Tiffany Ceiling Light

Tiffany Ceiling Light Related Searches

Best Inverter For Solar System Led Light For Chandelier Decorative Ceiling Plate For Light Fixture Inverter For 5kw Solar System Parts For Light Fixtures Transformer For Light Fixture Decorative Lights For Ceiling Lights For Kitchen Ceiling Ceiling Brackets For Lights Hanging Ceiling Chairs For BedroomsHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Plate For Sale Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Aluminum Bar Stock For SaleTiffany Ceiling Light Supplier & Manufacturer from China

Okorder.com is a professional Tiffany Ceiling Light supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Tiffany Ceiling Light firm in China.Hot Products

FAQ

- What is the difference between light steel keel and aluminum alloy keel?

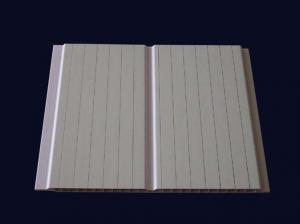

- Light steel keel is generally used in the veneer, that is, keel seal gypsum board in the paint, aluminum alloy in the frame of the more, paint keel, aluminum, mineral wool board.

- I would rather not drywall the ceiling to provide future access to wiring and ductwork. What could be used to reduce overall noise? I am most concerned about the master bedroom, which is right above the area being finished, as there will be a home theatre system installed.

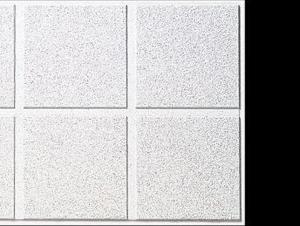

- Definately go with a suspended acoustical ceiling. It muffles noise, is easy to install, and you can set fluorescent light fixtures into the grid. The article Install a Suspended Grid Ceiling on the following link, tells you just how to do it, step by step.

- The old ceiling that is there is holding all the blown in, insulation.

- Yes, if the ceiling/roof appears structurally sound for the added weight. I would use lighter weight thin drywall with screws into the ceiling framing with glue also.

- Light steel keel hanging shed, a day of work can work out how much work?

- Different construction requirements, construction conditions, the skilled proficiency of workers and other factors, will affect the construction of the workload of the number. In addition, the shape of the ceiling, the amount of live will be subject to constraints

- In the CAD 'light steel keel seal 18 PCT big core board posted 8 PCT car side gray paint glass' What is the meaning of this sentence? Request to say the details of the point yo.

- Hanging light steel, do not hang gypsum board, hanging big core board to do the foundation, Daixin board paste gray paint glass. Good bizarre decoration process ah

- Fixed in the light steel keel h19 what it means

- Flat roof if the level of the width of the width of 300mm between the expansion area can be calculated by the same material can be combined with the amount of calculation, which refers to the width of the horizontal distance. The difference between the height should be the vertical height difference, the calculation of the rules described> 300mm width can be calculated by the expansion area, the expansion of the vertical height size.

- 60 series of light steel keel, 12 thick single layer of paper gypsum board "which" 60 series light steel keel "What is the meaning of the project. Is the main keel, vice keel are 60 series? Or only refers to the main keel 60 series, vice keel 50 series? Thank you

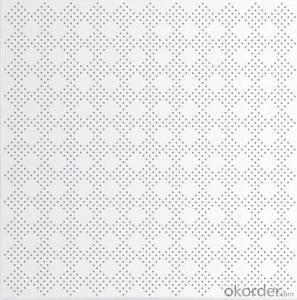

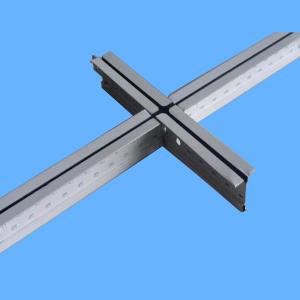

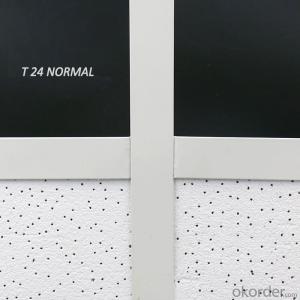

- Quality identification of light steel keel ??Light steel keel according to the use of hanging keel and cut keel, according to cross-section of the form of V-type, C-type, T-type, L-keel. (1) product specifications series ?The main specifications of the keel are divided into Q50, Q75 and Q100. The main specifications of the ceiling keel are divided into D38, D45, D50 and D60. (2) product marking method Light steel keel mark the order of the order: product name, code, cross-sectional shape of the width, height, plate thickness and standard number. Such as cross-sectional shape of "C" type, width of 50mm, height of 15mm, steel plate thickness of 1. Smm of the ceiling keel marked as: building light steel keel DC 5 0 XIS XISGBllg sl (3) appearance quality Light steel keel shape to smooth, angular, cut not allowed to affect the use of burrs and deformation. Galvanized layer is not allowed to skin, from the tumor, shedding and other defects. For corrosion, damage, dark spots, pitting and other defects, according to the provisions of the method should be tested in accordance with the provisions of Table 2-81. ?Appearance quality inspection, should be 0.5m away from the product under the conditions of bright light, the visual inspection. ?Light steel keel surface should be galvanized rust, the double-sided galvanized: excellent products not less than 120g / m * m, first-class goods is not less than 100g / m * m, qualified products not less than 80g / m * m.

- Ceiling tiles, ceiling grid - any regulations on materials, surface, etc.

- I wouldn't use ceiling tiles at all. Basically, you don't want anything that could crumble and fall in to food. Things to consider in food plant design 1) Nothing extra gets into the food. (falling, crumbling, chipping etc. this includes building materials, dust, animal droppings, etc.) 2) germs (all sorts) are not allowed to grow. Design the surfaces to be cleaned with air. Germs love water and no matter how much you try you won't be able to completely dry something immediately after it's wetted. Don't give the little nasties places to grow.