC / 120VDC | 116 VDC / 150 VDC |

MPP voltage range | 150 VDC ~ 320 VDC | 250 VDC ~ 450 VDC |

Maximum Input Current | 1 / 1×15A | 1 / 1×13A |

GRID OUTPUT (AC) | ||

Nominal Output Voltage | 101/110/120/127 VAC | 208/220/230/240 VAC |

Output Voltage Range | 88 - 127 VAC | 184 – 264.5 VAC |

Nominal Output Current | 18 A | 13.1 A |

AC INPUT | ||

AC Startup Voltage / Auto Restart Voltage | 60 - 70 VAC / 85VAC | 120 - 140 VAC / 180VAC |

Acceptable Input Voltage Range | 85 - 130 VAC | 170 - 280 VAC |

Maximum AC Input Current | 30A | 25A |

BATTERY MODE OUTPUT (AC) | ||

Nominal Output Voltage | 101/110/120/127 VAC | 208/220/230/240 VAC |

Efficiency (DC to AC) | 90% | 93% |

BATTERY & CHARGER | ||

Nominal DC Voltage | 48 VDC | |

Maximum Charging Current | 25A | |

GENERAL | ||

PHYSICAL | ||

Dimension, D X W X H (mm) | 420 x 415 x 170 | |

Net Weight (kgs) | 15.5 | |

INTERFACE | ||

Communication Port | RS-232 / USB | |

Intelligent Slot | Optional SNMP, Modbus, and AS400 cards available | |

ENVIRONMENT | ||

Humidity | 0 ~ 90% RH (No condensing) | |

Operating Temperature | 0 to 40°C | |

Altitude | 0 ~ 1000 m | |

COMPLIANCE | ||

Standard | CE, VDE 0126-1-1,VDE-AR-N 4105 | |

- Q:Can a solar inverter be used with a solar-powered healthcare system?

- Yes, a solar inverter can be used with a solar-powered healthcare system. A solar inverter is responsible for converting the direct current (DC) generated by solar panels into alternating current (AC) that can be used to power various appliances and systems, including healthcare equipment. By integrating a solar inverter into a solar-powered healthcare system, the generated solar energy can be efficiently utilized to run medical devices and provide reliable electricity for critical healthcare services.

- Q:Can a solar inverter be used in systems with different module types?

- Yes, a solar inverter can be used in systems with different module types. Solar inverters are designed to convert the direct current (DC) generated by solar panels into alternating current (AC) that can be used to power electrical devices. They are compatible with various module types, such as monocrystalline, polycrystalline, and thin-film solar panels, allowing them to be used in diverse solar energy systems.

- Q:Can a solar inverter be connected to a battery storage system?

- Yes, a solar inverter can be connected to a battery storage system. In fact, this is a common setup in many residential and commercial solar installations. The solar inverter is responsible for converting the direct current (DC) generated by the solar panels into alternating current (AC) that can be used to power electrical appliances. By connecting a battery storage system to the solar inverter, excess energy generated by the solar panels can be stored in the batteries for later use, such as during periods of low sunlight or during power outages. This allows for greater energy independence and the ability to maximize the utilization of solar energy.

- Q:Can a solar inverter be used in a solar-powered air conditioning system?

- Yes, a solar inverter can be used in a solar-powered air conditioning system. A solar inverter converts the direct current (DC) produced by solar panels into alternating current (AC), which is required to power most appliances including air conditioning units. By using a solar inverter, the solar energy generated by the panels can be efficiently utilized to run the air conditioning system, reducing reliance on the electrical grid and lowering energy costs.

- Q:Can a solar inverter be used with a wireless communication system?

- Yes, a solar inverter can be used with a wireless communication system. In fact, many modern solar inverters are designed with built-in wireless communication capabilities to allow for monitoring and control of the system remotely. This enables users to access real-time data, adjust settings, and receive notifications about the performance of their solar power system through a wireless connection, such as Wi-Fi or cellular networks.

- Q:How does a solar inverter prevent reverse current flow?

- A solar inverter prevents reverse current flow by using built-in diodes that act as one-way valves, allowing electricity to flow only in the desired direction from the solar panels to the grid or battery system.

- Q:How does a solar inverter handle power export limitations imposed by the grid?

- A solar inverter handles power export limitations imposed by the grid through a process known as grid-tied or utility interactive operation. It continuously monitors the grid's voltage and frequency, adjusting the power output of the solar system accordingly. If the grid is unable to accept additional power due to export limitations, the inverter will reduce the output of the solar system to ensure compliance with the grid's requirements. This allows for a smooth and safe integration of solar power into the grid, preventing any potential disruptions or overloading.

- Q:Can a solar inverter be used in systems with different module efficiencies?

- Yes, a solar inverter can be used in systems with different module efficiencies. The solar inverter is designed to convert the DC electricity produced by the solar modules into AC electricity that can be used in the electrical grid or to power appliances. It does not depend on the module efficiency, but rather on the DC voltage and current produced by the modules. Therefore, as long as the DC output of the modules falls within the specifications of the solar inverter, it can be used regardless of the module efficiencies.

- Q:How does the efficiency of a solar inverter affect the overall system performance?

- The efficiency of a solar inverter plays a crucial role in determining the overall performance of a solar system. A higher efficiency inverter converts a greater percentage of the energy generated by the solar panels into usable electricity. This means that less energy is lost as heat, resulting in more electricity being available for consumption. A more efficient inverter translates into increased energy production, reduced reliance on grid power, and ultimately, higher cost savings. Additionally, a highly efficient inverter enhances the stability and reliability of the system, ensuring optimal performance and longevity.

- Q:What is the typical installation process for a solar inverter?

- The typical installation process for a solar inverter involves several steps. First, the inverter is mounted in a suitable location, usually close to the solar panels and near the electrical service panel. Then, the DC input wires from the solar panels are connected to the DC input terminals on the inverter. The AC output terminals of the inverter are then connected to the electrical service panel, allowing the generated electricity to be fed into the grid or used by the household. Finally, the inverter is connected to a monitoring system, which enables the user to track the performance and energy production of the solar system. It is important to note that the installation process may vary depending on the specific inverter model and the local electrical codes and regulations.

1. Manufacturer Overview |

|

|---|---|

| Location | Shenzhen,China |

| Year Established | 2010 |

| Annual Output Value | 50 million USD |

| Main Markets | Australia, Euro, America, China. |

| Company Certifications | CE, VDE-AR-N4105, FCC,ETL,CEC,CEI 0-21,G83,G59,SAA,CGC |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shenzhen, Guangzhou, Hongkong |

| Export Percentage | 60% |

| No.of Employees in Trade Department | 260 |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 500-1000 |

| No. of Production Lines | 8 |

| Contract Manufacturing | None |

| Product Price Range | 300-40000 USD |

Send your message to us

On-Grid Inverter With Energy Storage 2000W

- Loading Port:

- Shenzhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Unit pc

- Supply Capability:

- 8000 Units/month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords