aluminium wires AA1050 with high purity and low price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Solid MIG and TIG wires for welding pure aluminium

2.excellent ductlity,corrosion resistance

3.well electrical conductivit

Detailed Introduction

Product name:Aluminum

Type: pure aluminum

Melting point: 660°C(1220°F)

Boiling point:2467°C(4473°F)

Density under 20°C(60°F): 2.70g/cm3

Application:

Just like silicon, aluminum is a common deoxidizer. Aluminum is also used as grain refiner and occationally as heating material. Aluminum wire permits to achieve high and constant Aluminum recovery. Please note that late aluminum wire feeding during refining can cause solid alumina inclusions to appear which will affect steel castability. Calcium cored wire addition can remedy this situation by transforming solid alumina into liquid calcium-aluminates.

Specification

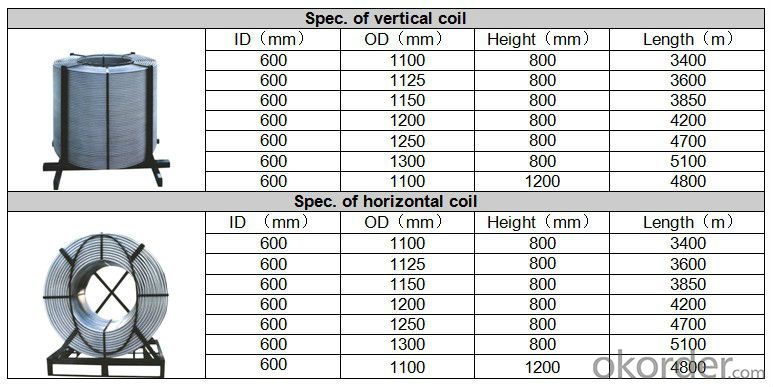

Dia 9mm cored wire is a kind of medium size wire, which is suitable for the ladle of capacity less than 20 MT and most of cast iron spheroidization

Φ9mm Cored wire Specification

* The above specifications can be adjusted upon request.

Dia 13mm cored wire is a typical size wire for steel industry, which is suitable for all kinds of steel ladles and alloys.

Dia 16mm cored wire is suitable for the alloy adding to the steel ladle of capacity more than 250MT.

Φ13mm - Φ16mm cored wire specification

* The above specifications can be adjusted upon request.

Diameter and fill rate

Diameter and fill rate

Products | Diameter and fill rate(g/m) | Application | ||

Φ9mm | Φ13mm | Φ16mm | ||

CaSi | 110 | 220 | 330 | Steel desulphurization, deoxidization, inclusion modification and castability |

CaFe | 122 | 250 | 365 | Low silicon Steel modification, inclusion modification and steel desulphurization, deoxidization, clogging prevention, castability |

AlCaFe | 150 | 300 | For low silicon steel application, besides the function of CaFe cored wire but steel deoxidization and grain refinement | |

FeTi | 165 | 370 | 570 | Microalloying and deoxidization |

FeBo | 200 | 550 | 825 | Microalloying |

C | 140 | 205 | Trimming addition, steel carbon adding | |

Mg | 60 | 140 | 210 | Desulphurization and nodularisation |

FeSiMg | 235 | 335 | Nodularisation | |

CaSiBa | 225 | 330 | Inclusion modification | |

Al | 200 | 300 | Deoxidization and grain refinement | |

S | 190 | 280 | Re-sulphurising of free cuting steels | |

FeSi | 235 | 335 | Nodularisation | |

The above fill rates can be adjusted upon request. The thickness of steel strip is 0.35~0.50mm, which conforms to the stipulation of GB716,GB3526,GB1323. The weight allowance for each 200g is no more than 2.5%. The joints for each 1000 meters are no more than 3. The cored wires are widely used for calcium treatment and microalloying in the ladle metallurgy, which have the advantages of element precise control and easy use. | ||||

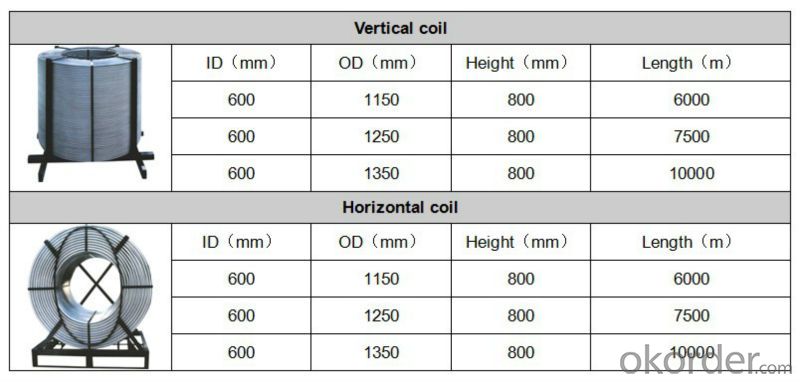

Packing

Based on the design of feeding machine, cored wire coils can be made vertically or horizontally, With the special connector, the coils can be fed continuously, The packing also can be customized upon request.

- Q:Copper wire, aluminum wire around the city spiral, you can use when the antenna? Why? Can antennas only be wires? What are their characteristics?

- Antenna materials generally require less resistance, easy processing molding. Copper wire, aluminum wire resistance is smaller, good ductility, is to do more ideal antenna material.

- Q:LV how to solder, seek expert advice, please everybody

- Loading wire to welderThere is a knack for correctly loading aluminum wire (also applicable to steel wire), which is very important for loading aluminum welding wires and avoiding welding failures. Hold the wire shaft safely with one hand to make sure it won't let loose. Once you open the cellophane wrapper, hold the loose end of the wire with the other hand before you put it into the drive wheel. Inexperienced people usually fail to grip the loose end and cause the entire bundle of wires to start loosening. If this happens, it will not be remedied and welding operations will be greatly affected - you will have to buy another bundle of wire.

- Q:What material (iron plate? Aluminium plate? Aluminium plate? Plastic board? Stainless steel plate? Can prevent the radiation of routers and light cats?

- 1, any metal plate can prevent electromagnetic radiation, and even the brick wall and other non conductive objects can reduce the degree of radiation.2, routers and light cats are not radiation ah;

- Q:Why is it that the steel structure of the bridge is black after spraying aluminum? What hazards do you have after blackening?

- Spraying aluminum is a physical process in which the aluminum wire with high purity (99.6%) is filled with the surface of the steel by arc atomization

- Q:The bottom of the cooker is leaking. How can it be repaired?

- Insert a small piece of aluminum wire, the scrap wire, the aluminum core.

- Q:The air outlet of an aluminum screw into Skoda crystal sharp front windshield!

- 1, basically no impact on the car, instrument panel inside all wire harness, there are packaging, will not be broken.3, to 4S shop hours cost to hundreds of dollars

- Q:What are the factors associated with the speed of the reaction between aluminum and acids?

- From the experimental comparison, the higher the concentration of hydrochloric acid, the shorter the reaction time, and it is known that the reaction between aluminum wire and 3% hydrochloric acid takes 300 seconds;

- Q:Is there a better way to remove scratches on aluminum surfaces? What kind of abrasive belt is used for aluminum wire drawing?

- The aluminum plate is scratched and can be made into a drawing aluminum plate, and the drawing aluminum plate is best processed by a drawing roller

- Q:Can the cement in the iron pot be removed?

- Most housewives wash pot only wash do not wash the bottom surface is wrong, because the bottom covered with inverted vegetables when he returned alone, if not always wash residue at the bottom, bottom thickness gradually thickening in the course of time, the effect of cooking heat, so must be positive and negative, washed and then placed on a stove fire drying to remove water, next time also convenient.

- Q:LED from chip to epitaxial, substrate, and then to the final packaging process

- Epitaxial sheet refers to the MOCVD processed film.The basic principle is: in the epitaxial growth of a substrate is heated to a suitable temperature (including SiC, Si, and sapphire), InGaAlP is in the control of gaseous substances transported to the surface of the substrate, the growth of specific single crystal films.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

aluminium wires AA1050 with high purity and low price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches