All Categories

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

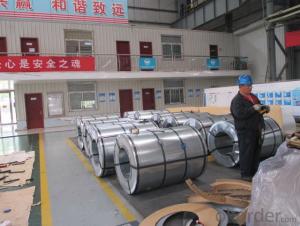

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Ceramic Fiber Products

- - Monolithic Refractories

- - Refractory Bricks

- - Raw Materials For Refractory

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the role of cold-rolled steel in the development of sustainable transportation solutions?

Cold-rolled steel plays a crucial role in the development of sustainable transportation solutions by providing a lightweight, durable, and energy-efficient material for vehicle manufacturing. Its high strength-to-weight ratio allows for the creation of lighter and more fuel-efficient vehicles, reducing carbon emissions and promoting sustainability. Additionally, cold-rolled steel's corrosion resistance ensures the longevity and recyclability of transportation infrastructure, further contributing to a sustainable transportation ecosystem.

What are the innovations in cold-rolled steel for use in the oil and gas industry?

There have been several innovations in cold-rolled steel for use in the oil and gas industry. These include the development of high-strength and corrosion-resistant grades of cold-rolled steel, which enhance the durability and longevity of equipment used in harsh environments. Additionally, advancements in cold-rolling technology have led to improved dimensional accuracy and surface quality, resulting in better performance and efficiency of oil and gas equipment. Furthermore, the use of advanced coatings and surface treatments on cold-rolled steel has increased its resistance to abrasion, wear, and chemical exposure, making it more suitable for demanding oil and gas applications. Overall, these innovations in cold-rolled steel have significantly contributed to enhancing the safety, reliability, and productivity of the oil and gas industry.

What is the impact of cold-rolled steel in the production of electrical wiring and cable systems?

The impact of cold-rolled steel in the production of electrical wiring and cable systems is significant. Cold-rolled steel is known for its superior strength, durability, and resistance to corrosion, making it an ideal material for manufacturing these critical components. It ensures the wiring and cable systems are able to withstand harsh environmental conditions, heavy usage, and provide reliable electrical conductivity. Additionally, the precise dimensions and smooth surface finish achieved through cold-rolling enhance the overall performance and longevity of the electrical systems, contributing to their efficiency and safety.

How is cold-rolled steel coated for specific applications?

Cold-rolled steel can be coated for specific applications through various methods such as electroplating, hot-dip galvanizing, and powder coating. These processes provide a protective layer on the steel surface, enhancing its corrosion resistance, durability, and aesthetic appeal.

Wholesale Cold Rolled Steel from supplier in Somalia

We are a Cold Rolled Steel supplier serving the Somalia, mainly engaged in the sale, quotation, and technical support services of various Cold Rolled Steel products in the Somalia region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Cold Rolled Steel procurement services in the Somalia. Not only do we have a wide range of Cold Rolled Steel products, but after years of market development in the Somalia, we can also provide valuable experience for your projects.