Microporous Calcium Silicate Insulation Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Micropore Insulation Board ,Heat Insulation materials

| Type: | Other Heat Insulation Materials | Place of Origin: | China (Mainland) | Brand Name: | |

| Model Number: | HCS | Color: | white | Apparent Density: | 220 +/- 10% |

| Heat Conductivity: | 0.060 | Highest Working Temperature: | 1050 | Material: | Xonotlite and reinforced glass fiber |

Packaging & Delivery

| Packaging Details: | Standard Fumigation Wooden pallet or Carton Package with Plastic Sheet inside |

| Delivery Detail: | Generally within 2 weeks after receipt of deposit |

Specifications

Microporous calcium silicate insulation board

experienced manufacturer

Size:1000*600mm,600*150mm

ISO9001:2008

Microporous calcium silicate insulation board

It is mixed with Xonotlite and reinforced glass fibre with high service temp. (1050 celsius),good heat insulation, low bulk density, high strength, good durability and so on.

Product characteristics:

² Good durability, can bear high temperature within the limit of continuous heat load,

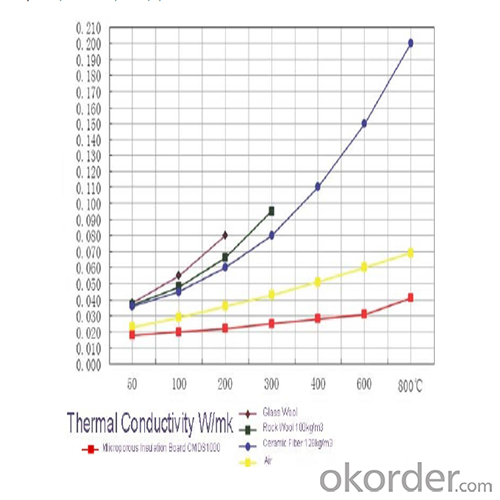

² Low thermal conductivity, in the whole range are used with unmatched adiabatic performance.

² Light weight, high strength. It is the highest in these hard thermal insulation products.

² Better durability, use for a long time without powder.

² Construction with ordinary carpenter applicability, tools can be optional cut products.

² Used safety, hygiene. Excluding asbestos, sulfur, chlorine such poisonous substances.

² Fear water, but after drying also can be used.

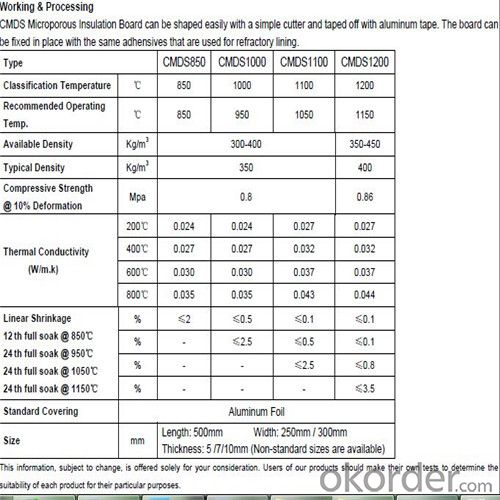

HCS Physical Performance Index

Items | Unit | HCS-170 | HCS-220 | HCS-270 |

Bulk Density | Kg/m3 | 170(±10%) | 220(±10%) | 270(±10%) |

Pressure Strength | MPa | ≥0.40 | ≥0.50 | ≥0.60 |

Flexural Strength | MPa | ≥0.30 | ≥0.35 | ≥0.40 |

Thermal Conductive | W/m.k | ≤0.048 +0.00011t | ≤0.050 +0.00011t | ≤0.056 +0.00011t |

Temp. limit | degrees | 1000 | 1050 | 1050 |

Linear Shrinkage | % | ≤1.50 (1000,3hrs) | ≤1.50 (1000,3hrs) | ≤1.50 (1000,3hrs) |

Block Sizes and Dimensional Tolerances

Length(±3mm) | Width(±3mm) | Thickness(+2mm,—1.5mm) |

610 | 303,300,150 | 25—140 |

600 | 300 | 25—140 |

400 | 250 | 25—140 |

1000 | 500 | 25—140 |

1200 | 600 | 25—140 |

We also supply special size and type.

Standard Dimension:

1000(900)×600(500)×5-20mm

We can also manufacture the special dimensions as customers need.

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Thanks for your coming in,if there is any question,I will be glad to help you.

- Q:Can glass fiber textiles be printed on?

- Yes, glass fiber textiles can be printed on. Glass fibers can be coated with various printable materials like inks, dyes, or pigments to create designs or patterns on the textile surface. This printing process allows for customization and adds aesthetic value to the glass fiber textiles.

- Q:Are glass fiber textiles resistant to shrinkage?

- Yes, glass fiber textiles are resistant to shrinkage.

- Q:How do glass fiber textiles perform in terms of electrical conductivity?

- Glass fiber textiles are known for their excellent electrical insulation properties, meaning they have very low electrical conductivity.

- Q:How do glass fiber textiles contribute to moisture resistance?

- Glass fiber textiles contribute to moisture resistance through their inherent properties. Glass fibers are made from a non-absorbent material, meaning they do not readily soak up or retain moisture. This helps to prevent water from seeping through the textile and reaching the underlying materials or surfaces. Additionally, glass fiber textiles are often woven or knitted into a tight and dense structure, which creates a barrier against moisture. The interlocking fibers form a physical barrier that prevents water molecules from passing through, thereby enhancing the moisture resistance of the textile. Moreover, glass fibers are highly resistant to mold and mildew growth, which can be triggered by moisture. This resistance is due to the inorganic nature of glass fibers, as mold and mildew typically thrive on organic materials. By inhibiting the growth of these microorganisms, glass fiber textiles help to maintain a dry and moisture-free environment. Furthermore, glass fiber textiles can be treated with water-repellent coatings or finishes to enhance their moisture resistance. These coatings create a hydrophobic surface, causing water to bead up and roll off the textile rather than being absorbed. This additional layer of protection further improves the moisture resistance of glass fiber textiles. In summary, glass fiber textiles contribute to moisture resistance through their non-absorbent nature, dense structure, resistance to mold and mildew, and the potential for water-repellent coatings. These properties make glass fiber textiles an excellent choice for applications where moisture resistance is crucial, such as in outdoor clothing, upholstery, or building materials.

- Q:How do glass fiber textiles affect the drape of fabrics?

- Glass fiber textiles, also known as fiberglass textiles, can significantly affect the drape of fabrics. Due to their inherent stiffness and rigidity, fabrics that incorporate glass fiber textiles tend to have a stiffer and less fluid drape compared to fabrics without such reinforcements. The presence of glass fiber textiles adds structural integrity and strength to the fabric, making it more resistant to stretching and sagging. This can be beneficial in certain applications where durability and shape retention are crucial, such as upholstery fabrics, outdoor textiles, and industrial fabrics. However, the stiffness of glass fibers can also limit the natural flow and movement of the fabric. Fabrics with glass fiber textiles may lack the softness and suppleness that is desirable in clothing and drapery fabrics. They may feel less comfortable against the skin and restrict the freedom of movement of the wearer. It is worth noting that the impact on drape will vary depending on the amount and type of glass fiber textiles used, as well as the overall fabric construction. For instance, fabrics with a higher concentration of glass fibers or fabrics where the fibers are tightly woven or bonded may exhibit a more pronounced effect on drape. In conclusion, glass fiber textiles have a significant impact on the drape of fabrics, resulting in a stiffer and less fluid drape. While this can be advantageous in terms of durability and shape retention, it may also compromise the comfort and natural movement of the fabric, making it less suitable for certain applications such as clothing and drapery.

- Q:How does the fiber length affect the properties of glass fiber textiles?

- The properties of glass fiber textiles are impacted by the length of their fibers. To begin with, longer fiber lengths generally result in stronger and more durable textiles. This is because the longer fibers interlock and bond within the fabric, increasing its tensile strength and making it more resistant to tearing or breaking when under stress. Additionally, longer fibers provide better flexibility and improved drapability to the fabric. They can be woven or knitted into complex patterns with greater ease, allowing the textile to be shaped and molded as required. This is especially important for applications where the fabric needs to conform to different shapes or be used in structural components. Moreover, longer fiber lengths enhance the thermal and electrical conductivity of glass fiber textiles. They provide a larger surface area for heat or electricity to transfer through the fabric. This is advantageous in applications where thermal insulation or electrical conductivity is necessary. However, it is important to consider the limitations of longer fiber lengths. They can make the textile stiffer and less comfortable to wear, reducing its suitability for clothing or soft furnishings. The longer fibers can also increase the weight of the fabric, making it less suitable for lightweight or high-performance applications. In conclusion, the choice of fiber length is crucial in determining the strength, durability, flexibility, thermal conductivity, and electrical conductivity of glass fiber textiles. It should be carefully considered based on the desired properties and specific requirements of the application.

- Q:What are the disadvantages of using glass fiber textiles?

- Glass fiber textiles come with a range of drawbacks. Firstly, their cost is generally higher compared to other textile materials due to the complex production process and specialized equipment required. This can be problematic for those on limited budgets. Secondly, glass fiber textiles are prone to breakage and brittleness. Despite being known for their strength and durability, they can easily sustain damage from external forces or impacts. This restricts their use in applications where flexibility or resistance to bending is crucial. Another disadvantage relates to the potential health risks associated with glass fibers. During manufacturing, tiny glass particles can become airborne and inhaled, posing a threat to workers' respiratory systems. Prolonged exposure to these fibers can result in lung diseases such as fibrosis or even lung cancer. Therefore, it is essential to take proper safety precautions, such as wearing protective masks, when working with glass fiber textiles. Furthermore, glass fiber textiles have poor resistance to high temperatures. They tend to lose their structural integrity and strength when exposed to extreme heat. This hinders their usability in industries like aerospace or automotive, where heat resistance is critical. Lastly, glass fiber textiles exhibit relatively low resistance to UV radiation. Prolonged exposure to sunlight can cause the fibers to degrade, leading to discoloration and weakened strength. This presents a significant drawback in applications where the textiles are exposed to outdoor conditions or direct sunlight. In conclusion, despite their strengths and durability, glass fiber textiles have several disadvantages to consider, including high cost, brittleness, potential health risks, poor heat resistance, and low resistance to UV radiation. These factors should be taken into account when deciding whether to utilize glass fiber textiles in different applications.

- Q:How to make a fishing boat with fiberglass cloth?

- If you use it, do not pay attention to too much, there is probably a can, in the mold to pull out the line on the line.

- Q:How do glass fiber textiles affect tactile comfort?

- Tactile comfort can be influenced by glass fiber textiles in various ways. On the one hand, these textiles can enhance comfort by offering a smooth and soft texture. Weaving or knitting the fibers into a fabric creates a gentle sensation against the skin, providing a pleasant and comfortable feeling. However, there are also drawbacks to consider when it comes to the tactile comfort of glass fiber textiles. If the fibers are not properly treated or the fabric is poorly constructed, they can be sharp and abrasive, causing discomfort and irritation upon direct contact with the skin. Moreover, the heat conductivity of glass fibers can make the fabric feel either cold or hot, depending on the surrounding temperature. In addition, glass fiber textiles have a tendency to trap moisture, which can adversely affect tactile comfort. The accumulation of moisture between the fibers creates a damp and clammy sensation, which can be uncomfortable for the wearer. This issue is particularly problematic in situations where effective moisture management is crucial, such as in sportswear or outdoor clothing. In conclusion, glass fiber textiles can have both positive and negative effects on tactile comfort. While they can offer a smooth and soft texture, they can also be sharp and abrasive if not properly treated. Furthermore, their heat conductivity and moisture trapping tendencies can negatively impact tactile comfort. Therefore, it is essential to carefully consider the specific characteristics and construction of glass fiber textiles when evaluating their influence on tactile comfort.

- Q:What are the environmental impacts of glass fiber textile production?

- The environmental impacts of glass fiber textile production include the consumption of large amounts of energy and water during the manufacturing process. Additionally, the production of glass fibers often involves the use of chemicals and resins that can be harmful to the environment if not properly managed. The disposal of waste materials generated during production can also pose a challenge, as glass fibers are not easily biodegradable. However, glass fiber textiles have a longer lifespan compared to other materials, which can reduce the overall environmental impact in terms of waste generation and resource consumption.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Microporous Calcium Silicate Insulation Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords