Timber Scaffolding Singapore

Timber Scaffolding Singapore Related Searches

Construction Glass Plastic Safety Netting Perri Construction Gas Fireplace Cover Replacements Collapsible Scaffolding Scaffolding Canada Fruit Foam Net Boat Propeller Cover Indoor Kerosene Heater Safety Geocomposite Drainage NetHot Searches

Scaffolding Manufacturer In Mumbai Physiotherapy Equipment Supplier In Malaysia Medical Equipment Suppliers In Kenya Electrical Equipment Price List Aluminium Scaffold Planks Sale Aluminium Walkway Mesh Prices Cost To Hire Scaffolding Scaffolding Sales Uk Scaffolding Manufacturers Uk Scaffolding Joints Types Scaffolding Bracing Types Scaffolding Types Ppt Scaffolding Company Names Harsco Scaffolding Company Wholesale Sound Equipment Electrical Equipment Company Petaluma Cleaning Equipment Suppliers Medical Equipment Suppliers Uk Rehabilitation Equipment Manufacturers Timber Greenhouses For SaleTimber Scaffolding Singapore Supplier & Manufacturer from China

Okorder.com is a professional Timber Scaffolding Singapore supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Timber Scaffolding Singapore firm in China.Hot Products

FAQ

- When it comes to selecting the right steel grade for formwork, there are several factors that need to be considered. First and foremost, the load-bearing capacity of the steel grade is of utmost importance. It must be able to withstand the weight and pressure exerted by the concrete and any additional loads during construction, while maintaining its structural integrity without any deformation or failure. Another crucial consideration is the corrosion resistance of the steel grade. Since formwork is often exposed to moisture and chemicals from the concrete, it is vital to choose a steel grade that can resist corrosion. This will ensure the longevity and durability of the formwork, avoiding any safety hazards or costly repairs. Furthermore, the ease of handling and fabrication is an important factor. The selected steel grade should be easy to cut, shape, and weld, allowing for efficient and accurate construction of the formwork. It should also have good dimensional stability, ensuring that the formwork remains in the desired shape and size during use. Cost-effectiveness is also a significant factor to consider. While it may be tempting to choose a higher grade steel with superior properties, it is important to evaluate the project requirements and select a grade that offers the necessary performance at a reasonable cost. This will help optimize the budget without compromising the quality and functionality of the formwork. Lastly, compliance with industry standards and regulations should not be overlooked. The selected steel grade must meet the relevant codes and specifications set by governing bodies to ensure that the formwork meets safety standards and can withstand the intended loads and environmental conditions. By considering these factors, one can choose an appropriate steel grade for formwork that provides structural stability, durability, corrosion resistance, ease of handling, cost-effectiveness, and compliance with industry standards.

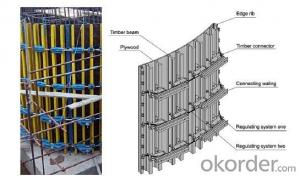

- Yes, steel formwork can be used for both flat and sloped surfaces. Steel formwork is a versatile and durable option for construction projects and can be easily adapted to form structures with various slopes. The flexibility of steel allows it to be bent or shaped to the desired angle, making it suitable for creating formwork for sloped surfaces. Additionally, steel formwork provides excellent support and stability, ensuring that the concrete is poured accurately and evenly on both flat and sloped surfaces. Its strength and rigidity make it a reliable choice for constructing formwork systems that can withstand the pressures exerted by the concrete during the casting process, regardless of the surface slope.

- Steel formwork can have a significant impact on the overall durability of a structure. Due to its inherent strength and durability, steel formwork provides excellent support and stability during the construction process. This ensures that the structure is built accurately and to the required specifications, which is crucial for long-term durability. One of the main advantages of using steel formwork is its ability to withstand high pressures and loads. This is especially important in large-scale construction projects where heavy concrete pours are involved. The steel formwork can effectively distribute the weight and pressure exerted by the concrete, preventing any deformation or collapse. This ensures that the structure retains its integrity and remains durable over time. Additionally, steel formwork is highly resistant to environmental factors such as moisture, humidity, and temperature variations. This resistance helps protect the structure from potential damage caused by these factors, such as corrosion, rot, or warping. As a result, the overall durability of the structure is enhanced, ensuring its longevity and minimizing the need for costly repairs or maintenance. Furthermore, steel formwork provides a smooth and even surface for the concrete to adhere to during the curing process. This results in a uniform and consistent finish, reducing the risk of cracks or weak points in the structure. The absence of such defects improves the overall durability of the structure, as it is less prone to structural weaknesses that can compromise its integrity over time. Moreover, steel formwork is reusable and can be easily dismantled and reassembled for multiple construction projects. This not only reduces construction costs but also minimizes waste and environmental impact. The ability to reuse steel formwork ensures that the structure is built with high-quality materials consistently, contributing to its long-term durability. In conclusion, steel formwork significantly affects the overall durability of a structure. Its strength, resistance to environmental factors, ability to distribute loads, and provision of a uniform finish all contribute to the long-term durability and structural integrity of the building. By using steel formwork, builders can ensure that the structure is built to last, minimizing the need for repairs or replacements in the future.

- Steel formwork can have a significant impact on the overall construction cost. While it may have a higher upfront cost compared to other formwork materials like timber or plywood, steel formwork offers durability and reusability, resulting in reduced material and labor expenses for future projects. Additionally, its strength and stability allow for faster construction cycles, reducing labor costs and improving overall efficiency. So, although the initial investment may be higher, the long-term benefits and cost savings associated with steel formwork make it a cost-effective choice for construction projects.

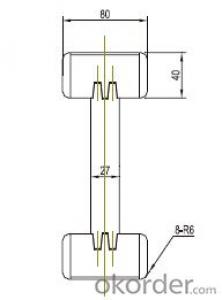

- When selecting the size and spacing of steel formwork panels, several considerations need to be taken into account. First, the size of the panels should be determined based on the dimensions of the concrete structure being formed. The panels should be able to accommodate the desired shape and size of the concrete element. Secondly, the spacing between the panels should be chosen to ensure adequate support and stability. The spacing should be determined based on the load-bearing capacity of the panels and the weight of the concrete being poured. It is important to have proper spacing to prevent deflection or deformation of the formwork. Additionally, the size and spacing of the panels should also consider the ease of handling and installation. Panels that are too large or heavy may be difficult to transport and assemble, leading to time and labor inefficiencies. On the other hand, panels that are too small may result in excessive joints, increasing the chances of leakage or misalignment. Overall, the selection of the size and spacing of steel formwork panels should prioritize structural integrity, functionality, and ease of use to ensure successful and efficient concrete formwork construction.

- There are several common durability issues that can arise with steel formwork systems. One of the main concerns is corrosion, which occurs when the steel comes into contact with moisture or aggressive chemicals. Corrosion can weaken the structural integrity of the formwork system and lead to premature failure if not properly addressed. Another durability issue is wear and tear. Steel formwork systems are often subjected to repeated use, which can result in surface damage and deformation over time. This can lead to difficulties in achieving accurate and precise concrete finishes, as well as pose safety risks for workers. Additionally, improper handling and storage of steel formwork systems can result in bending or warping of the components. This can affect the overall stability and effectiveness of the system, making it less durable and reliable. Finally, inadequate maintenance and lack of proper protective coatings can contribute to durability issues. Regular inspections, cleaning, and applying protective coatings can help prevent corrosion and extend the lifespan of the steel formwork system. In conclusion, common durability issues with steel formwork systems include corrosion, wear and tear, improper handling and storage, and inadequate maintenance. It is crucial to address these issues promptly and implement proper maintenance practices to ensure the longevity and effectiveness of the formwork system.

- Are all steel plates used for beam slab prefabrication

- Should be determined according to the shape of the prefabricated components, specifications, to facilitate construction, cost savings, to ensure the quality of the premise.