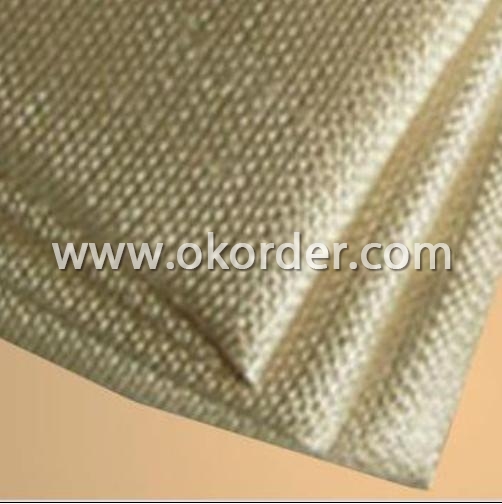

Heat Treated E- Glass Fiber Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 tons kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General infor of Heat Treated E- Glass Fiber Fabric

It is fiberglass cloth impregnated our special formulated Hi-temp. resistance solutions which provides short temperature resistance of 1000C degree and increased continuous temperature resistance temperature up to 750C degree.

This impregnation also increases the products’ abrasion resistance and adds to its ability to withstand direct flame.

Product Feature of Heat Treated E- Glass Fiber Fabric

Mat width ranges from 50mm-3120mm Uniform density ensures consistent fiberglass content and mechanical properties of the final products the mats feayure good mat integrity ,low fuzz,less material waste and small roll dia meter. Excellent flexibility ensures good moldability with no springback at sharp angles, fast and consistent wet-out speed in high dry and wet tensile strength and good transparency.

Product Application of Heat Treated E- Glass Fiber Fabric

Emulsion Chopped Strand Mat is mainly applied to unsaturated polyester ,viny ester and epoxyresins. The product is most widely used in hand lay-up process and also can be used in filament winding. compression molding and continuous laminating processes. The typical end products including various panels, boats,ba

- Q:Are glass fiber textiles suitable for sports apparel?

- Yes, glass fiber textiles are suitable for sports apparel. They offer excellent durability, moisture-wicking properties, and thermal insulation. Glass fiber textiles also have high strength-to-weight ratio and can provide effective protection against impacts. Additionally, they are resistant to UV radiation and have low water absorption, making them ideal for sports activities that involve exposure to the elements.

- Q:Can glass fiber textiles be used in soundproofing?

- Yes, glass fiber textiles can be used in soundproofing. Glass fiber textiles are known for their excellent sound-absorbing properties, making them an ideal material for soundproofing applications. They can effectively reduce the transmission of sound waves by absorbing and dissipating the energy. Glass fiber textiles can be used in various soundproofing applications such as wall panels, acoustic ceiling tiles, acoustic curtains, and insulation materials. They are capable of reducing the noise levels in a room by absorbing the sound waves and preventing them from bouncing off hard surfaces, thus creating a quieter environment. Additionally, glass fiber textiles are lightweight, easy to install, and provide thermal insulation as well, making them a versatile choice for soundproofing purposes.

- Q:Can glass fiber textiles be washed?

- Yes, glass fiber textiles can be washed.

- Q:Can glass fiber textiles be used in art?

- Yes, glass fiber textiles can be used in art. They offer unique qualities such as transparency, strength, and flexibility which make them suitable for various artistic applications. Artists can incorporate glass fiber textiles into sculptures, installations, or even use them as a canvas for painting or other forms of artistic expression.

- Q:Can glass fiber textiles be used in medical bandages or dressings?

- Yes, glass fiber textiles can be used in medical bandages or dressings. They are commonly used in wound care due to their high strength, durability, and ability to provide support and protection to the injured area. Additionally, glass fiber textiles have antimicrobial properties that can help prevent infections, making them suitable for medical applications.

- Q:Can glass fiber textiles be used in aerospace applications?

- Glass fiber textiles have numerous properties that make them ideal for use in aerospace applications. Firstly, their high strength-to-weight ratio is crucial in reducing the weight of aircraft, resulting in improved performance and cost savings. Secondly, glass fiber textiles can withstand extreme heat without compromising their structural integrity, making them suitable for use in components exposed to high temperatures, such as engine parts and exhaust systems. In addition, glass fiber textiles exhibit excellent resistance to corrosion and chemicals, which is essential in aerospace applications where materials are exposed to harsh environments, including high altitudes and various fluids and fuels. Moreover, glass fiber textiles possess outstanding electrical insulation properties, preventing interference with electronic systems, a critical factor in aerospace applications. Furthermore, their versatility allows for weaving into different forms, such as fabrics, mats, and tapes, enabling their use in a wide range of aerospace applications, including structural components, insulation, and composite materials. In conclusion, glass fiber textiles offer a viable solution for aerospace applications due to their high strength-to-weight ratio, impressive thermal properties, resistance to corrosion and chemicals, electrical insulation capabilities, and their ability to be woven into various forms.

- Q:Can glass fiber textile be used in wind turbine blades?

- Yes, glass fiber textile can be used in wind turbine blades. Glass fiber textiles are commonly used in the construction of wind turbine blades due to their high strength, lightweight nature, and excellent resistance to environmental elements. These properties make glass fiber textiles an ideal choice for manufacturing wind turbine blades, enabling them to efficiently harness wind energy for electricity generation.

- Q:Can glass fiber textiles be used in extreme temperatures?

- Indeed, extreme temperatures can be withstood by glass fiber textiles. The remarkable heat resistance of glass fiber renders it appropriate for utilization in a wide range of industries and applications that necessitate materials capable of enduring intense heat. Without compromising their structural integrity or functionality, glass fiber textiles can typically endure temperatures as elevated as 1000°C (1832°F). Consequently, they are exceptionally well-suited for deployment in tasks involving insulation, fireproofing, and protective garments within environments characterized by high temperatures. Furthermore, the exceptional thermal insulation properties possessed by glass fiber textiles further amplify their capacity to withstand extreme temperatures.

- Q:Can glass fiber textiles be used for filtration?

- Yes, glass fiber textiles can be used for filtration. Glass fibers have excellent filtration properties due to their high surface area and fine pore structure. They are commonly used in various filtration applications, such as air filters, water filters, and industrial filtration systems. Glass fiber textiles can effectively capture and remove particulate matter, dust, and other contaminants from fluids or gases, making them an ideal choice for filtration purposes. Additionally, glass fiber textiles are resistant to high temperatures, chemicals, and microorganisms, further enhancing their suitability for filtration applications.

- Q:Can glass fiber textiles be molded?

- Yes, glass fiber textiles can be molded. They can be shaped or formed into various designs and structures using molding techniques such as compression molding, injection molding, or vacuum infusion.

1. Manufacturer Overview |

|

|---|---|

| Location | Beijing, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 3 Million |

| Main Markets | North America;Southeast Asia ;Western Europe ;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjing |

| Export Percentage | 60% - 70% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | |

| Product Price Range | High; Average |

Send your message to us

Heat Treated E- Glass Fiber Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 tons kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords