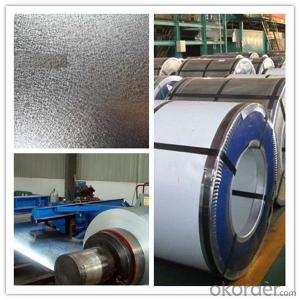

Hot Dip Galvanized Steel

Hot Dip Galvanized Steel Related Searches

Best Paint For Stainless Steel Paint For Galvanized Steel Steel Frames For Furniture Self Tapping Screws For Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For Bbq Step Bit For Stainless Steel Sponge For Stainless SteelHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For SaleHot Dip Galvanized Steel Supplier & Manufacturer from China

Okorder.com is a professional Hot Dip Galvanized Steel supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Hot Dip Galvanized Steel firm in China.Hot Products

FAQ

- The yield strength of steel coils can vary depending on the specific grade and composition of the steel. However, the typical yield strength of steel coils ranges from 300 to 600 megapascals (MPa).

- Steel coils can be significantly affected by global trade policies. Trade policies, such as tariffs and quotas, can impact the import and export of steel coils, influencing their availability and pricing in different markets. Changes in trade policies can lead to shifts in supply and demand, affecting the volume and cost of steel coil imports and exports. Additionally, trade policies aimed at protecting domestic industries may create barriers for steel coil imports, potentially affecting the competitiveness of steel coil manufacturers and suppliers.

- which elements are alloyed to make stainless steel?A Fe, CB Fe, MnC Fe, NiD Fe, CrE Fe, Cr, Ni

- E. Stainless steel is mainly comprised of Cr and Ni. Steel is an alloy composed mainly of iron. On a side note, Carbon is not really in stainless steel and it is only less than .1%

- I plan to buy a bushcraft knife ..The blade made up by damascus steel.My question is ,is damascus steel is very strong ?

- So, there isn't a good answer to your question, because Damascus doesn't describe the actual materials properties of the steel, rather the mechanical construct of the steel. For example: A very common Damascus steel is to layer L6 with 1080 high carbon steel and forge weld the layers together to make a blank, anneal it, then grind it into your blade and heat treat it. (Massive over simplification) That type of Damascus steel is going to be a bit softer than one of the super high carbon exotics, but will be tougher in terms of ability to flex without taking a set, and not chipping out if the edge hits something hard. (assuming it is heat treated well) - edge between RC56 - 58 typically. Another common Damascus steel is layers of VG-10 steel and VG-1 steel also welded together, with the billet then annealed, ground, and heat treated. In this case, because you are using stainless steels you will get a much harder edge - RC 60 - 62 typically. It will have better toughness than plain VG-10, but certainly nowhere near what you can get out of L6 or 52100 or something of that sort. Generally, for a bushcraft knife you typically want something like the first type of Damascus because you are looking for a more all purpose tool, and typically a larger knife. The only problem is that in the bush the first types of steel typically rust. The second type is made up of stain resistant steels and will hold up better. So, this brings me around to - why exactly do you want a Damascus blade on your knife? Are you already looking at one you like? Thinkingblade

- Is the product of mild steel environmentally friendly? does it produce any emissions?The same question for leather aswell.

- Steel just rusts, it doesn't produce any emissions just sitting there. They even make architectural steel called Corten to rust to a nice patina. If you consider how the steel was made in the first place, a great big NO! Steel making requires massive amounts of electricity plus it gives off some nasty fumes in the liquid state. Leather itself doesn't emit much of anything, but the dyes might. Again though, if you look at how it's made, tanning leather is right up there with steel mills and paper mills for pollution, some of the worst.

- I need to identify a metal. It is rusty so I suspect it is either iron or steel. Since they both have similar densities and are magnetic, how do I tell the difference betweeen steel and iron?

- Iron and Steel Manufacture, technology related to the production of iron and its alloys, particularly those containing a small percentage of carbon. The differences between the various types of iron and steel are sometimes confusing because of the nomenclature used. Steel in general is an alloy of iron and carbon, often with an admixture of other elements. Some alloys that are commercially called irons contain more carbon than commercial steels. Open-hearth iron and wrought iron contain only a few hundredths of 1 percent of carbon. Steels of various types contain from 0.04 percent to 2.25 percent of carbon. Cast iron, malleable cast iron, and pig iron contain amounts of carbon varying from 2 to 4 percent. A special form of malleable iron, containing virtually no carbon, is known as white-heart malleable iron. A special group of iron alloys, known as ferroalloys, is used in the manufacture of iron and steel alloys; they contain from 20 to 80 percent of an alloying element, such as manganese, silicon, or chromium.

- Have spent two days making a specialized knife out of 304 stainless steel, after throwing into a log it bent slightly arghhhh. Is it worth continuing to finish it off or start all over again with different kind of steel if so which kind should i use.

- Sorry okorder /... I hope that link works but as you can see you dont want to use 303.304.316,410,416,430 You can get away with 301 but would be best to use 440. It kind of sounds like your a home shop guy. It would be best for you to make a knife out of a1 or d2 tool steel. with these steels you can torch heat them to a red hot heat where a magnet will not stick to them. Then let them cool slowly in the air. After that you can temper in a oven around 400f. This will a very hard long lasting knife. Check OKorder for good steel prices. A1 and D2 are not stainless but they are the best for a home shop. If you go stainless you can buy preharden material but you will have to grind everything. You can also pay someone to harden your knife but dont plan on it being cheap.

- Guitar?I have a steel- string, but prefer nylon.:)

- As people say, nylon strings are (generally) for classical/spanish acoustic guitars - put steel on those and goodbye guitar; the neck will bow and can break.. On other guitars then steel is what you need - if you put nylon on you will have no sustain and tonality. A reasonable guide is the string winding mechanism of the classical guitar. Actually, steel is a pretty much generic term as lots of steel strings are now coated or wound with bronze or phosphor-bronze etc. Strings also come in different gauges or thicknesses depending on what you play. Lighter strings are best for finger-picking and heavier for strumming. Electric guitar strings tend to be strung lighter than acoustic. Finally, a guitar is built for a certain string gauge. If you put strings on that are too light then you may get fret buzz but if you put strings on that are too heavy you could bow the neck of the guitar.