Microporous Insulation Board, Heat Insulation materials for Ladle

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Micropore Insulation Board ,Heat Insulation materials

| Type: | Other Heat Insulation Materials | Place of Origin: | China (Mainland) | Brand Name: | |

| Model Number: | M5100 | service temperature, max.: | 1150 C | Thermal conductivity, @800 C: | 0.035 W/m.K |

| typical density: | 280 kgs/m3 |

Packaging & Delivery

| Packaging Details: | wooden cases |

| Delivery Detail: | 10 days |

Product Description

M5100 Panel is rigid finishing from microporous technology , with opcified blend of filament reinforced fumed silica, which provides a superb thermal performance.

It is an ideal back-up insulation for various industry where the high temperature is needed, with a long time exposure of 1150 °C at highest.

M5100 Panel ---Various coverings : Naked Panels, Aluminium Foil covering, E-class Fibre Cloth Covering, Fibre Paper covering.

M5100 Panel—Four Grades available : 850 , 1000, 1100, 1200

Properties & Advantages

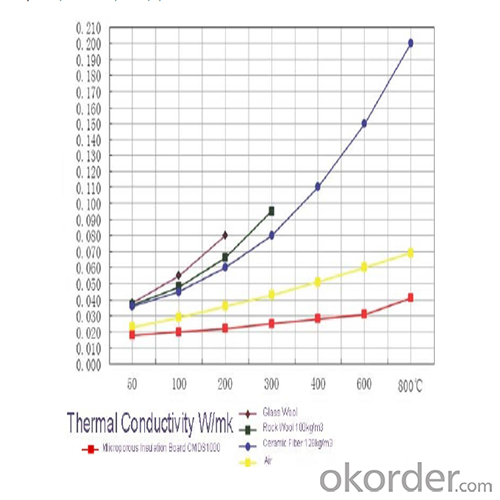

Extremely low thermal conductivity

High thermal stability

High compressive strength

No harmful respirable fibres

Free of organic binders

Environmentally friendly

Resistant to most chemicals

Non combustible

Easy to handle

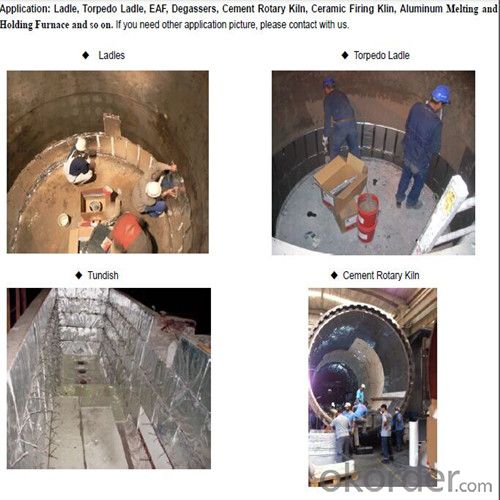

Typical Applications

Back-up insulation in industrial furnaces

Fuel cells (SOFC)

Thermal Batteries

Aluminium industry ( launders,Smelter.etc. )

Glass & ceramics industry

Petrochemical industry (cracking furnace, reformer)

Black box & VDR (Voyage Data Recorder)

Data loggers

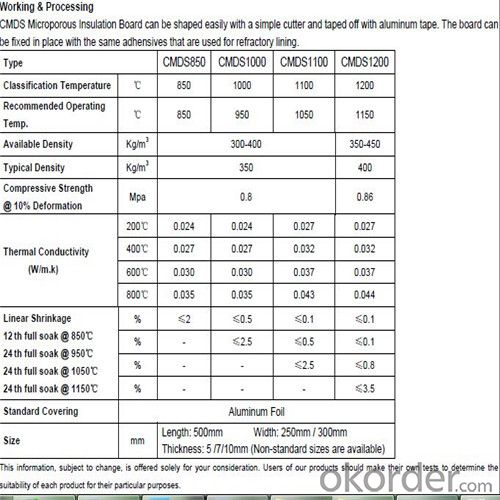

Working & Processing

M5100 can be shaped both manually and with stationary wood processing machinery. They can be cut, sawn, drilled and punched. The boards can be fixed in place with glue or by mechanical means such as anchors, pins and clips.

Technical Data for for Micropore Insulation Board ,Heat Insulation materials

| Description | MISSION STD Panel M5100 | ||||

| Classification Temperature | 0C | 850 | 1000 | 1100/1100S | 1200/1200S |

| Long time Exposure | 850 | 950 | 1050/1000 | 1150/1100 | |

| Nominal Density | [kg/m3] | 260-280 | 260-280 | 400-450 | 450-550 |

| Typical Density | 280 | 280 | 450 | 500 | |

| Compression Strength | [MPa] | 0.32 | 0.32 | 0.72 | 0.8 |

| @10% deformation (ASTM C-165) | |||||

| Thermal Conductivity | |||||

| 200 0C | W/m.K | 0.022 | 0.022 | 0.024 0.028 | 0.027 0.029 |

| 400 0C | W/m.K | 0.025 | 0.025 | 0.028 0.032 | 0.032 0.035 |

| 600 0C | W/m.K | 0.028 | 0.028 | 0.032 0.038 | 0.037 0.042 |

| 800 0C | W/m.K | 0.033 | 0.033 | 0.035 0.045 | 0.043 0.046 |

| Specific Heat Capacity | |||||

| 200 0C | [KJ/Kg K] | 0.85 | 0.86 | 0.86 | 0.89 |

| 400 0C | [KJ/Kg K] | 0.95 | 0.96 | 0.97 | 0.99 |

| 600 0C | [KJ/Kg K] | 1.02 | 1.03 | 1.04 | 1.05 |

| 800 0C | [KJ/Kg K] | 1.07 | 1.08 | 1.08 | 1.08 |

| Linear Shrinkage | |||||

| 12h full soak @ 850 0C | % | ≤2 | ≤0.5 | ≤0.1 ≤0.1 | ≤0.1 ≤0.1 |

| 24h full soak @ 950 0C | - - - | ≤2.5 | ≤0.5 ≤0.1 | ≤0.5 ≤0.5 | |

| 24h full soak @ 1050 0C | - - - | - - - | ≤2.5 - - - | ≤2.5 ≤2.5 | |

| 24h full soak @ 1150 0C | - - - | - - - | - - - - - - | ≤3.5 - - - | |

Standard Dimension:

1000(900)×600(500)×5-20mm

We can also manufacture the special dimensions as customers need.

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Thanks for your coming in,if there is any question,I will be glad to help you.

- Q:Can glass fiber textile be used in protective helmets?

- Yes, glass fiber textile can be used in protective helmets. Glass fiber is a lightweight and durable material that can provide excellent strength and impact resistance. It is commonly used in the construction of helmets to enhance their protective capabilities. The woven glass fibers create a strong and rigid structure that can effectively absorb and distribute impact forces, reducing the risk of head injuries. Furthermore, glass fiber textiles can also provide insulation and heat resistance, making them suitable for helmets used in high-temperature environments. Overall, the use of glass fiber textile in protective helmets is a reliable choice for ensuring safety and protection.

- Q:What are the different techniques for joining glass fiber textile?

- Glass fiber textiles can be joined using various techniques, each with its own advantages and applications. Some commonly used techniques are: 1. Traditional sewing: By utilizing a needle and thread, glass fiber textiles can be stitched together. This versatile technique allows for flexibility and simple repair, making it ideal for applications that require frequent adjustments or disassembly. 2. Adhesive bonding: Two or more glass fiber textiles can be bonded together using adhesive. This technique creates a strong and durable bond, making it suitable for applications that demand high strength and rigidity. However, it may not be suitable for high-temperature environments or areas with chemicals or moisture. 3. Heat sealing: Heat is applied to the fibers to melt and fuse them together in heat sealing. This technique results in a robust and permanent bond, making it suitable for applications that require resistance to wear and tear and high strength. 4. Ultrasonic bonding: High-frequency vibrations generate heat, which then melts the glass fibers and bonds them in ultrasonic bonding. This fast and efficient technique is ideal for high-volume production and provides a reliable bond for applications that require durability and strength. 5. Mechanical fasteners: Glass fiber textiles can also be joined using mechanical fasteners such as screws, bolts, and clips. This technique allows for easy assembly and disassembly, making it suitable for applications that require frequent adjustments or repairs. Mechanical fasteners provide a strong and dependable bond for applications that require high strength and rigidity. In conclusion, the choice of joining technique for glass fiber textiles depends on specific application requirements, such as strength, durability, flexibility, and ease of assembly or disassembly. Considering these factors is crucial in selecting the most appropriate technique to ensure optimal performance and longevity of the joined textiles.

- Q:Can glass fiber textiles be embroidered?

- Yes, glass fiber textiles can be embroidered. Glass fiber textiles, also known as fiberglass, are flexible and can be woven into a fabric-like material. This makes them suitable for embroidery techniques such as hand embroidery or machine embroidery. However, it is important to consider that glass fiber textiles are more rigid and less pliable than traditional fabrics like cotton or silk, which may affect the embroidery process. Additionally, due to the nature of glass fiber, special needles and threads designed for working with this material may be necessary to achieve the desired results.

- Q:Can glass fiber textiles be used in the production of sporting equipment?

- Yes, glass fiber textiles can be used in the production of sporting equipment. Glass fiber textiles, also known as fiberglass textiles, are made from fine strands of glass that are woven together to create a fabric-like material. This material is lightweight, strong, and flexible, making it ideal for use in sporting equipment. One common use of glass fiber textiles in sporting equipment is in the construction of tennis rackets. The glass fibers provide added strength and stiffness to the racket, allowing players to generate more power and control in their shots. Additionally, the flexibility of the glass fibers helps to absorb and dampen vibrations, reducing the risk of injury and improving comfort during gameplay. Glass fiber textiles are also used in the production of hockey sticks. The strong and lightweight nature of the material allows for greater stick speed and maneuverability on the ice. The flexibility of the glass fibers also helps to enhance the shot power and accuracy, making them a popular choice among hockey players. Furthermore, glass fiber textiles can be found in the construction of various protective gear for sports such as helmets, shin guards, and body armor. The high strength-to-weight ratio of glass fibers provides excellent impact resistance, ensuring the safety of athletes during intense physical activities. In conclusion, glass fiber textiles have proven to be a valuable material in the production of sporting equipment. Their lightweight, strong, and flexible properties make them an excellent choice for enhancing performance and safety in various sports.

- Q:Polyester fiber fabric clothes will cross it out

- No, polyester fiber is actually polyester.Polyester fiber generally refers to polyester fiberAdvantages: fabric crisp, smooth, bright color. Pregnant bone elastic, moisture absorption, good ventilation, smooth surface, there is a certain waterproof function.

- Q:How does glass fiber textile perform in terms of static electricity resistance?

- Glass fiber textile has excellent static electricity resistance. Due to its non-conductive properties, it does not accumulate static electricity easily, making it a reliable choice in industries where static electricity control is crucial, such as electronics or cleanroom environments.

- Q:What is the melting point of glass fiber textiles?

- The melting point of glass fiber textiles may differ based on the specific composition and manufacturing process employed. In general, the melting point of glass fibers falls within the range of 1200 to 1600 degrees Celsius (or 2192 to 2912 degrees Fahrenheit). Nevertheless, it is crucial to bear in mind that glass fibers do not undergo melting in the same manner as other materials, such as metals or plastics. Instead, they undergo a process termed softening, in which the fibers lose their structural integrity and become flexible. This softening temperature is typically lower than the actual melting point, usually around 800 to 1000 degrees Celsius (or 1472 to 1832 degrees Fahrenheit).

- Q:Can glass fiber textiles be used in the production of outdoor furniture?

- Yes, glass fiber textiles can be used in the production of outdoor furniture. Glass fiber is a strong and durable material that is resistant to weather conditions such as rain, sunlight, and temperature fluctuations. It also has excellent resistance to corrosion, making it suitable for outdoor settings where furniture is exposed to moisture and other environmental factors. Additionally, glass fiber textiles are lightweight, making them easy to move and rearrange as needed. The material can be woven or molded into various shapes and designs, providing flexibility in creating different styles of outdoor furniture. Overall, glass fiber textiles are a practical and reliable choice for outdoor furniture production.

- Q:Are glass fiber textiles resistant to bacterial odors?

- Glass fiber textiles are known for their ability to resist bacterial odors. Due to their non-porous nature, bacteria and odor-causing microbes struggle to penetrate the surface of glass fiber. Moreover, manufacturers often incorporate anti-microbial agents into the production of glass fiber textiles, further bolstering their resistance to bacterial odors. As a result, glass fiber textiles are highly recommended for situations where odor control is crucial, such as in healthcare facilities or sports attire. Nevertheless, it is worth mentioning that the effectiveness of odor resistance may vary depending on the specific kind of glass fiber textile and the degree of anti-microbial treatment employed.

- Q:How do glass fiber textiles compare to natural fibers in terms of sustainability?

- Glass fiber textiles and natural fibers differ significantly in terms of sustainability. While natural fibers, such as cotton or hemp, are derived from renewable resources, glass fiber textiles are made from non-renewable materials like sand and limestone. The extraction and processing of these raw materials for glass fibers can have a substantial environmental impact, including energy consumption and greenhouse gas emissions. Additionally, the production of glass fiber textiles requires a considerable amount of energy and water, further contributing to their environmental footprint. On the other hand, natural fibers can be grown with minimal water and energy inputs, and their production often supports local agricultural communities and reduces the reliance on synthetic materials. Moreover, glass fiber textiles are not biodegradable, meaning they can persist in the environment for hundreds of years, contributing to waste accumulation and potential pollution. In contrast, natural fibers, being organic in nature, are generally biodegradable and can decompose naturally over time, minimizing their impact on landfills and ecosystems. However, it is important to note that the sustainability of glass fiber textiles can be improved through recycling and the use of more energy-efficient manufacturing processes. Recycling glass fibers can reduce the need for virgin materials and lower environmental impacts. Additionally, advancements in technology and production methods can help reduce the energy and water consumption associated with glass fiber production. In conclusion, while glass fiber textiles have certain advantages such as high strength and durability, they generally have a higher environmental impact compared to natural fibers in terms of sustainability. Natural fibers, on the other hand, are renewable, biodegradable, and require fewer resources for production. However, improvements in manufacturing practices and recycling efforts can enhance the sustainability of glass fiber textiles, making them a more environmentally friendly option in the future.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Microporous Insulation Board, Heat Insulation materials for Ladle

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords