Thickness Of Checkered Plate

Thickness Of Checkered Plate Related Searches

Shiny Or Dull Side Of Aluminum Foil For Cooking Inverter For 100w Solar Panel Solar Panel Inverter For Rv Pvc Tiles For Walls Wall Lights For Bedrooms Inverter Ac With Solar Panel Solar Panel With Inverter Kit Solar Panel Kits With Inverter Solar Panel With Inverter Direct Roving For PultrusionHot Searches

Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Used Sandwich Panel For Sale Bags Of Cement For Sale Pvc Chairs For Sale Tilt Panel Props For Sale Types Of Temporary Side Panels For Cement Deck Cost Of Awnings For Decks Type Of Scaffolding With Pdf Price Of Scrap Stainless Steel Price Of Stainless Steel Scrap Price Of Stainless Steel Type Of Stainless Steel Types Of Stainless Steel Grades Types Of Stainless Steel China Aluminum Coil Factory pvc pipe manufacturers in usa Sandwich Panel Price In India Aluminum Corp Of China StockThickness Of Checkered Plate Supplier & Manufacturer from China

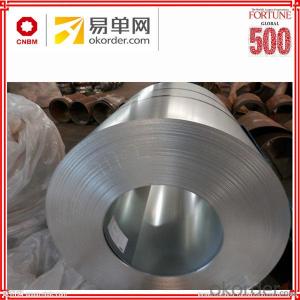

Okorder.com is a professional Thickness Of Checkered Plate supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Thickness Of Checkered Plate firm in China.Hot Products

FAQ

- Steel sheets resist fire due to their high melting point and excellent heat conductivity. When exposed to fire, the steel sheets absorb and conduct heat away from the source, preventing the temperature from rising to a critical level where the steel would weaken or melt. Additionally, steel does not combust or release toxic gases when heated, further enhancing its fire resistance.

- A steel sheet and a steel plate have a few key differences. Firstly, the thickness of a steel sheet is generally less than 6mm, while a steel plate is typically thicker and measures 6mm or more. This difference in thickness is primarily due to the intended use of each product. Steel sheets are often used in applications where weight and flexibility are important, such as in the manufacturing of automobile bodies or appliances. On the other hand, steel plates are commonly utilized in heavy-duty constructions, such as bridges, buildings, or machinery, where strength and durability are paramount. Another difference lies in the manufacturing process. Steel sheets are typically produced through hot rolling, which involves heating the steel above its recrystallization temperature and then passing it between rollers to achieve the desired thickness. Steel plates, on the other hand, can be produced through hot rolling or cold rolling processes. Cold rolling involves passing the steel through rollers at room temperature, resulting in a more precise and smoother surface finish. Additionally, the size of steel sheets and plates also varies. Steel sheets tend to be standardized in terms of width and length, making them easier to handle and transport. Steel plates, on the other hand, are available in various sizes and dimensions, allowing for greater customization to suit specific project requirements. In summary, the primary differences between a steel sheet and a steel plate lie in their thickness, manufacturing process, and intended use. While steel sheets are thinner and more lightweight, steel plates are thicker and employed in heavy-duty applications that require strength and durability.

- No, steel sheets cannot be used for insulation as they conduct heat and do not possess insulating properties.

- Yes, steel sheets generally require surface treatment before installation to prevent corrosion, improve paint adhesion, and enhance their overall durability and longevity. Common surface treatments include cleaning, degreasing, priming, and applying protective coatings such as galvanizing or powder coating.

- Steel sheets are an excellent choice for shipbuilding due to their suitability and versatility. This durable material possesses exceptional properties for marine applications. Its high strength-to-weight ratio allows for the construction of sturdy vessels while maintaining a low overall weight. Furthermore, steel sheets have impressive tensile strength, ensuring the ship's structural integrity and resistance against external forces like waves, wind, and other factors. The corrosion-resistant nature of steel makes it particularly ideal for enduring the harsh saltwater environment. Additionally, its fire-resistant properties further enhance the safety of ships. Consequently, steel sheets are extensively utilized in shipbuilding and have demonstrated reliability and efficiency in constructing various types of vessels, including cargo ships, cruise liners, and naval warships.

- The different grades of steel used for sheets vary depending on factors such as strength, durability, and corrosion resistance. Some common grades include carbon steel (e.g., A36), stainless steel (e.g., 304 or 316), and high-strength low-alloy steel (e.g., A572). Each grade has specific properties that make it suitable for various applications in industries like construction, automotive, and manufacturing.

- The hardness of steel sheets can vary depending on the specific grade and treatment of the steel. Steel sheets are typically measured on the Rockwell hardness scale, which measures the resistance of the material to indentation. The hardness of steel sheets can range from relatively soft to extremely hard, depending on factors such as the carbon content, alloying elements, and heat treatment processes used during manufacturing. It is important to consider the intended application and desired properties when selecting steel sheets, as the hardness can affect factors such as wear resistance, strength, and machinability.

- Yes, steel sheets can be used for industrial machinery or equipment. Steel sheets are commonly used in the manufacturing and construction industries due to their strength, durability, and versatility. They can be fabricated into various shapes and sizes to suit the specific requirements of different machinery or equipment, making steel sheets a reliable choice for industrial applications.