Aluminum Grate Mesh

Aluminum Grate Mesh Related Searches

Led Light Bulbs For Ceiling Fixtures Led Lamps For Ceiling 42 In Ceiling Fan With Light Aluminum Coil Stock For Gutters Hole Saw For Aluminum Plate Aluminum Tread Plate For Trailer Bow Plate For Aluminum Boat Max Temp For Aluminum Foil Aluminum Foil For Key Fob Aluminum Foil For Hair FrizzHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Easy Deck Scaffold For Sale Ceiling Fan Lowest Price Stock Price For Aluminum Aluminum Coil Stock For Sale Aluminum Gutter Coil For Sale Used Aluminum Scaffolding For Sale 1/4 Aluminum Plate For Sale Aluminum Bar Stock For Sale Aluminum Round Stock For Sale Aluminum Diamond Plate For Sale Aluminum Scaffolding For Sale Craigslist 6061 Aluminum Plate For Sale Aluminum Dock Plate For Sale 7075 Aluminum Plate For Sale Aluminum Tread Plate For Sale Aluminum Checker Plate For Sale Aluminum Plate For Sale Near MeAluminum Grate Mesh Supplier & Manufacturer from China

Okorder.com is a professional Aluminum Grate Mesh supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Aluminum Grate Mesh firm in China.Hot Products

FAQ

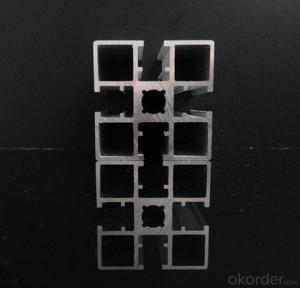

- The tolerance levels for aluminum profiles can vary depending on the specific requirements and applications. Generally, aluminum profiles have tight tolerance levels due to their importance in various industries such as automotive, aerospace, and construction. The most common tolerance levels for aluminum profiles include dimensional tolerances, straightness tolerances, and surface finish tolerances. Dimensional tolerances refer to the permissible deviation from the specified measurements of the profile. These tolerances ensure that the profile meets the required dimensions and can fit properly in the intended application. The dimensional tolerances for aluminum profiles are typically specified in terms of millimeters or inches. Straightness tolerances determine the allowable deviation from a perfectly straight line for the aluminum profile. This tolerance ensures that the profile is not bent or warped, which is crucial for maintaining structural integrity and accurate assembly. Surface finish tolerances define the acceptable level of imperfections on the surface of the aluminum profile. These imperfections can include scratches, indentations, or roughness. The surface finish tolerance is typically specified in terms of roughness average (Ra) or surface quality codes, such as anodized or powder-coated finishes. It is important to note that the specific tolerance levels for aluminum profiles can vary depending on the manufacturing process, the intended application, and the industry standards. Therefore, it is essential to consult the relevant specifications, industry standards, or the supplier's guidelines to determine the precise tolerance levels for a specific aluminum profile.

- Yes, aluminum profiles can be used for creating lighting fixtures. Aluminum is a versatile material that is lightweight, durable, and has excellent thermal conductivity, making it suitable for dissipating heat generated by lighting components. Additionally, aluminum profiles can be easily shaped, allowing for various designs and forms of lighting fixtures.

- Yes, aluminum profiles can be a viable alternative to steel or iron in many applications. Aluminum profiles are lightweight, durable, and have excellent corrosion resistance, making them suitable for various industries such as construction, automotive, aerospace, and electrical. Unlike steel or iron, aluminum has a high strength-to-weight ratio, meaning it can provide the same strength while being significantly lighter. This makes aluminum profiles easier to handle, transport, and install, reducing overall costs. Additionally, aluminum profiles can be easily extruded into complex shapes, allowing for design flexibility and customization. However, it is important to note that aluminum profiles may not be suitable for all applications that require the high strength or hardness provided by steel or iron. Therefore, the choice between aluminum, steel, or iron profiles will depend on the specific requirements of the project or product.

- Aluminum surface treatment products we have color (pure black and beige wood etc.), the surface coating by scratching the surface, color and color difference of aluminum (aluminum color, the background is simple) after repair or there will be a difference at present, technical staff provides a profile of color, it can paint pen profile the scratch (paint pen according to the material surface spray paint, please fill out this factory can scratch the gap! It's really hard to findConsult an expert who specializes in aluminum processing. What's the effective remedy for scratching after spraying? Are there any professional manufacturers of this kind of paint pen?

- Please fill out paint pen manufacturers can scratch the gap, is the best way, the color of the paint can't find the same, have a great relationship with the concentration ratio, so, when buying sheet with requirements of factory repair paint pen!

- Green building projects can utilize aluminum profiles effectively. Aluminum, being an eco-friendly material, offers numerous advantages in the realm of green building. To begin with, aluminum's lightweight nature cuts down on transportation costs and energy consumption during construction. Furthermore, aluminum is entirely recyclable, ensuring that it can be reused indefinitely without any loss in quality. This characteristic makes aluminum an ideal option for green building projects as it aids in waste reduction and promotes a circular economy. Additionally, aluminum boasts a lengthy lifespan and necessitates minimal upkeep, further enhancing its sustainability. It is worth noting that aluminum profiles can easily be integrated with other green building materials like glass, enabling energy-efficient designs that maximize natural light and minimize the reliance on artificial lighting. In conclusion, aluminum profiles offer a sustainable and versatile choice for green building projects.

- Aluminum profiles play a significant role in enhancing the energy efficiency of lighting systems. Firstly, aluminum is a lightweight and highly conductive material, allowing for efficient heat dissipation. This is crucial in lighting systems as excessive heat can reduce the lifespan and efficiency of the bulbs. By using aluminum profiles, the heat generated by the light source can be effectively transferred away, ensuring optimal performance and longevity. Furthermore, aluminum profiles are versatile and can be designed to accommodate various lighting components such as LED strips or bulbs, reflectors, and lenses. These profiles provide a stable and secure housing for these components, preventing any damage or misalignment that could impact the efficiency of the lighting system. Additionally, aluminum profiles often feature precision engineering, allowing for easy installation and maintenance, further contributing to the overall energy efficiency of the system. Another key advantage of aluminum profiles is their ability to act as a heat sink. By directing heat away from the light source, the profiles help to maintain lower operating temperatures, reducing energy consumption and increasing the efficiency of the lighting system. This is particularly important for LED lighting, as they are highly sensitive to heat and can experience significant light output degradation if not properly cooled. Aluminum profiles enable efficient thermal management, ensuring that the LED lights operate at their optimum level, saving energy and reducing the need for frequent replacements. Moreover, aluminum is a recyclable material, making it an environmentally friendly choice for lighting systems. Using aluminum profiles promotes sustainable practices by reducing the demand for raw materials and minimizing waste. This aligns with the principles of energy efficiency and conservation, as it reduces the overall carbon footprint of the lighting system. In summary, aluminum profiles contribute to energy-efficient lighting systems by facilitating effective heat dissipation, providing a stable housing for lighting components, acting as a heat sink, and promoting sustainable practices. These profiles enhance the performance, lifespan, and energy efficiency of lighting systems, making them an essential component in modern lighting solutions.

- Aluminum Alloy rail safety glass balcony design, Aluminum Alloy profiles for what is standard specifications?

- Aluminum alloy profiles are basically no GB non-standard, but the state has special specifications for architectural aluminum profiles, mainly to the thickness of the profiles, materials and so on.Each aluminum alloy profiles manufacturing enterprises are basically similar products, but in specific structure of the discrepancy. But such as the more general series, such as GB 50, 868, and 90, these are basically the same.The 80 series and the 60 series refer to the aluminium alloy profiles with widths of 80 mm and 60 mm.According to the extrusion process, it can be divided into oxidation, electrophoresis, electrostatic powder spraying, fluorocarbon spraying, which means different coating methods. At present, 85% of the consumption in the market is electrostatic powder spraying section, that is colored aluminum section.I have been involved in related work for several years. If you need any help, please contact me.

- What kinds of profiles are made of aluminium alloy windows?

- Four, look at the materialMaterial in the material, there are 6 main areas of reference:The thickness: Aluminum Alloy sliding window of 70 series, 90 series two, Aluminum Alloy housing interior sliding doors with 70 series. The number of aluminum alloys indicates the number of millimeters of the thickness of the door frame. Common aluminum alloy sliding window has 55 series, 60 series, 70 series, 90 series of four kinds. Selection should be based on the window size and the local wind pressure value is determined as shall be not less than 70 series Aluminum Alloy closed balcony sliding window.The strength: tensile strength should be 157 per square millimeter of Newton, yield strength to reach 108 per square millimeter of Newton. When buying, you can moderate bending profiles, and then you should be able to restore the original state.3: the same color Aluminum Alloy profile color should be consistent, such as color, that is not to buy.The flatness: check the Aluminum Alloy profile surface, should not sag or bulge.The gloss: avoid buying Aluminum Alloy doors and windows opening on the surface of the bubble (white) and ash (black), crack, burr, profile leather and other obvious defects.The oxidation degree of oxide film thickness should reach 10 micron. When choosing, light the surface of the profile to see if the oxide film on the surface can be removed.