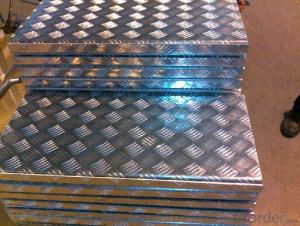

6061 Aluminum Tread Plate

6061 Aluminum Tread Plate Related Searches

Led Light Bulbs For Ceiling Fixtures Led Lamps For Ceiling 42 In Ceiling Fan With Light Aluminum Coil Stock For Gutters Aluminum Foil For The Grill Hole Saw For Aluminum Plate Aluminum Tread Plate For Trailer Bow Plate For Aluminum Boat Aluminum Foil For Grow Room Aluminum Foil For Joint PainHot Searches

Stock Price For Aluminum Aluminum Coil Stock For Sale Aluminum Gutter Coil For Sale Used Aluminum Scaffolding For Sale 1/4 Aluminum Plate For Sale Aluminum Bar Stock For Sale Aluminum Round Stock For Sale Aluminum Diamond Plate For Sale Aluminum Scaffolding For Sale Craigslist 6061 Aluminum Plate For Sale Aluminum Dock Plate For Sale 7075 Aluminum Plate For Sale Aluminum Tread Plate For Sale Aluminum Checker Plate For Sale Aluminum Plate For Sale Near Me Plate Aluminum For Sale Aluminum Plate For Sale Aluminum Square Stock For Sale Aluminum Flat Stock For Sale Billet Aluminum Stock For Sale6061 Aluminum Tread Plate Supplier & Manufacturer from China

Okorder.com is a professional 6061 Aluminum Tread Plate supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 6061 Aluminum Tread Plate firm in China.Hot Products

FAQ

- Can someone explain the movement of electrons in a pure block of aluminum metal? At they free to move around between similar energy levels? Are they bound to Al atoms? What about orbital overlap?

- Any element that allows the transfer of electrical flow to move across it usually has the characteristic of having free movement electrons in the outer shell. This is why metals are particularly good at electrical conduction. The best metal for transferring electrical charge is silver followed by copper and then aluminum. Much electrical wire is made from pure aluminum because it is cheaper than copper or silver and the resistance to flow is only slightly lower than copper. The electrons in the outer shells are still bound to the aluminum nucleus but they are free to accept a charge from neighboring aluminum atoms and transfer that charge to the next aluminum in the electrical flow. This is basically the definition of electrical resistance. Copper performs this transfer more efficiently than aluminum so it's electrical resistivity is less than aluminums. But in both base metals, the outer electrons never leave the atom, they simply transfer their charge to the next atom in line

- Hi guys. I was just wondering if you can give me some tips or information on what you know about painting on metal. The metal that is of concern is aluminium and I would like to put a stencil over this aluminium and just blast it with a can of krylon. Of course...this aluminium piece is actually part of the housing for my cell phone so doing it like this would probably not be right and the paint would probably wear out. I am mainly interested in finding out what kind of paint to use, what tools i need, and how to achieve an extremely! durable! matte finish because this phone is thrown around and going in and out of my pocket the paint will have to withstand getting rubbed down everyday by my pockets.That was a very long question, thanks for bearing with me and thanks in advance for those who provided me with an answer/thought. THANKS!

- This Site Might Help You. RE: Spray Paint Aluminium Durable. Matte. Finish? Hi guys. I was just wondering if you can give me some tips or information on what you know about painting on metal. The metal that is of concern is aluminium and I would like to put a stencil over this aluminium and just blast it with a can of krylon. Of course...this aluminium piece is actually...

- Aluminum sheets are typically made of pure aluminum or aluminum alloy, which is a combination of aluminum and other elements such as copper, magnesium, or zinc. The exact composition of the alloy depends on the specific application and desired properties of the sheet. Pure aluminum sheets are softer and more malleable, while alloyed aluminum sheets offer increased strength, durability, and resistance to corrosion. The sheets are produced through a process called rolling, where a large block or ingot of aluminum is passed through a series of rollers to reduce its thickness and create the desired sheet size.

- Aluminum sheets possess exceptional thermal conductivity characteristics. With a thermal conductivity of approximately 237 Watts per meter-Kelvin (W/mK), aluminum surpasses other commonly used metals like steel or copper in this aspect. Consequently, aluminum sheets excel in the efficient transfer of heat over their surface. Due to its high thermal conductivity, aluminum can swiftly conduct and distribute heat, making it an optimal choice for applications that demand efficient heat transfer, including heat exchangers, cooling systems, and heat sinks. Moreover, aluminum's lightweight nature and resistance to corrosion further enhance its popularity in thermal management applications. In summary, aluminum sheets exhibit outstanding thermal conductivity properties, positioning them as the preferred material in industries that prioritize efficient heat transfer.

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for various industrial applications, including shelving. It offers strength and stability while being easy to clean and maintain. Additionally, aluminum's versatility allows for customization and modification to fit specific storage needs.

- Indeed, aluminum sheets prove to be a fitting choice when it comes to lightweight structures. Renowned for its low density and impressive strength-to-weight ratio, aluminum emerges as an optimal material for applications requiring reduced weight. Industries such as aerospace, automotive, and construction frequently rely on aluminum sheets due to their exceptional corrosion resistance, durability, and malleability. These properties facilitate effortless fabrication and installation. Moreover, the versatility of aluminum sheets extends to their effortless joining through diverse welding and adhesive methods, thereby bolstering their aptness for lightweight structures.

- Yes, aluminum sheets can be used for electrical connectors. Aluminum is a highly conductive material and has excellent electrical conductivity. It is commonly used in various electrical applications, including connectors. Aluminum connectors are lightweight, durable, and cost-effective compared to other materials such as copper. However, it is important to consider certain factors such as the type and size of the connection, the amount of current to be carried, and the environment in which the connectors will be used. Additionally, proper insulation and protection measures should be taken to prevent corrosion, as aluminum can be susceptible to oxidation. Overall, aluminum sheets can be a suitable choice for electrical connectors, but careful consideration of specific requirements and conditions is necessary.