Ceiling Light Cover Plate

Ceiling Light Cover Plate Related Searches

Best Inverter For Solar System Led Light For Chandelier Decorative Ceiling Plate For Light Fixture Inverter For 5kw Solar System Parts For Light Fixtures Transformer For Light Fixture Decorative Lights For Ceiling Lights For Kitchen Ceiling Ceiling Brackets For Lights Hanging Ceiling Chairs For BedroomsHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Plate For Sale Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Aluminum Bar Stock For SaleCeiling Light Cover Plate Supplier & Manufacturer from China

Okorder.com is a professional Ceiling Light Cover Plate supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Ceiling Light Cover Plate firm in China.Hot Products

FAQ

- I would like to finish my basement (pay to have it done) but to do it a little at a time for financial reasons. Would like dropped ceiling and wirng done first. Thanks!

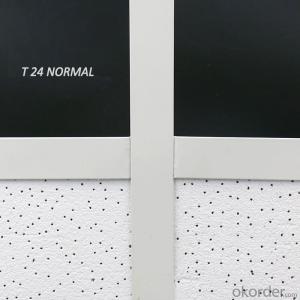

- Do the drop ceiling last. Why? A drop ceiling has a pc. of steel molding called *Wall mold*, that goes around the entire perimeter of the room. This is for the ceiling tile to rest on against the wall. Walls are finished first and then this molding is installed which gives a nice clean finished look around the edges of the room. If you put it up first, it will not look professional, and you drywall or other wall material will cover up the wall mold around the edge. Plus - You will undoubtedly have damage to the ceiling panels and or the grid work caused by hitting it with other materials as you or others are working on the walls. Do any wall framing first-just rough framing. Then do a ceiling plan layout on paper to scale so you can see where you want the lighting in the grid ceiling. Now, run wiring in walls and ceilings. Now hang drywall. Tape and finish drywall - cleanup. Now run grid ceiling metal framework and install lights in ceiling. Now prime and paint drywall as you now have lights installed. Now install ceiling tiles and baseboard. This is how I would have it done on a project.

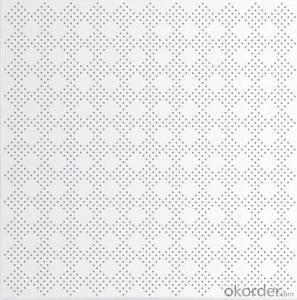

- Do the ceiling, the general use of what kind of specifications gypsum board and light steel keel?

- Ceiling more use 9.5mm, 12mm, 12.7mm thick gypsum board;

- I need to attach track lighting in an office with acoustical tiles. Can I screw the track directly into the metal tracks of the suspended ceiling? (running power is not a problem to the track, but the tiles have to stay)

- Check with your local building department. I expect you will find that your electrical code does not permit supporting fixtures from the T bar, tiles or the same support wires.

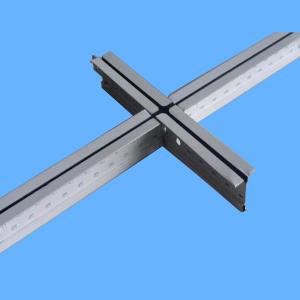

- Light steel keel ldu, cb, ldc, cs what it means

- Light steel keel according to the use of hanging keel and cut keel, according to cross-section of the form of V-type, C-type, T-type, L-keel. (1) product specifications series of keel main specifications are divided into Q50, Q75 and Q100. The main specifications of the ceiling keel are divided into D38, D45, D50 and D60. (2) Product marking method The marking order of light steel keel is: product name, code, width of section shape, height, thickness of steel plate and standard number. Such as cross-sectional shape of "C" type, width of 50mm, height of 15mm, steel plate thickness of 1. Smm of the ceiling keel marked as: building light steel keel DC 5 0 XIS XI. SGBllg sl (3) the appearance of quality light steel keel shape to be smooth, angular, cut not allowed to affect the use of burrs and deformation. Galvanized layer is not allowed to have skin, from the tumor, shedding and other defects. For corrosion, damage, dark spots, pitting and other defects, according to the provisions of the method should be tested in accordance with the provisions of Table 2-81. Appearance quality inspection, should be 0.5m away from the product under the conditions of bright light, the visual inspection. Light steel keel surface should be galvanized rust, the double-sided galvanized: excellent products not less than 120g / m * m, first-class goods is not less than 100g / m * m, qualified products not less than 80g / m *

- There is a ceiling of light steel keel partition to be how high, whether only need to do ceiling elevation, or to be higher than 20cm, or do the top plate bottom ~

- According to the normal process, it should be done first to do the ceiling wall.

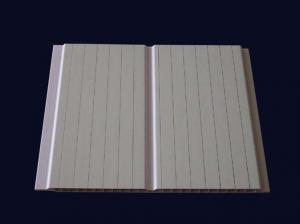

- Living room around the ceiling with light steel keel or wood keel?

- Of course, light steel keel, made out of norms, flat. Wood keel itself is not dry, do not believe you go to sell the wood where it touches itself is very wet, when the workers even when the workers can not dry all dry. So hanging the top of the late a lot of trouble. Not flat, deformation, corrosion, there are raw insects possible.

- I'm in the process of finishing my basement and only have the ceiling left to complete. I used metal studs for the framing and am using a metal grid system for a drop ceiling. How should I attach the wall molding to the walls? The manufacturer says to use nails, but that's obviously not an option with the metal studs. Would a drywall screw meant for metal framing work?

- The wall trim only holds the weight of 1/2 of the outermost tile. So, there is not much weight to support. I've successfully attached the wall tile to stucco'ed concrete walls using liquid nails adhesive. I used a couple nails and scrap boards leaning against the wall to hold the angle in place until the glue set. The t-strips are suspended from the ceiling. Since you have drywall, tack the angle in place with enough nails to hold it while the glue sets. Rather than liquid nails, I'd use something white (like RTV) so you don't have to repaint the glue that shows. Also, the RTV will fill in the gap where joint compound makes the wall not flat.

- Yes, I know I should get floor lamps since I have no overhead lights, but are there any non permanent ceiling hooks that would let you hang a light (as in weight) plug-in fixture?Also, what about from a tiled ceiling? Are there accessory stores for things that hang from the grid part?

- there are hooks with a double stick foam tape that will easily hold 10lbs. of weight. (Any hardware store) As long as what you are hanging is not too heavy, you should be fine. you can remove (when the time comes) with a razor blade and a little touchup paint.