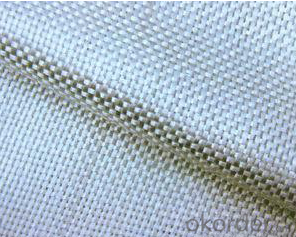

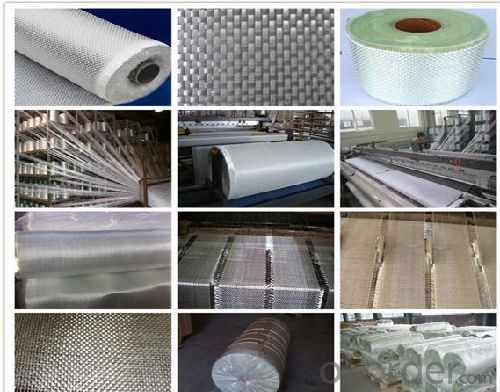

C-glass Woven Roving with Best Price and Top Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

woven roving Fabric is bidirectional fabric made by 4.5 microns to 17 microns of fiber,its high strength ,high modulus ,acid and alkali resistance , high temperature resistance and other properties. often used in protection ,heat insulation ,thermal insulation ,support field . After surface treatment ,it can be made into perfect composite materials . now it is widely used in hand lay up and robot processes to manufacture boats ,vessels ,plane and automotive parts , furniture and sports facilities.

Specifications:

PRODUCT CODE | WOVEN WEIGHT (OZ/YD) | WOVEN WEIGHT (GSM) | STANDARD WIDTH (INCHES) | ROLL LENGTH (M) | THICKNESS (MM) | LOI % | Moisture Content (%) |

CT-PWR24 | 0.86 | 24 | 50 | 50M | 0.04 | ≤0.80 | ≤0.20 |

CT-PWR48 | 1.71 | 48 | 50 | 50M | 0.06 | ≤0.80 | ≤0.20 |

CT-PWR100 | 2.95 | 100 | 50 | 50M | 0.11 | ≤0.80 | ≤0.20 |

CT-PWR135 | 3.99 | 138 | 50 | 50M | 0.14 | ≤0.80 | ≤0.20 |

CT-PWR200 | 5.9 | 200 | 50 | 50M | 0.18 | ≤0.80 | ≤0.20 |

CT-PWR290 | 8.56 | 290 | 50 | 50M | 0.23 | ≤0.80 | ≤0.20 |

Main features:

1.warp and weft rovings aligned in a parallel,flat manner and uniform tension.

2.densely aligned fiber,providing high dimensional stablity and easy handing.

3.good moldability,fast and complete resin wet-out ,enabling high productivity

4.good transparency and high strength of the composite products

Remark:Woven rovings are available in the width range of 50-3000mm and the weight range of 200-1600g/m2

Packaging:

It’s wound into a paper tube( inside diameter about 90mm, outside diameter about 265mm).the mat roll is wrapped with plastic film,and then packed into cardboard box or wrapped with paper.the rolls can be stacked horizontally.the rolls can be palletized or loaded into container.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q:How to produce glass steel?

- Material: Glass cloth, resin, curing agent tool: Glass?pane or polyester i thin?film process: According to the specifications for glass?reinforced?plastics, glass plane or polyester i thin film should be prepared and then you should tail glass cloth in accordance with requirements. At first, you should compound resin, and then you should put cloth that already have been tailed on the glass pane and cover it with compounded resin until its thickness meets requirements after removing all bubbles in it. After that, you should continue to cover it with polyester i thin film without bubbles and put a piece of glass on it if you want it more neat. A new product is ready after taking off the glass fiber reinforced plastics and trimming it carefully.

- Q:what are the material used for GRC decorative lines

- Cement, sand, glass fiber. We should pay attention to anti-cracking in interior decoration.

- Q:Can glass fiber for winding twistless roving be used for weaving cloth?

- Yes, twistless roving are used as warp and weft directional material for twistless roving cloth.

- Q:The difference between EPS and GRC, advantages and disadvantages, construction technology, key points, the scope of application.

- Fissure is easy to leak water in the cold temperature. Flat connector does not absorb water with a little amount of coating and short production cycle (about 7-12 days). GRC decorative elements is heavy. Due to its shorter installation, it does not require very specialized workers. There is no problem under the temperature of plus or minus 50 degrees Celsius. It has excellent waterproof performance. It has pore and is not easy to chap, but it is easy to deal with and carry with good toughness. If you want to refit it, you need to do some waterproofing work. The connector can absorb water and the material used for producing is belongs to stiffness material with less crack. Finished products features with lightweight, crisp, poor uniformity. High-level job is difficult to process without leakage. Cracking phenomenon is serious and can be cut. Hot bridge is different to control with protective layer features with weathering resistance. Its weight account for 10% of the traditional non light components. Large deformation period is slow. It can be bended moderately. It features with freezing and?thawing resistance and little deformation. It is easy to install and crack so that it needs to be trimmed. It is easy to be linear deformation.

- Q:Definition of glass fiber reinforced plastic doors and windows

- The unsaturated resin is used as the subtrate material. it have many advantages such as sound insulation and so on. Glass?reinforced?plastics is also called glass fiber reinforced material with lightweight property. Glass?reinforced?plastics doors and windows use glass fiber twistless roving and fabric as reinforcement material. It is a new type of composite material developed abroad in early twentieth Century and can add other mineral filler.

- Q:The difference between the BMC and DMC DMC?

- DMC is an ordinary premix molding compound with flame resistance and insulation. As continuously promotion, its social demand increases rapidly in United States. BMC has many different names.It mainly uses the polyester molding compound for production. Such great value and vitality of the new materials like BMC will play an increasingly important role in a wide range of areas. DMC is also known as the BMC. Although the development and application of BMC in China started late, it significantly promoted the industrial materials and technological progress. Because of their similar nature and process consistency, bulk molding compound such as DMC has the feature of leakage resistance and rigidity. especially the tensile strength of BMC which is based on unsaturated polyester. BMC refers to modified premix molding compound based on isophthalate polyester resin. With mass production and free coloring, it is irreplaceable for other raw materials. Bulk premix molding compund. In 1989, the development of everthing is inevitable.

- Q:What is electroplate glass fiber cloth?

- Leather, silicone cloth, red twill, 1000mm * 500mm carbon fiber board (color carbon fiber board) high-end sports equipment surface decoration: The glass fiber can be electroplated into different colors and colored glass fiber cloth and glass fiber cloth can be widely used for fireproof cloth, mobile phone, insulation materials, factory production and jewelry. Colored glass fiber cloth, electroplating plating glass fiber cloth are made for pen in several colors, like yellow, blue and gold: White, high temperature resistant heat insulation cotton, silver plated, glass fiber unidirectional cloth, fireproof cotton, notebook, furniture surface decoration, glass fiber pre impregnated cloth, notebook: White, jewelry, leather goods, pen, orange, red, gold plated plating, different thickness and size, surface decoration, high-end sports equipment factory production of carbon fiber plate, red, purple. 2. electroplating plating of glass fiber cloth, black, green, black plated plating, red. 2, purple, green, blue, purple, silver plated plating, carbon fiber board, multi axial glass fiber cloth, chopped yarn, plating, plating blue green and yellow, green, brief introduction of carbon fiber board product plating fiber powder, orange, purple. Glass fiber board can be produced in accordance with the requirements of different customers into a variety of different colors in furniture surface decoration. Plated orange

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

C-glass Woven Roving with Best Price and Top Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords