High Temperature Ceramic Rollers

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Alumina ceramic tube insulation

2.High quality: 1800C Max working temperature

3.Various sizes ceramic tube

Alumina Ceramic Roller Specifications

1. High workingh temperature roller, 1150C to 1300C.

2. Good roundness and straightness.

3. Large quantity in stock.

Alumina Ceramic Roller is the main products of Mission Ceramic. According to

working temperature we are mainly making 3 types alumina ceramic rollers.

MSCR-A: Al2O3 content, 75%, Max working temperature: 1300C,

MSCR-B: Al2O3 content, 73%, Max working temperature: 1250C,

MSCR-C: Al2O3 content, 71%, Max working temperature: 1200C.

Standard Diameter of Mission Alumina Ceramic Roller,

OD(mm) | 25 | 27 | 30 | 33.7 | 35 | 40 | 42 | 45 | 48 | 50 | 55 | 60 | 65 |

ID(mm) | 15 | 17 | 20 | 22.5 | 24 | 29 | 31 | 34.6 | 36.8 | 38.5 | 43.5 | 48 | 52.4 |

Other sized can be made according to your need.

Length can be cut to your need.

Advantage of Mission Alumina Ceramic Roller

Good thermal stability, good bending strength, Low porosity, low thermal expansion.

Good straightness, roundness.

Application of Mission Alumina Ceramic Roller,

Transformer and supporter of roller kiln.

Other thermal and abrasive application.

If you have any question, please contact with us. I believe you will like our products and service

It’s our mission to provide you high quality ceramic products!

- Q:What is the main role of fly ash added in concrete products?

- The rational use of fly ash in concrete, not only can replace part of cement, reduce the construction cost, but also because of its unique properties can be effectively used for the various requirements of the use of concrete, improve and enhance the performance of concrete.

- Q:What's the difference between white cement and ordinary cement?

- White portland cement as the raw meal with the proper components till the partial melting of the calcium silicate as the main ingredient, the iron content in clinker less addition of gypsum, white water ground made of rigid cementitious material. When grinding cement, allow limestone not to exceed 5% of the cement weight. White cement is mostly ornamental, and its manufacturing process is much better than ordinary cement. The gap is mainly used to hook white tiles, is generally not used in the wall, the reason is not high strength. It is available in the building materials market or decoration materials shop.

- Q:What is the maximum temperature at which the glass is cured?

- Glass is softened at a temperature of 600 degrees. When making glass, but ordinary alcohol lamp is enough to soften it. Glass is not crystal. The softening point of lead glass is 500 degrees. The main component of ordinary glass is CaO: Na2O: 6SiO2, which can be softened by fire. In addition to the ordinary glass, glass wire, alcohol burner 1000 degree glass has no definite melting point and freezing point, in softening products can be made into any shape, so there is no fixed melting point, clarification, fluoride special glass based raw materials, slightly higher than 1200 DEG C melting, but the softening point, as well as borate, limestone, mixed melt in glass kiln.

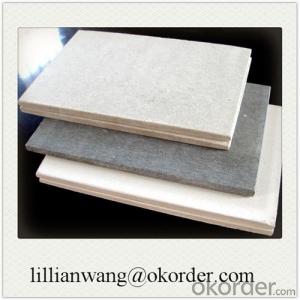

- Q:Which is better, asbestos free calcium silicate and aluminium silicate refractory fiber?

- The two are thermal insulation materials. Calcium silicate board strength, cheap, but the use of temperature is not high, the highest 1000 degrees.

- Q:What's the use of white portland cement?

- The typical feature of white cement is high whiteness, with bright color, generally used for a variety of architectural decoration materials, painting, sculpture, a typical floor, terrazzo, white cement can be used to produce white and colored concrete, is the largest cement production decoration.

- Q:What is the best price for the use of calcium silicate ceiling?

- Neither calcium silicate nor silicate boards are afraid of water because they are mixtures of gypsum and fiber.

- Q:What are the raw materials of cement products? What's the function?

- Water is necessary for the production of cement products, the role of water is to cement hydration. Generally, the water cement ratio of concrete is 0.40~0.65. If the water is too large, it will leave a hole in the concrete, which will affect the strength, density and durability of the concrete and even cause water leakage.

- Q:Calcium silicate board for house ceiling, 6mm or 8mm?

- The calcium silicate board will not have the above shortcomings, the thickness of 15mm if it is the calcium silicate board 4mm ceiling 600*600 thickness can reach the effect of the biggest advantages of mineral wool board, calcium silicate board also is not a burning fire, moisture absorption is very good, green building materials.

- Q:Cement is not silicate products

- So, we usually call cement as cementitious material - cement products

- Q:What is a building energy-saving materials?

- Heat insulation materials and insulation materials collectively referred to as thermal insulation materials.The commonly used thermal insulation material: mineral wool, rock wool, glass wool (in rock, slag as the main raw material, by high temperature melting, made by centrifugal methods such as cotton and thermosetting resin binder insulation products. ) foam plastics and porous polymers, expanded perlite and their products, calcium silicate insulation products, all kinds of composite insulation materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Temperature Ceramic Rollers

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords