Geocomposite Drain

Geocomposite Drain Related Searches

Geocomposite Sheet Drain Black Clay Roof Tiles Geocomposite Drainage Material Grey Clay Roof Tiles Geosynthetic Fabric Clay Roof Tiles Roof Tiles Clay 40 Mil Hdpe Liner Geocomposite Drainage Mat Geocomposite Strip DrainHot Searches

Geocomposite Manufacturers Wholesale Liner Hdpe Geomembrane Wholesale Hdpe Geomembrana Hdpe Geomembrane Liner Manufacturers Hdpe Liner Cost Hdpe Pond Liner Specifications Geosynthetic Clay Liner Cost Landfill Liner Cost Geocomposite Manufacturers Roof Clay Tiles Prices Hdpe Liner Cost Geosynthetic Clay Liner Cost Landfill Liner Cost Geocomposite ManufacturersGeocomposite Drain Supplier & Manufacturer from China

Okorder.com is a professional Geocomposite Drain supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geocomposite Drain firm in China.Hot Products

FAQ

- 300g / m2 geotextile package is what it means

- 300g / m2 Geotextile: refers to the weight of 300g per square meter (model) 300g / m2 geotextile package: refers to the outsourcing; with 300g of geotextile to wrap something; for example: With 300g / m2 geotextile wrapped gravel. The

- Do you have to have a mattress on the geotextile?

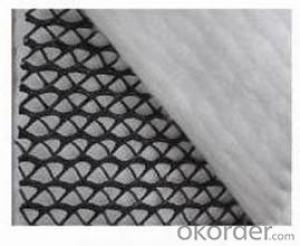

- 1, geotextile must be washed back to fill or sand protective layer and light compaction to prevent the subsequent construction of the destruction of geotextile, punctured and so on. But also a transition zone, to ease the upper load on the geotextile extrusion, tensile force and so on. 2, "Geotextile Construction Code QB / SNGSG-2004" and "Geosynthetics Application Technical Specifications GB / T-2017" backfill requirements: 1) timely backfill materials, backfill stone maximum drop of not more than 300mm, Heavy earth stones should not roll on the slope of the rolling; 2) fill the compaction should meet the design requirements, backfill 300mm loose layer, light compaction. 3, geotextile introduction: 1), geotextile by synthetic fiber through acupuncture or weaving made of permeable geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Advantages: geotextile with excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with a light weight, high tensile strength, good permeability, high temperature, resistance to Freezing, anti-aging, corrosion-resistant advantages. 2), Disadvantages: in the rigid base waterproof requirements are not applicable (tensile rate does not meet the requirements), easy to break, scratches and so on.

- Geotextiles help prevent soil erosion in vineyards by providing a protective barrier between the soil and external factors such as rain, wind, and water runoff. These textile materials effectively stabilize the soil by minimizing surface erosion, controlling sediment movement, and promoting the retention of moisture. Additionally, geotextiles enhance soil structure and allow for better root growth, preventing the loss of valuable topsoil and preserving the vineyard's overall health and productivity.

- Geotextiles improve the performance of pavement structures by providing reinforcement, filtration, and separation functions. They enhance the pavement's strength and stability by distributing the load more evenly, reducing rutting and cracking. Additionally, geotextiles help to prevent the mixing of different soil layers, minimizing the potential for contamination and maintaining the long-term integrity of the pavement.

- Yes, geotextiles can be used in the construction of reservoirs. Geotextiles are commonly used in civil engineering projects, including reservoir construction, to provide filtration, separation, and reinforcement. They can be used to prevent soil erosion, stabilize slopes, and enhance the overall performance and longevity of reservoir structures.

- Seepage geotextile and impervious geomembrane

- It is generally believed that the individual geotextile does not have the anti-seepage effect, the main assessment index is the permeability coefficient, the general geotextile coefficient is higher than the ordinary soil, about 0.01-0.001 look, but the geotextile and rubber, Asphalt, plastic combination will form a water-impermeable composite, anti-seepage effect increased by 10 times, and asphalt, rubber combined into a waterproofing membrane such as sbs, etc., and plastic is generally polyethylene, polyvinyl chloride, eva (standard name is Geomembrane) is a combination of impermeable geomembrane or composite geomembrane, because the composite white geotextile outside the protective effect, so the project is also called impermeable geotextile. Therefore, the two are essentially not much difference, but the argument is different. Waterproof board is also called geomembrane, customary to> 0.8mm thick geomembrane called waterproof board, & lt; 0.8mm called geomembrane, it is based on high molecular polymer as raw material made of impermeable material , Divided into homogeneous waterproof board and composite waterproof board

- Yes, geotextiles are generally resistant to acid degradation. They are designed to withstand various environmental conditions, including exposure to acids, making them suitable for applications where acid resistance is required.

- Please geotextile manufacturers offer,

- Please geotextile manufacturers offer,