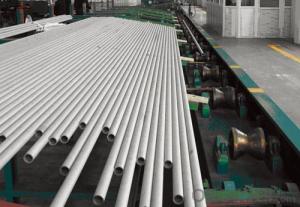

Pipe Stainless

Pipe Stainless Related Searches

Flexible Steel Pipe Aluminum Pipe Stock Perforated Pvc Pipe Small Bore Plastic Pipe Bondstrand Fiberglass Pipe Pipe Insulation Wrap 18 Heavy Duty Aluminum Foil 24 Heavy Duty Aluminum Foil Heavy Gauge Aluminum Foil Heavy Duty Aluminum FoilHot Searches

Steel Mesh Panels For Sale Cheap High Tea Sets For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For Sale Large Led Screens For Sale 1/4 Aluminum Plate For Sale Passive Solar Water Heater For Sale H4 Led Headlight Bulbs For Sale Air Pump For Aquarium Price Inverter Size For Solar System Solar Edge Inverter For Sale 5kw Solar Inverter For Sale Printed Solar Cells For SalePipe Stainless Supplier & Manufacturer from China

Okorder.com is a professional Pipe Stainless supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Pipe Stainless firm in China.Hot Products

FAQ

- Stainless steel pipes have the capability to undergo coating procedures. Coating these pipes serves multiple purposes, such as bolstering their durability, preventing corrosion, providing insulation, and enhancing their aesthetics. There exist diverse options for coating stainless steel pipes, including epoxy coatings, polyurethane coatings, and fusion-bonded epoxy coatings. These coatings are applied to the surface of the stainless steel pipes using various techniques, such as spraying, dipping, or electrophoretic deposition. The selection of the appropriate coating relies on the specific requirements of the application and the environment in which the pipes will be utilized. By coating stainless steel pipes, their lifespan can be significantly extended and their performance can be improved, making them suitable for a wide range of industries including oil and gas, chemical, water treatment, and construction.

- Yes, stainless steel pipes can be used for pharmaceutical manufacturing. Stainless steel is a commonly used material in the pharmaceutical industry due to its excellent corrosion resistance, high strength, and ease of sterilization. It is suitable for transporting various pharmaceutical fluids and gases while ensuring cleanliness, safety, and compliance with industry regulations.

- Indeed, it is possible to bend stainless steel pipes. Stainless steel, being an incredibly versatile material, possesses remarkable strength and ductility, enabling it to undergo bending without any risk of breakage or cracking. To achieve the desired outcome, the bending process employs a variety of techniques, including cold bending, induction bending, or hot bending, depending on the pipe's thickness and the desired outcome. With the ability to be bent to different angles and shapes, stainless steel pipes find themselves well-suited for a broad range of applications in construction, plumbing, and the automotive industry. Nonetheless, it is vital to emphasize that professionals or specialized equipment must be employed to carry out the bending process, ensuring the stainless steel pipes' structural integrity and overall quality.

- In order to determine the flow rate in stainless steel pipes, one can utilize the principles of fluid dynamics along with the properties of the fluid being conveyed through the pipe. There are several factors which must be taken into account: 1. The first step is to ascertain the diameter of the pipe. This parameter significantly impacts the flow rate as a larger diameter allows for a greater volume of fluid to pass through. 2. The second step involves determining the viscosity of the fluid. Viscosity refers to the fluid's resistance to flow. Fluids with high viscosity flow at a slower rate, whereas those with low viscosity flow more rapidly. 3. The next consideration is the calculation of the pressure drop across the pipe. This factor plays a crucial role in establishing the flow rate, and it can be computed by measuring the pressure at different points along the pipe. 4. The Reynolds number is then employed. This dimensionless value combines the fluid's velocity, density, viscosity, and pipe diameter. It aids in determining whether the flow is laminar (smooth) or turbulent (chaotic). Different equations exist to calculate the Reynolds number based on the flow regime. 5. The final step involves the application of the appropriate flow equation. Depending on the flow regime, various equations can be utilized to calculate the flow rate. For laminar flow, the Hagen-Poiseuille equation is applicable, while the Darcy-Weisbach equation or the Manning equation can be employed for turbulent flow. By considering these factors and employing the appropriate equations, the flow rate in stainless steel pipes can be determined. It is important to note that these calculations provide an estimate and may not yield exact results due to factors such as pipe roughness, fittings, and other obstructions within the pipe. Therefore, it is advisable to consult a fluid dynamics expert or employ specialized software for accurate calculations.

- Certainly! Stainless steel pipes are suitable for underground sewer lines. Due to its remarkable durability and resistance to corrosion, stainless steel is an optimal material selection for harsh environments, including underground sewer systems. It offers exceptional protection against chemicals, moisture, and other corrosive elements frequently encountered in sewer lines. Moreover, stainless steel pipes boast an extended lifespan and necessitate minimal upkeep, proving to be an economical choice over time. Nevertheless, it is crucial to account for the particular specifications and regulations of the local sewer system before opting for stainless steel pipes in underground applications.

- Ask experts, 304 stainless steel pipe why rust?

- 304 stainless steel is a common stainless steel material, the density of 7.93 g/cm3, the industry is also called 18/8 stainless steel. High temperature resistance of 800 degrees, with good processability, high toughness characteristics, widely used in industry and furniture decoration industry and food and medical industry.The common marking methods in the market are 06Cr19Ni10, SUS304, in which 06Cr19Ni10 is generally used to indicate standard production of the national standard. Generally speaking, ASTM standard production is indicated, and SUS 304 represents standard production.304 is a versatile stainless steel which is widely used in the manufacture of equipment and parts requiring good overall performance (corrosion resistance and formability). In order to maintain the inherent corrosion resistance of stainless steel, steel must contain more than 18% chromium, more than 8% of the nickel content. 304 stainless steel is a brand of stainless steel produced according to the ASTM standard in the United states.

- Indeed, agricultural irrigation systems can utilize stainless steel pipes. With its exceptional durability and resistance to corrosion, stainless steel proves to be an appropriate material for a wide range of purposes, including agricultural irrigation. Its remarkable ability to withstand rust and corrosion, even when faced with moisture, chemicals, and fertilizers commonly employed in irrigation systems, is well-known. Furthermore, stainless steel pipes possess the capability to endure high-pressure water flow, enabling them to efficiently deliver water to crops. Notably, stainless steel is environmentally conscious, being entirely recyclable, which renders it a sustainable option for agricultural irrigation systems.

- The main difference between 2205 and 2507 stainless steel pipes lies in their chemical composition and corrosion resistance. While both are duplex stainless steels, 2205 contains 22% chromium, 5% nickel, and 3% molybdenum, whereas 2507 contains 25% chromium, 7% nickel, and 4% molybdenum. This difference in composition provides 2507 with slightly higher corrosion resistance, especially in environments with high levels of chloride ions. Additionally, 2507 stainless steel pipes offer better strength and impact toughness compared to 2205. Consequently, 2507 is often chosen for applications that require enhanced resistance to corrosion and higher strength.