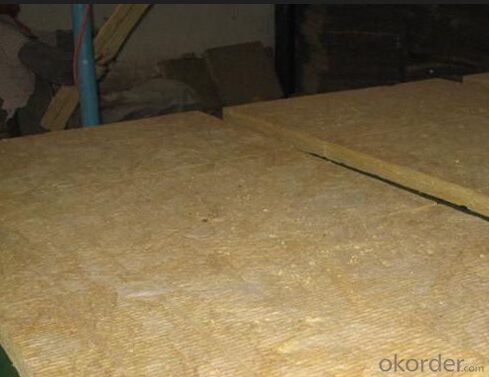

Heat Resistant Rock Wool Board CMAX

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal insulation rock wool boards

Thermal insulation rockwool boards is a board product with certain strength. The product is mainly used for fireproofing and sound absorption of partition walls and curtain walls, thermal insulation of roofs, retaining structures and geothermal systems as well as thermal insulation and fireproofing of industrial kilns, ovens, large sized tanks and vessels, etc

Thermal insulation rock wool boards is a board product with certain strength. The product is mainly used for fireproofing and sound absorption of partition walls and curtain walls, thermal insulation of roofs, retaining structures and geothermal systems as well as thermal insulation and fireproofing of industrial kilns, ovens, large sized tanks and vessels, etc.

Specifications

glass wool insulation without aluminum foil

professional factory

density: 10-72kg/m3

thickenss:25-200mm

AS/NZS48591 ,

rockwool(basalt):

length:1200mm

width:600mm

thickness:25-200,mm

density:40-200kg/m3

•Length: 5m-30m

• Width: 1200mm,600mm

• Thickness: 25mm-200mm

Item | Products | Density kg/m3 | Thickness | Size Length*width |

1 | Inorganic fibers spraying glass wool glassglass wool manufactory | 10 | 50-150mm | 10-30m*1200mm |

2 | Inorganic fibers spraying glass wool manufactory | 12 | 50-150mm | 10-30m*1200mm |

3 | Inorganic fibers spraying glass wool manufactory | 14 | 40-150mm | 10-30m*1200mm |

4 | Inorganic fibers spraying glass wool wool manufactory | 16 | 25-150mm | 10-30m*1200mm |

5 | Inorganic fibers spraying glass wool manufactory | 18 | 25-150mm | 10-30m*1200mm |

6 | Inorganic fibers spraying glass wool manufactory | 20 | 25-150mm | 10-30m*1200mm |

7 | Inorganic fibers spraying glass wool manufactory | 22 | 25-150mm | 10-30m*1200mm |

8 | Inorganic fibers spraying glass wool manufactory | 24 | 25-150mm | 10-20m*1200mm |

9 | Inorganic fibers spraying glass wool manufactory | 32 | 25-150mm | 10-20m*1200mm |

10 | Inorganic fibers spraying glass wool manufactory | 38 | 15-150mm | 10-20m*1200mm |

11 | Inorganic fibers spraying glass wool manufactory | 48 | 10-120mm | 10-20m*1200mm |

We can also produce as request.

No. | Item | Unit | National Standard | Company Product | Remark |

1 | Density | kg/m3 | 10-48 | GB483.3-85 | |

2 | Average Fiber diameter | μm | ≤8.0 | 5.5 | GB5480.4-85 |

3 | Hygroscopicity | % | ≥98 | 98.2 | GB10299-88 |

4 | Thermal conductivity | W/M.K | ≤0.042 | 0.033 | GB10294-88 |

5 | Noncombustibility | 0 | Noncombustible | Noncombustible (A) | GB5464-85 |

6 | Sound Absorption Coefficient | 0 | 0 | 1.03 product reverberation method 24kg/m3 2000HZ | GBJ47-83 |

7 | Highest usage Temperature | °C | ≤480 | 480 | GB11835-89 |

• Heat preservation for steel structure building.

• Heat insulation for wall and roof of house to save energy.

• For indoor partition wall. Train compartment.

• For cool-making and high buildings required to be fireproof, heat resistant and sound insulating.

Packaging & Delivery

| Packaging Detail: | Thermal insualtion rock wool boards is packed in polythene plastic thermal-shrink film or plastic bag. |

| Delivery Detail: | Within 20 work days after we get the advanced 30 |

FACTORY:

- Q:What are the sound-absorbing fiber boards?

- The theory on the absorption coefficient is the best sound-absorbing board sound-absorbing effect 1 (all suck, no reflections), but in reality, this material does not exist (black holes in the universe are the sound absorption coefficient is 1, which is completely absorbed)

- Q:What are the standards for ceramic fiber boards?

- Ceramic fiber board is made of continuous production, water production line and advanced technology, ceramic fiber board produced with smooth surface, accurate size, good toughness, can be arbitrarily cut, good insulation effect and other performance characteristics.

- Q:Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Volume density is low: the density of the ceramic fiber lining is about 25% of the lining of the light heat insulation brick, about 10% of the lining of the light pouring material; adopting the fiber lining can greatly reduce the steel structure load of the furnace and prolong the service life of the furnace lining.

- Q:What are the differences between nano ceramic plate and ceramic fiber board?

- The biggest difference between the two is that:1, the coefficient of thermal conductivity is different, the nano ceramic plate is about three times of the ordinary ceramic fiber board2, temperature class is not the same, nano ceramic board maximum temperature of 1050 degrees, ceramic fiber board should be 1400 degrees temperature.3, the range of applications is different. Nano ceramic plate is mainly used in high, fine and sharp technical fields, and has strict requirements on thermal conductivity. Ceramic fiber boards are widely used and can be used wherever there is flame or temperature.

- Q:What is the difference between ceramic fiber board and nano ceramic fiber board?

- The nano ceramic fiber board through the introduction of nanotechnology, the special production process, product performance has been greatly improved, high strength, low thermal conductivity, good heat insulation performance, energy saving effect is obvious, which improves the safety of the furnace, and in high temperature and high pressure conditions, can also play a good performance the product.

- Q:Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Sheng Yang series of ceramic fiber board is based on the traditional process of comprehensive upgrading of the excellent vacuum forming insulation materials, slag ball content of less than 3%, fiber distribution uniformity, internal and external strength consistent, size controllable.Ceramic fiber board is made by spraying superfine ceramic fiber through water washing, slag removal, fiber freezing and vacuum forming. The product has superior high temperature resistance, excellent rigidity and toughness.

- Q:Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- 1, high compressive strength, long service life; 2, low heat capacity, low thermal conductivity;3, non brittle material, good toughness;4, accurate size, good flatness;5 、 easy to cut and install, easy to construct;6, excellent wind erosion resistance;7 、 continuous production, uniform distribution of fiber, stable performance.

- Q:What method should be used to measure the thermal conductivity of fiberboard?

- It is concluded that the test error of this method and device is about 2%. This filament ultra light aluminum silicate fiber product: the filament ultra light aluminum silicate product is by Shandong Zibo high quality burnt precious stone as raw material, passes through the smelting furnace, the rejection silk, blows the cotton, the auxiliary mold and so on to deliver the work procedure. Therefore, the thermal conductivity of fiberboard is chosen by heat flow meter method.

- Q:How much pressure can the ceramic fiber board withstand?

- Ceramic fiber board divided by density, can be divided into ceramic fiber, ceramic fiber board density 250-260Kg/m fand; density, fand 300-350Kg/m;

- Q:What are the uses of ceramic fiber boards?

- Ceramic fiber board is the main use of heat insulation, fire protection, insulation to use, but also with sound absorption, noise reduction, thermal shock resistance and so on. Ceramic fiber board is mainly used in all kinds of furnace lining insulation, kiln wall lining insulation, metallurgical industry furnace fire, aluminum reduction tank, refractory brick backing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heat Resistant Rock Wool Board CMAX

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords