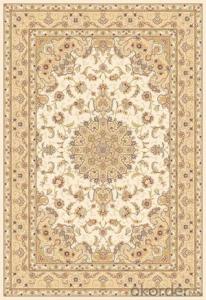

Rug Yarn

Rug Yarn Related Searches

2 Inch Styrofoam Insulation Sheets Home Insulation Contractors Indoor Window Insulation Urethane Insulation Panels Fine Home Textiles Classic Wood Furnace Expanded Perlite Insulation Blown Insulation Calculator Cavity Insulation Polyisocyanurate InsulationHot Searches

Thermal Coal Spot Price Australian Thermal Coal Price Rocksol Insulation Cost Cement Fibre Cladding PricesRug Yarn Supplier & Manufacturer from China

Okorder.com is a professional Rug Yarn supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Rug Yarn firm in China.Hot Products

FAQ

- Yes, fiberglass yarn can be used for making swimwear. Fiberglass is a strong and durable material that is resistant to water and chemicals. It can provide excellent support and shape retention, making it ideal for swimwear. Additionally, fiberglass yarn is lightweight and has a smooth surface, providing a comfortable and sleek fit. However, it is important to note that fiberglass can be irritating to the skin, so proper lining or coating may be necessary to ensure comfort and safety.

- Indeed, when fiberglass yarn is confronted with high temperatures, it undergoes shrinkage. The process of creating fiberglass involves melting glass and subsequently transforming it into delicate fibers, which are then interwoven to form yarn. Once exposed to heat, the glass fibers within the yarn contract and diminish in size. Consequently, the yarn's length and diameter may experience a reduction. Therefore, one must take into account this phenomenon of shrinkage when utilizing fiberglass yarn in situations where elevated temperatures are anticipated, as it could potentially affect the material's performance and dimensional stability.

- Fiberglass yarn is generally not suitable for 3D printing. While fiberglass itself is a strong and lightweight material, it poses several challenges when used in 3D printing processes. One major issue is the high melting point of fiberglass, which is typically around 700-800 degrees Celsius. This temperature is significantly higher than what most 3D printers are capable of reaching, as the common filaments used in 3D printing, such as PLA or ABS, have much lower melting points. Moreover, fiberglass is also prone to breakage and can be abrasive, which can cause damage to the extruder nozzle or other components of a 3D printer. This can result in clogging or other printing issues that hinder the quality and reliability of the printed object. Additionally, the fine fibers of fiberglass yarn can pose health risks if released into the air during printing, as they can be inhaled and cause irritation or damage to the respiratory system. Therefore, while fiberglass yarn may offer desirable properties for certain applications, it is generally not recommended for use in 3D printing due to its high melting point, potential for damaging the printer, and health concerns. Other filaments specifically designed for 3D printing, such as PLA or ABS, are more suitable and widely used in the industry.

- Yes, fiberglass yarn can be used in shipbuilding. It is often used for reinforcing structures and components in boats and ships, as it is lightweight, sturdy, and resistant to corrosion and water damage.

- Indeed, outdoor applications can utilize fiberglass yarn. Fiberglass possesses a reputation for its resilience and ability to withstand various weather conditions, rendering it fitting for outdoor utilization. In the construction domain, it is frequently employed to reinforce concrete and manufacture items like roofing materials, awnings, and outdoor furniture. The innate characteristics of fiberglass, including its robustness, non-corrosive nature, and capacity to endure extreme temperatures, position it as an optimal material for outdoor applications that demand durability and longevity.

- Yes, fiberglass yarn can be used for reinforcement purposes. Fiberglass yarn is known for its high strength and durability, making it an ideal material for reinforcing various products and materials. It is commonly used in the construction industry to reinforce concrete, as well as in the production of fiberglass composites for applications such as automotive parts, boat hulls, and aerospace components. Fiberglass yarn can also be used to reinforce fabrics, ropes, and cables, providing them with increased strength and resistance to tearing or breaking. Overall, fiberglass yarn is a versatile material that can effectively enhance the mechanical properties of various products when used for reinforcement purposes.