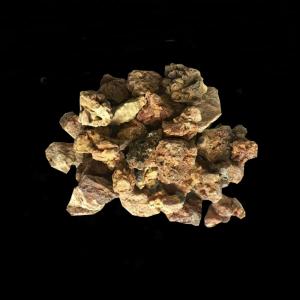

Fused Magnesite High Grade for Refractory Field

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Quick Details

Place of Origin: Liaoning, China

Application: Refractory

Shape: Block

Material: Magnesite

Chemical Composition: Mgo;CaO;SiO2

Mgo:96%-97%

Product name: FM

Payments terms: 1. 100% L/C at sight 2. 30% T/T prepayment, balance against BL copy

Delivery Time: Within 30 days after receiving L/C or 30% T/T prepayment

Usage: Metallurgy, Foundry, Abrasive, Refractory, Deoxidizer

Advantage: Timely Shipment, High quality, Good performance

Packing: 1mt/bag or as customers' requirements

Size: 0-30mm etc

Sample supply: free sample

Color: Brown, white

MOQ: 25Mt

Supply Ability

Supply Ability:1000 Metric Ton/Metric Tons per Month

Grade | MgO | SiO2 | CaO | Fe2O3 | Al2O3 | Loi | B.D g/cm3 |

Dicalcium-fused magnesium | 97.00 | 0.70 | 1.40 | 0.60 | 0.20 | 0.10 | 3.30-3.36 |

96.50 | 0.85 | 1.60 | 0.70 | 0.20 | 0.15 | 3.20-3.30 | |

96.00 | 0.95 | 1.90 | 0.80 | 0.23 | 0.12 | 3.20-3.30 | |

Common fused magnesite | 97.20 | 0.80 | 1.10 | 0.60 | 0.20 | 0.10 | 3.30-3.36 |

96.50 | 1.20 | 1.30 | 0.70 | 0.20 | 0.10 | 3.20-3.30 | |

96.00 | 1.40 | 1.50 | 0.80 | 0.20 | 0.10 | 3.20-3.30 | |

Size | 0-1mm, 0-30mm, 1-15mm, 1-30mm, 200mesh or according to customer's requirements. | ||||||

Plant photos:

Packaging & Delivery

Packaging Details1MT/bag or as customers' requirements.

Port Main port of China

Loading:

What is fused magnesite?

Fused magnesite is produced by high quality magnesite through electro- fusing, After melting, the SiO2 of material moves to the surface for the difference in the specific, so it has well grown crystals, well crystal perfection and structure homogeneity, excellent chemical stability, good corrosion resistance to slag and high strength at high temperature.

Where to apply fused magnesite?

It is widely used for gunning materials, fused magnesite ramming material, magnesite brick, magnesite chrome brick, vacuum and vacuum induction furnace, electric arc furnace refractory lining, magnesia crucible, furnace and a variety of refractory, such as large scale glass furnace by floating method, electrical furnace, convert furnace, house hold electrical appliances as electrical insulating materials,

- Q:What are the specifications of fireclay bricks?

- Standard sizes of refractory bricks in our country are: 230mm × 114mm × 65mm; standard density: 1, Diatomite insulating bricks 0.7 g / cubic centimeter; 2, Clay bricks 2.9 g / cubic centimeter; 3, High alumina brick 3.2 g / cubic centimeter. You can convert according to the actual volume, and the reference value can be calculated.

- Q:how is the high-temperature flame-retardant fibre board?

- The market is mainly divided into three kind of fiber. Density fiberboard, medium density fiberboard, high density fiberboard. Density fiberboard: It is rolled timber sheet made of wood shaving material produced by timber or non timber fiber that is added with or without glue or auxiliary material. A density of less than 450 kg / cubic meter, the larger fiber particles, the internal structure is not homogeneous, relatively lack of strength, lighter weight. MDF: use wood fiber or other plant fiber as material, added with glue. A sheet pressed at high temperature and pressure. A density between 450-880 kg / cubic meter, fiber particles is moderate, well proportioned internal structure, greater strength, moderate weight. HDF: Use wood fiber or other plant fiber as material, added with glue. A sheet pressed at high temperature and pressure. Its density is about 880 kg / cubic meter, small fiber particles, well proportioned internal structure, greater strength, greater weight. there are also artificial boards such as chipboard and melamine board in the market, generally used for making furnitures. the thickness of fiberboard that is produced and controlled more flexibly, is generally 5 per cent (general bulk price of 30 yuan per square meter), 9 cm (50 yuan), 18 cm (100), 25 cm (120), etc. There are thicker. However, proper deviation is acceptable. The board is usually thicker or thinner than the specified thickness. For example, It is only 16mm when specified 18mm.

- Q:what's the requirements of refractory for forge furnace?

- accurate answers please refer to Current Situation and Development Trend of Refractory Material in Heating Furnace ,Quality Requirement of Modern Industrial Furnace Refractory Material(GB/T17638-1998) Standard,Furnace-constructing Technology, if you need the mail box, please senf e-mail to me, my QQ number: 249704548.

- Q:How to classify the grade of wall fireproof and thermal inuslation matertial?

- The level classification of wall fireproof and thermal inuslation matertial: Grade A: incombustible building material: Material almost with no combustion. Grade B1: nonflammable building material: Nonflammable material has good flame resistance. It is difficult to fire in case of fire in the air or at high temperature. It is not easy to quickly spread. After the fire source is removed, combustion stops immediately. Grade B2: combustible?building?material: Combustible materials have a certain flame resistance. It will immediately burst into flames in case of fire in the air or at high temperature and is easy to lead to the spread of fire, such as wooden column, timber roof truss, timber beam, wooden stairs, etc. Grade B3: Flammable building material: It has no flame-retardant effect and is highly flammable. Fire hazard is very large.

- Q:Is fireclay corrosive?

- No. All of the refractory materials have stable chemical properties and their usability can be guaranteed under high temperatures.

- Q:Who knows about roof fireproofing materials?

- Roof water proofing materials: synthetic polymer waterproof rolls, high polymer modified asphalt waterproof coiled material, sheet metal, synthetic polymer waterproof coating, one-component water curing polyurethane waterproof coating, penetration crystalline waterproof coating. Secondly, we have to choose materials that are suitable for roof water proofing. The right waterproof materials have better waterproof performance, TS-3B one-component water curing polyurethane waterproof coating is very suitable and the performance is good. Since traditional roof waterproofing materials have requirements on the moisture content of the formation level which should be less than 9%. It is really important to choose which materials to repair leaking roofs. Kitchens and toilets are moisture, the formation levels of buildings are hard to satisfy requirements, thus, waterproof?layer and formation level are easily get separated and are ineffective in waterproofing.

- Q:What kind of material is refractory fiber?

- Refractory fiber, also known as ceramic fiber, is a fibrous thermal insulation refractory. Refractory fiber, also known as ceramic fiber, is a fibrous thermal insulation refractory. It has the characteristics of ordinary fibers, such as softness, flexibility, having a certain tensile strength. And it can be further processed into a variety of products such as paper, wire, rope, tape, blankets and felts. Besides, it has high temperature resistance and corrosion resistance which ordinary fibers don't have. As a fire retardant and thermal insulated material, it has been widely used in metallurgy, chemical, machinery, building materials, shipbuilding, aviation, aerospace and other industrial sectors.

- Q:What is the use of refractory?

- It is used as a protective layer inside the high-temperature, high-corrosion, high-washing, easy to be wore equipment and as an insulation layer outside equipment.

- Q:What are the common refractory insulation cotton material?

- Fire resistant thermal insulation material mainly refers to inorganic thermal insulation material and compround thermal insulation material. According to the shape can be divided into: Fibrous finishes, slag wool, rock wool, glass wool, aluminum silicate cotton. ceramic fiber, micro pile of diatomite, calcium silicate, expanded perlite, expanded vermiculite, aerated concrete etc., foam like bubble glass, volcanic ash glass, foam clay, foaming concrete, paste powder polystyrene particles insulation slurry Their common characteristics is fire resistant, applicable for buildings that have high requirement for fire resisitance level. Calcium silicate, aluminum silicate, asbestos, etc. can also be used for thermal insulation of high temperature heat transfer pipe. I hope my answer can help you

- Q:What are the materials for refractory materials? What are their names?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, there are refractories for special occasions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fused Magnesite High Grade for Refractory Field

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords