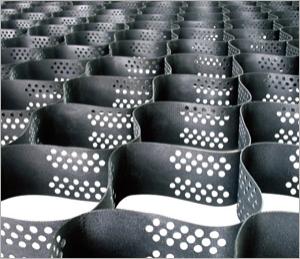

HDPE Smooth Geocell Grass Paver with Vigrin Material and Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Best Price HDPE Smooth Geocell Grass Paver

Polymer Density | High Density Polyethylene with density of 0.935 - 0.965 g/cm3 ASTM D 1505 |

Environmental Stress Crack Resistance | > 4000 hours ASTM D 1693 |

Carbon Black Content | Carbon black content 1.5% - 2.0% ASTM D 1603 |

Sheet Thickness | Smooth:1.1mm,1.2mm,textured:1.5mm ,1.7mm ASTM D 5199 |

Cell Details | welding distance:330-1000mm |

Cell Depth | 50-250mm |

Seam Peel Strength | As per US Army Corps of Engineer's Report GL-86-19 Appendix A |

Seam Hang Strength | A 100mm wide seam sample supports a 72.5 kg load for a minimum of 30 days in an ambient room temperature environment. |

Certification | CE ,ISO |

Classification | 1. smooth surface without hole 2. smooth surface with hole 3. textured surface with hole 4. textured surface without hole |

Applying Area of Best Price HDPE Smooth Geocell Grass Paver

1.Be used for firm the roadbed of railroad;2.Be used for firm highway soft foundation handling;

3.Be used for dike and retaining wall, which can bear load force;

4.Be used to harness the shoal water runway;

5.As pipeline and the sewer's propping up structure;

6.Be used for mixed type retaining wall that prevent the slope from falling down and bear load force;

7.Be used for independent wall, dock and breakwater;

8.Be used to harness the desert, beach and riverbed ,river bank

HDPE Geocell Technical Data Best Price HDPE Smooth Geocell Grass Paver

Height (mm) | Welding distance (mm) | Sheet thickness(mm) | Tensile yield strength of the cell≥(MPa) | Seam peel strength≥(N) | ||

smooth | textured | |||||

GS50-400 | 50 | 400 | 1-1.1 | 1.4-1.5 | 20 | 500 |

GS100-400 | 100 | 400 | 1-1.1 | 1.4-1.5 | 20 | 1000 |

GS150-400 | 150 | 400 | 1-1.1 | 1.4-1.5 | 20 | 1500 |

GS200-400 | 200 | 400 | 1-1.1 | 1.4-1.5 | 20 | 2000 |

GS75-330 | 75 | 400 | 1-1.1 | 1.4-1.5 | 20 | 750 |

GS100-330 | 100 | 400 | 1-1.1 | 1.4-1.5 | 20 | 1000 |

GS150-330 | 150 | 400 | 1-1.1 | 1.4-1.5 | 20 | 1500 |

GS200-330 | 200 | 400 | 1-1.1 | 1.4-1.5 | 20 | 2000 |

High Strength HDPE Geocell Technical Data

NO. | Test Item | Unit | Index |

1 | Band tensile strength | MPa | ≥200 |

2 | Tensile strength at connecting | N/cm | ≥150 |

3 | Break elongation | % | ≤15 |

- Q:How do geocells reduce construction costs?

- Geocells reduce construction costs by providing a cost-effective and efficient solution for soil stabilization, erosion control, and pavement construction. These three-dimensional honeycomb-like structures are made of high-density polyethylene (HDPE) and can be easily installed, filled with local material, and compacted, eliminating the need for expensive imported materials. Geocells also enhance load distribution, minimize soil settlement, and increase the lifespan of the pavement or structure, resulting in long-term cost savings.

- Q:Are geocells suitable for slope stabilization in landslide-prone areas?

- Yes, geocells are suitable for slope stabilization in landslide-prone areas. They provide excellent reinforcement and confinement to the soil, enhancing its strength and stability. Geocells also promote vegetation growth, which further improves slope stability and helps prevent erosion. Additionally, geocells are cost-effective and environmentally friendly, making them a viable solution for landslide prevention in such areas.

- Q:How do geocells improve soil stability?

- Geocells improve soil stability by confining and reinforcing the soil, preventing lateral movement and erosion. The interconnected cell structure of geocells creates a stable foundation by distributing and transferring loads more effectively, reducing soil displacement and settlement, and increasing overall strength and durability of the soil structure.

- Q:Can geocells be used for sand dune stabilization?

- Yes, geocells can be used for sand dune stabilization. Geocells are cellular confinement systems made of plastic or geotextile materials that can be filled with sand or soil. These cells provide structural support and help prevent erosion by stabilizing the sand particles and reducing wind and water movement. By creating a stable platform, geocells can help in stabilizing sand dunes and preventing them from shifting or migrating.

- Q:How do geocells improve load distribution?

- Geocells improve load distribution by confining and stabilizing the infill material, such as soil or aggregate, within the cell structure. This confinement prevents lateral spreading of the infill material under load, ensuring a more even distribution of weight and reducing the potential for differential settlement. Additionally, the interconnected cells create a three-dimensional honeycomb-like structure that enhances load-bearing capacity and provides additional strength to the overall system.

- Q:Are geocells resistant to fire?

- No, geocells are not resistant to fire.

- Q:Can geocells be used in retaining wall facing systems?

- Yes, geocells can be used in retaining wall facing systems. Geocells are three-dimensional cellular structures made from high-density polyethylene (HDPE) materials. They are commonly used in soil stabilization and erosion control applications. In retaining wall facing systems, geocells can be filled with soil or aggregate materials to create a stable facing structure that enhances the aesthetics and stability of the wall. The interlocking cells provide confinement and support, preventing soil erosion and reducing the potential for wall failure. Therefore, geocells are a viable option for retaining wall facing systems.

- Q:How do geocells improve the stability of roadways?

- Geocells improve the stability of roadways by confining and reinforcing the fill material, preventing lateral movement and increasing load-bearing capacity. The interconnected cells create a rigid structure that distributes the load evenly, reducing deformation and improving overall stability.

- Q:Can geocells be used for pipeline backfill?

- Yes, geocells can be used for pipeline backfill. Geocells are three-dimensional cellular confinement systems made from high-density polyethylene materials that can provide structural support and stability to soil and other materials. They are often used in civil engineering applications, including pipeline construction, to enhance the load-bearing capacity of the backfill material and prevent soil settlement. Geocells can effectively distribute loads and reduce lateral movement, making them an ideal solution for pipeline backfill to ensure long-term stability and minimize the risk of damage.

- Q:What are the benefits of using geocells in oil and gas industry applications?

- There are several benefits of using geocells in oil and gas industry applications. Firstly, geocells provide a stable and durable foundation for infrastructure such as access roads, well pads, and pipelines. This helps in reducing maintenance costs and prolonging the lifespan of the infrastructure. Secondly, geocells help in controlling soil erosion and preventing sedimentation, especially in areas with steep slopes or unstable soil conditions. This minimizes the risk of environmental damage and ensures compliance with regulations. Additionally, geocells improve the load-bearing capacity of the soil, allowing heavy equipment and vehicles to operate safely in challenging terrains. This enhances overall operational efficiency and reduces the likelihood of accidents or equipment damage. Moreover, geocells can be easily installed and are highly adaptable to different site conditions, making them a cost-effective solution for temporary or remote oil and gas operations. They can be quickly deployed and removed as needed, minimizing construction time and reducing environmental disturbance. Overall, the use of geocells in the oil and gas industry offers numerous advantages including improved infrastructure stability, environmental protection, enhanced safety, and cost savings.

1. Manufacturer Overview |

|

|---|---|

| Location | Taian City,Shandong Province,China |

| Year Established | 2003 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa, North America, Eastern Europe, South Asia, Western Europe |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao Port;Tianjing Port;Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Geotechnical Material (Geogrid,Fiberglass/Polyester Geogrid;Geocell;Geonet and Geomat;Plastic Safety Fence);Plastics products;Rubber products;Geotextile;Carpet;Compound geomembrane |

| Product Price Range | Average |

Send your message to us

HDPE Smooth Geocell Grass Paver with Vigrin Material and Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords