cold rolled stainless steel welded pipe

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel pipe

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube

Specifications

1.Specification:21.3*3.73mm or others

2.Surface:4k/6k//8k

3.Length:6m or as your requirement

A series of photos

A series of pictures

- Q:Are stainless steel pipes suitable for compressed air systems?

- Yes, stainless steel pipes are suitable for compressed air systems. Stainless steel has excellent corrosion resistance, high strength, and can withstand high-pressure conditions, making it a reliable choice for transporting compressed air. Additionally, stainless steel pipes are durable and have a long lifespan, minimizing the need for frequent replacements.

- Q:Are stainless steel pipes suitable for pulp and paper mills?

- Absolutely, pulp and paper mills can definitely rely on stainless steel pipes. Stainless steel pipes possess a plethora of advantages that render them perfect for utilization in this particular sector. Firstly, stainless steel is remarkably resistant to corrosion and can endure the harsh chemicals and high temperatures commonly encountered in pulp and paper mills. This corrosion resistance guarantees that these pipes will have a lengthier lifespan, necessitating less maintenance and reducing downtime and costs linked with repairs or replacements. Furthermore, stainless steel pipes are acknowledged for their robustness and durability. They can handle high-pressure circumstances, ensuring a dependable and efficient flow of materials throughout the mill. This is especially crucial in pulp and paper mills where substantial volumes of water, chemicals, and pulp need to be transported. Additionally, stainless steel pipes are hygienic and effortless to clean, rendering them well-suited for applications in the pulp and paper industry that demand meticulous cleanliness standards. The smooth surface of stainless steel pipes also diminishes the likelihood of contamination and guarantees a seamless flow of materials, averting any blockages or clogs that could impede production. To conclude, due to their corrosion resistance, durability, strength, and ease of cleaning, stainless steel pipes are undeniably appropriate for pulp and paper mills. They provide a reliable and efficient solution for transporting materials, thereby facilitating the smooth operation of the mill and minimizing maintenance requirements.

- Q:Can stainless steel pipes be used for air pollution control systems?

- Yes, stainless steel pipes can be used for air pollution control systems. Stainless steel is known for its corrosion resistance, durability, and high-temperature strength, making it a suitable material for handling corrosive gases and pollutants in air pollution control systems. Additionally, stainless steel pipes offer excellent resistance to chemical reactions and can withstand harsh operating conditions, making them an ideal choice for such applications.

- Q:Can stainless steel pipes be insulated with fiberglass?

- Fiberglass insulation is a viable option for insulating stainless steel pipes. Its exceptional thermal resistance characteristics make it a popular choice for pipe insulation. By preventing heat loss or gain, it enhances energy efficiency. Moreover, fiberglass insulation is lightweight, simple to install, and can be easily customized to fit pipes of different sizes and shapes. It also offers excellent sound insulation properties and is non-combustible. Thus, fiberglass insulation is the ideal solution for insulating stainless steel pipes.

- Q:How do you prevent corrosion in stainless steel pipes?

- To prevent corrosion in stainless steel pipes, there are a few measures that can be taken. Firstly, it is important to ensure that the stainless steel pipes are made from a high-quality grade of stainless steel. Different grades of stainless steel have varying levels of resistance to corrosion, so selecting the appropriate grade for the specific application is crucial. Secondly, regular cleaning and maintenance of the stainless steel pipes is essential. This involves removing any dirt, debris, or contaminants that can potentially cause corrosion. Cleaning can be done using mild soap or detergent, followed by rinsing with clean water and drying the pipes thoroughly. Moreover, it is advisable to avoid using abrasive cleaners or scrubbers that can scratch the surface of the stainless steel pipes, as this can create small crevices where corrosion can occur. Instead, soft cloth or sponge should be used for cleaning. Additionally, it is essential to protect stainless steel pipes from exposure to corrosive substances or environments. This can be achieved by applying a protective coating or using a corrosion-resistant paint on the pipes. This barrier will prevent direct contact between the stainless steel and corrosive substances, reducing the risk of corrosion. Furthermore, maintaining proper water chemistry is important for preventing corrosion in stainless steel pipes used for plumbing applications. Monitoring and controlling the pH level, hardness, and alkalinity of the water can help minimize the corrosive effects on the pipes. Lastly, ensuring proper installation and design of stainless steel pipes is crucial. This includes avoiding tight bends or sharp corners, which can trap moisture and lead to corrosion. Proper insulation and ventilation should also be considered to prevent condensation and subsequent corrosion. By following these preventive measures, corrosion in stainless steel pipes can be significantly reduced, ensuring their longevity and optimal performance.

- Q:Are stainless steel pipes suitable for marine applications?

- Yes, stainless steel pipes are suitable for marine applications. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions of saltwater, making it a popular choice for marine applications such as shipbuilding, offshore structures, and marine equipment. It provides excellent durability, strength, and long-term performance in marine environments.

- Q:Are stainless steel pipes suitable for brewery fermentation tanks?

- Yes, stainless steel pipes are suitable for brewery fermentation tanks. Stainless steel has several properties that make it ideal for use in the brewing industry. Firstly, stainless steel is resistant to corrosion, which is crucial in a brewery environment where the tanks are exposed to liquids such as beer and cleaning chemicals. This resistance to corrosion ensures that the pipes will not rust or contaminate the beer during the fermentation process. Additionally, stainless steel is a hygienic material that can be easily cleaned and sanitized, making it perfect for use in the brewing industry where cleanliness is of utmost importance. The smooth surface of stainless steel pipes also prevents the growth of bacteria and other microorganisms, further ensuring the quality and safety of the beer. Furthermore, stainless steel pipes have excellent heat resistance, allowing them to withstand high temperatures during the brewing process without warping or deforming. This durability and heat resistance make stainless steel pipes suitable for use in the fermentation tanks, where the beer is subjected to specific temperature conditions. Overall, stainless steel pipes provide the necessary durability, corrosion resistance, cleanliness, and heat resistance required for brewery fermentation tanks. They are a reliable and suitable choice for maintaining the quality and integrity of the beer during the fermentation process.

- Q:What is the thermal conductivity of stainless steel pipes?

- The thermal conductivity of stainless steel pipes varies depending on the specific grade of stainless steel being used. However, on average, stainless steel pipes have a thermal conductivity ranging from 15 to 24 W/m·K (watts per meter kelvin).

- Q:What are the different types of stainless steel pipe insulation?

- There are several types of stainless steel pipe insulation available, including fiberglass, mineral wool, foam, and elastomeric foam. These materials provide different levels of thermal performance, durability, and resistance to moisture and chemicals, allowing users to choose the most suitable option for their specific needs.

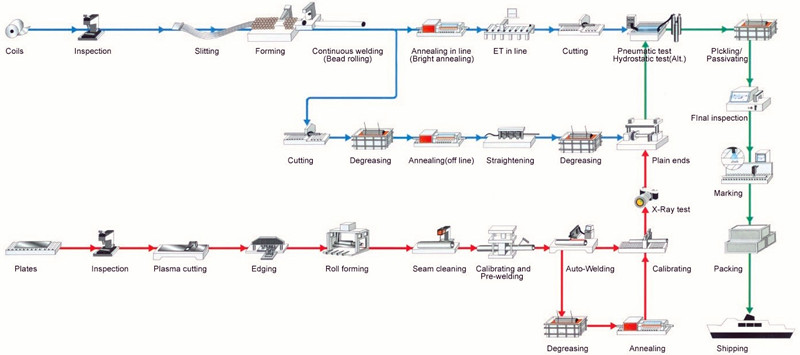

- Q:What is the difference between seamless and seamless annealed stainless steel pipes?

- The main difference between seamless and seamless annealed stainless steel pipes lies in their manufacturing process and the resulting properties of the pipes. Seamless stainless steel pipes are manufactured by piercing a hot billet or a solid bar to form a hollow cylindrical shape. This process eliminates the need for welding or any other joints, resulting in a uniform and continuous pipe with no seams. Seamless pipes are known for their excellent strength and ability to withstand high pressures, making them suitable for various applications in industries such as oil and gas, petrochemical, and construction. On the other hand, seamless annealed stainless steel pipes go through an additional heat treatment process called annealing. Annealing involves heating the pipe to a specific temperature, holding it at that temperature for a certain duration, and then cooling it slowly. This heat treatment helps to relieve internal stresses, reduce hardness, improve ductility, and enhance the overall mechanical properties of the stainless steel pipe. The annealing process also leads to the formation of a more homogenous microstructure, which further improves the corrosion resistance of the stainless steel. This makes seamless annealed stainless steel pipes particularly suitable for applications where excellent corrosion resistance is required, such as in the chemical processing, pharmaceutical, and food and beverage industries. In summary, while both seamless and seamless annealed stainless steel pipes are produced without any seams, the additional annealing process in the latter enhances its mechanical properties and corrosion resistance, making it more suitable for certain industries and applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

cold rolled stainless steel welded pipe

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords