Fiberglass Geogrid With CE ISO certification

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid With CE ISO certification

Intriduction of Fiberglass Geogrid:

CMAX fiberglass georid is based on fiberglass woven cloth with modified bitumen or PVC, it was developed to address the problem of pavement cracing on highways, roads and runways, driven by a need to reduce cost for infrastructure maintanance and repair.

It is a characterized by high tensile strength in axial and lateral direcions,low stretch rate, alkali-resistance, low temperature-resistance, as well as convenience in construction and low price. It can be on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs,harbors,ports,water channels,seawalls,etc.

Advantages of Fiberglass Geogrid:

High strength, high modulus and low temperatures resistance.

Applications of Fiberglass Geogrid:

1. It reinforces old asphalt concrete road surface and asphalt surface layer, and prevents damage;

2. it used for rebuilding cement concrete road surface into composite road surface and restraining reflection caused by block contraction;

3. it is used in road expansion and improvement project and crack caused by old and new combination position and uneven sedimentation;

4. it is used in soft soil base reinforcement treatment ,is favorable for soft soil water separation and concretion, restrains sedimentation effectively, distributes stress uniformly and improve overall strength of road base;

5. it is used for preventing contraction crack caused by new road semi-rigid base layer, and reinforcing and preventing road surface crack caused by foundation crack reflection

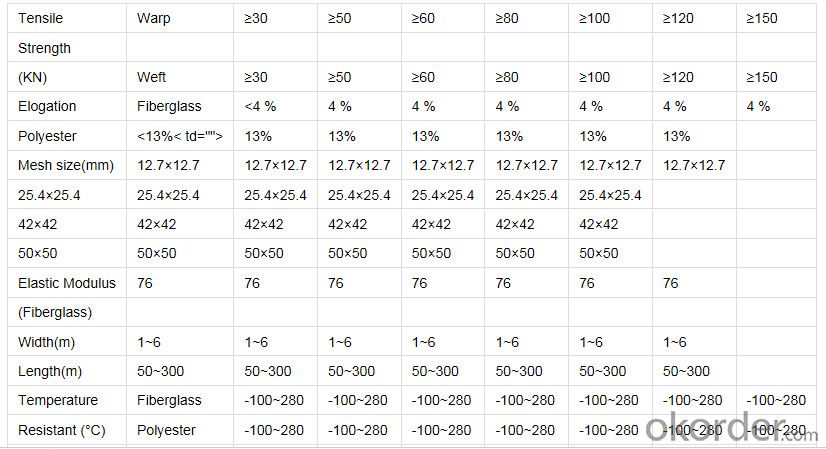

Specifications of Fiberglass Geogrid:

FAQ:

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Our products are with much higher standard than Chinese standard, and it can reach CE certification. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

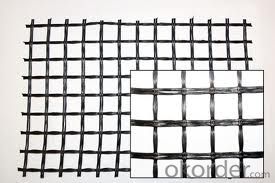

Photos of Fiberglass Geogrid:

- Q:What are the different types of geogrids?

- There are several types of geogrids, including uniaxial geogrids, biaxial geogrids, and triaxial geogrids. Uniaxial geogrids have strength in only one direction and are often used for soil reinforcement in walls and embankments. Biaxial geogrids offer strength in two perpendicular directions and are commonly used for stabilizing and reinforcing soil in applications such as road construction and retaining walls. Triaxial geogrids provide strength in all three directions, making them suitable for stabilization and reinforcement in areas with complex soil conditions or heavy loads.

- Q:Geogrid width mean?

- Because the geogrid is packed, generally (1--6) * (50 or 100 m)

- Q:What is the typical geogrid roll length for specific applications?

- The typical geogrid roll length for specific applications can vary depending on the project requirements and the specific type of geogrid being used. However, common geogrid roll lengths range from 50 to 500 feet, with some specialty products available in longer lengths.

- Q:Can geogrids be used in stabilization of coastal dunes?

- Yes, geogrids can be used in the stabilization of coastal dunes. Geogrids are effective in providing reinforcement and preventing erosion in sandy and loose soil conditions. By installing geogrids, the dunes can be strengthened, reducing the risk of erosion and maintaining the stability of the coastal area.

- Q:Can geogrids be used for reinforcement in asphalt overlays?

- Yes, geogrids can be used for reinforcement in asphalt overlays. They are commonly used to improve the structural integrity and durability of asphalt overlays by providing additional support and reducing the potential for cracking and rutting. Geogrids can help distribute the load more evenly, increase the tensile strength of the pavement, and enhance long-term performance.

- Q:How do geogrids improve the performance of flexible bridge abutments?

- Geogrids improve the performance of flexible bridge abutments by providing reinforcement and stabilization to the soil. These synthetic materials are placed within the backfill soil behind the abutment, increasing its strength and load-bearing capacity. Geogrids also help distribute the load more evenly, reducing stress and potential settlement. This reinforcement prevents excessive movement and settlement of the abutment, ensuring its stability and longevity.

- Q:How do geogrids improve the load transfer in road pavements?

- Geogrids improve the load transfer in road pavements by providing reinforcement and stabilization to the layers of the pavement. They are typically made of high-strength materials and are placed within the pavement layers to distribute the load more evenly, reduce deformation, and enhance the overall structural integrity of the road. This helps in preventing cracks, rutting, and other pavement distresses, ultimately extending the lifespan and improving the performance of the road.

- Q:Can geogrids be used in reinforcement of underground storage facilities for hazardous materials?

- Yes, geogrids can be used in the reinforcement of underground storage facilities for hazardous materials. Geogrids are highly effective in providing soil reinforcement and stabilization, which is crucial for ensuring the structural integrity and safety of underground storage facilities. By enhancing the load-bearing capacity of the surrounding soil, geogrids can help prevent ground movements and potential leaks or ruptures, thereby minimizing the risks associated with storing hazardous materials.

- Q:Can geogrids be used in soil reinforcement for load-bearing platforms?

- Yes, geogrids can be effectively used in soil reinforcement for load-bearing platforms. Geogrids are engineered materials that provide soil stabilization and improve the load-bearing capacity of soils. They are typically made of high-strength polymers and have a grid-like structure that interlocks with the soil particles, creating a stable foundation. Geogrids distribute the applied loads more evenly, reducing the potential for soil settlement and enhancing the overall stability of load-bearing platforms.

- Q:What are the benefits of using geogrids in construction?

- Geogrids offer several benefits in construction, including improved stability and reinforcement of soil, increased load-bearing capacity, reduced soil erosion, enhanced drainage, and cost-effectiveness. They act as a strong reinforcement material, distributing loads evenly and preventing soil movement. Geogrids also provide long-term durability, resistance to harsh environmental conditions, and versatility in various construction projects. Overall, the use of geogrids can significantly enhance the performance and longevity of structures while minimizing maintenance requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrid With CE ISO certification

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords