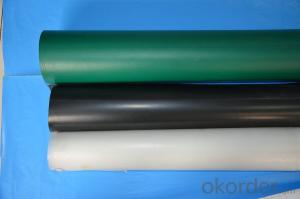

Geomembrane India

Geomembrane India Related Searches

Blu Ray Player With Internet Geomembrane In Pakistan 30 Mil Pvc Geomembrane Pvc Geomembrane Specifications Pvc Geomembrane Geomembrane Machine Plastic Geomembrane Nonwoven Wallpaper Geomembrane Material Geomembrane FabricHot Searches

Geomembrane For Sale China Pvc Geomembrane China Geomembrane Roll Sheet Hdpe Geomembrane Sheet Price Hdpe Geomembrane China China Geomembrane Geomembrane China Hdpe Geomembrane Price Geomembrane Price Wholesale Hdpe Geomembrane Roll Geomembrane Factory Wholesale Liner Hdpe Geomembrane Wholesale Geomembrane Hdpe Wholesale Hdpe Geomembrane Geomembrane Market Size Wholesale Hdpe Geomembrana Wholesale Liner Geomembrane Geomembrane Liner Supplier Wholesale Geomembrane China Pvc GeomembraneGeomembrane India Supplier & Manufacturer from China

Okorder.com is a professional Geomembrane India supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geomembrane India firm in China.Hot Products

FAQ

- Geomembranes are a modern alternative to traditional clay liners and offer several advantages. Unlike clay liners, geomembranes are made from synthetic materials like HDPE or PVC, making them more consistent in terms of quality and performance. Geomembranes are also easier to install and maintain, and they have a higher resistance to chemical degradation and puncture. Furthermore, geomembranes can provide a more effective barrier against seepage and leakage, reducing the risk of environmental contamination. Overall, geomembranes offer superior performance, durability, and convenience compared to traditional clay liners.

- nan

- Moistureproof membranes, just as the name suggests, apart from preventing moisture, they can also prevent bugs from burrowing and biting.

- nan

- The testing standards of geomembrane: 1. GM1 ultrasonic method evaluation joint 2. GM2 anchoring movement insert depth 3. GM3 large-scale hydrostatic force anti-puncture test (see ASTM D5514) 4. GM4 three-dimensional geomembrane tensile test (see ASTM D5617) 5. GM5 (a) polyolefin resin or geomembrane notched constant tensile load (NCTL) test (1992) (see ASTM D5397) 6. GM5 (b) polyolefin resin or geomembrane single point NCTL test (see Appendix ASTM D5397 ) 7. GM5 (c) polyolefin geomembrane joint joint constant tensile load (SCTL) test 8. GM6 dual-channel joint geomembrane high-pressure airway test 9. GM7 chemical welding method geomembrane joint peeling accelerated solidification test 10.GM8 quarry-faced geomembrane core layer thickness measurement (see ASTM D5994) 11.GM9 geomembrane low temperature joint 12.GM10 HDPE geomembrane sheet stress cracking resistant standard 13. GM11 conduct geomembrane accelerated aging test with fluorine light irradiation device 14. GM12 measure the roughness of quarry-faced geomembrane with depth?indictor 15. GM13 high density polyethylene (HDPE) geomembrane test characteristics, test frequency and recommendation guarantee 16. GM14 take samples and choose a variety of intervals for geomembrane non-destructive test joint samples with characteristic test method 17. GM15 confirm bonding between layers of reinforced geomembrane 18. GM16 geomembrane surface cracking observation 19. GM17 linear low density polyethylene (LLDPE) geomembrane with smooth and rough surfaces test characteristics, test frequency and recommendation guarantee 20, GM19 LLDPE HDPE welding shear peel strength

- nan

- Paper cups coated with single-sided laminated film are used to contain hot drinks while paper cups coated with double-sided laminated film contain cold drinks. The double-sided laminating paper cup has a layer of transparent film on its both sides and the cup is smooth.

- nan

- The geotechnical membrane is made of plastic film as the impervious material, and the composite of the non-woven fabric is made of the soil anti seepage material.

- nan

- One is GB 1st type

- Geomembranes help in groundwater recharge projects by acting as a barrier to prevent the loss of water through seepage and infiltration. They are used to line the recharge basins or ponds, ensuring that the water is effectively contained and slowly percolates into the ground, replenishing the groundwater reserves. This not only helps to conserve water but also prevents contamination and ensures the efficient recharge of aquifers.

- Geomembranes prevent contamination of soil and water by acting as a barrier between potentially harmful substances and the surrounding environment. These impermeable synthetic materials are designed to prevent the migration of contaminants, such as chemicals or pollutants, from reaching the soil or water below. By effectively isolating the contaminants, geomembranes help protect the integrity of the soil and water, ensuring their purity and preventing any adverse effects on the surrounding ecosystem.