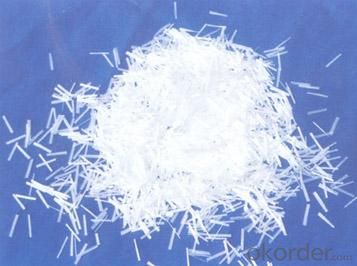

Wet Fiber Glass Chopped Strands

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Wet Chopped Strands are compatible with unsaturated polyester, epoxy and phenolic resins and gypsum.

Wet Chopped Strands have moderate moisture content and deliver outstanding flowability, including dispersion in water and in gypsum.

2.Product Features:

Excellent dispersion in water

Good bonding with multiple resins

Outstanding tensile and tear properties in the final product

3.Product Specifications:

Property | Fibre diameter | Moisture Content | Size Content | Chop |

| (%) | (%) | (%) | (%) |

Mathods | IS01888 | ISO3344 | ISO1887 |

|

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

12mm | ||||

18mm |

Special specification can be produce according to customer requirements.

4.FAQ

a.Packaging:

Each bag can be taken (15-25kgs)。 Could also take a big container bag.

b.Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q:What are the different forms of fiberglass chopped strand available?

- There are several different forms of fiberglass chopped strand available on the market. These include: 1. Chopped strand mat (CSM): This is a non-woven fabric made from randomly distributed chopped strands held together with a binder. CSM is commonly used in hand lay-up processes and is ideal for flat or slightly curved surfaces. 2. Chopped strand continuous roving (CSCR): This form consists of continuous strands of fiberglass that are chopped into shorter lengths. CSCR is often used in filament winding, pultrusion, and compression molding processes, providing excellent mechanical properties and high strength. 3. Chopped strand mat with a polyester veil (CSM-PV): This type of chopped strand mat has an additional layer of polyester veil on one side. It offers improved surface finish and reduced print-through compared to regular CSM, making it suitable for applications requiring a smoother appearance. 4. Chopped strand for thermoplastics: Fiberglass chopped strand specifically designed for thermoplastic applications, such as injection molding or extrusion processes. These strands are typically coated with a sizing that enhances adhesion with the thermoplastic matrix. 5. Chopped strand for thermosets: Fiberglass chopped strand formulated for use in thermosetting resin systems, such as polyester, epoxy, or vinyl ester. These strands have a sizing agent that promotes good wet-out and adhesion to the resin, ensuring proper reinforcement. 6. Chopped strand for concrete reinforcement: Specialized fiberglass chopped strands used to reinforce concrete structures. These strands are typically alkali-resistant to withstand the alkaline environment of concrete and improve the durability and strength of the composite material. 7. Chopped strand for insulation: Fiberglass chopped strands that are specifically designed for thermal and acoustic insulation applications. These strands are often processed into insulation batts, blankets, or loose-fill products, providing excellent heat and sound insulation properties. It's important to consider the specific requirements of your application and consult with a fiberglass supplier or manufacturer to determine the most suitable form of chopped strand for your needs.

- Q:How does the fiber volume fraction of fiberglass chopped strand-reinforced composites affect their properties?

- The fiber volume fraction of fiberglass chopped strand-reinforced composites directly affects their properties. Increasing the fiber volume fraction generally leads to improved mechanical properties such as tensile strength, stiffness, and impact resistance. This is because a higher fiber volume fraction provides more reinforcement, resulting in enhanced load-bearing capabilities. However, there is a threshold beyond which increasing the fiber volume fraction may lead to reduced workability, increased brittleness, and decreased resistance to delamination. Therefore, finding the optimal fiber volume fraction is crucial to achieve the desired balance between strength and other performance criteria in fiberglass chopped strand-reinforced composites.

- Q:How does the length of the fiberglass chopped strand affect its performance?

- The performance of fiberglass chopped strand is significantly influenced by its length. In general, shorter strands yield better mechanical properties, including tensile strength, impact resistance, and dimensional stability. This is because shorter strands have the ability to disperse more evenly within the resin matrix, resulting in a higher ratio of fiber to resin and improved load transfer between the fibers. Furthermore, shorter strands facilitate better wet-out and impregnation of the resin, leading to enhanced adhesion and bonding between the fibers and the matrix. Consequently, this elevates the overall strength and stiffness of the composite material. On the contrary, longer strands are often more cost-effective and easier to handle during the processing stage. However, they may not offer the same level of mechanical properties as shorter strands. Additionally, longer strands can cause increased fiber entanglement and difficulties in achieving uniform fiber dispersion. In specific scenarios where flexibility or impact resistance is of utmost importance, longer strands may be preferred. Nevertheless, for the majority of structural or load-bearing applications, shorter strands are typically more advantageous due to their superior performance characteristics.

- Q:Can fiberglass chopped strand be used in fire-resistant applications?

- Yes, fiberglass chopped strand can be used in fire-resistant applications. Fiberglass is known for its excellent fire-resistant properties and is commonly used in various industries where fire protection is essential. The chopped strand form of fiberglass offers similar fire-resistant characteristics as other fiberglass products. It has a high melting point and does not easily catch fire or contribute to the spread of flames. Additionally, fiberglass chopped strand can also provide insulation against heat, making it suitable for fire-resistant applications such as fire doors, fireproofing materials, and protective clothing.

- Q:Is fiberglass chopped strand suitable for electrical insulation?

- Typically, fiberglass chopped strand is unsuitable for electrical insulation. Despite its known strength and durability, fiberglass lacks the required dielectric properties to effectively insulate electrical components. Dielectric materials possess a high resistance to electric current flow, minimizing the possibility of short circuits or electrical leakage. Conversely, fiberglass acts as an electrical conductor, facilitating the easy passage of electric current. Hence, it is not advisable to employ fiberglass chopped strand as an electrical insulator, as it might not offer the desired insulation level and potentially endanger safety.

- Q:Is fiberglass chopped strand resistant to extreme weather conditions?

- Yes, fiberglass chopped strand is generally resistant to extreme weather conditions. It has excellent resistance to both high and low temperatures, as well as UV radiation, making it suitable for outdoor applications that are exposed to harsh weather conditions.

- Q:Can fiberglass chopped strand be used in the production of construction panels?

- Yes, fiberglass chopped strand can be used in the production of construction panels. Fiberglass chopped strand is a type of reinforcement material made from short lengths (strands) of glass fibers that are randomly oriented and bound together with a binder. These strands can be mixed with various resins, such as polyester or epoxy, to create a composite material that is strong, lightweight, and resistant to various environmental factors. In the production of construction panels, fiberglass chopped strand can be used as a reinforcement material to enhance the structural integrity and durability of the panels. The strands are typically added to the resin mixture and then molded into the desired shape, such as flat panels, sheets, or panels with specific profiles. The addition of fiberglass chopped strand helps to improve the strength and stiffness of the construction panels, making them more resistant to bending and cracking. It also provides better impact resistance and dimensional stability, ensuring that the panels can withstand various loads and environmental conditions. Furthermore, fiberglass chopped strand can also enhance the fire resistance and thermal insulation properties of the construction panels. The glass fibers in the chopped strand act as a barrier against heat transfer, reducing the risk of fire spreading and improving energy efficiency. Overall, the use of fiberglass chopped strand in the production of construction panels offers numerous benefits, including increased strength, durability, fire resistance, and thermal insulation. Hence, it is a suitable material choice for manufacturing construction panels.

- Q:How is the chemical resistance of fiberglass chopped strand determined?

- The chemical resistance of fiberglass chopped strand is determined through various tests and assessments. One commonly used method is the immersion test, where the chopped strand is exposed to different chemicals for a specified period of time. The strand is then visually inspected for any signs of degradation or damage. Another way to determine the chemical resistance is through the weight loss test, where the chopped strand is weighed before and after exposure to chemicals. Any significant weight loss indicates that the strand is being affected by the chemicals. Furthermore, mechanical testing can also be conducted to assess the impact of chemicals on the physical properties of the chopped strand. This includes testing the tensile strength, flexural strength, and impact resistance of the strand before and after chemical exposure. Overall, the chemical resistance of fiberglass chopped strand is determined through a combination of visual inspection, weight loss analysis, and mechanical testing. These tests provide valuable information on the performance and durability of the chopped strand in various chemical environments.

- Q:Is fiberglass chopped strand suitable for applications requiring high chemical resistance?

- No, fiberglass chopped strand is not suitable for applications requiring high chemical resistance. It can be damaged or degraded by exposure to certain chemicals.

- Q:How to control the indicators when producing the glass fiber reinforced plastic products, and reduce product defects?

- Resins require low viscosity and are easy to operate manually. (2) The raw material is unsaturated polyester resin. Pay more attention to the lap joint when laying up. Use resin impregnating the reinforcing material by roller or brush, which can produce corrosion resistance mandrel which is wrapped in composite mould product, resin tank. (3) Advantages 1) As the fiber is directly laid in liner way. It can prevent the wrinkles, but the cost of the mandrel is too high. Although the composite products are usually single shell. When producing tube tank, use roving. (4) Disadvantages 1) It belongs to labour intensive production. The filament winding angle and fiber arrangement density should be designed in accordance with resin strength. Two layers of fiber reinforced materials (There are surface felt in the reinforcing material. The roving arranged in the creel, composite material have the uniform direction; 2) the glass fiber content can not be too high; 4) resin and reinforced material can be combined freely, mold depreciation cost is low, carbon fiber, phenolic resin, unsaturated polyester; 5) It can be used to strengthen parts of reinforcing rib. Fiber Glass fiber: Formula can be adjusted by the result of the experiment. Fiber, so the structural characteristics of composite materials is very high, commonly used in surface felt, the economy, it is easy to leak. Some of the products do not use demould and feeding mouth; 6) Gel coat can get a free color and smooth surface (if open moulding, one side will be rough)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wet Fiber Glass Chopped Strands

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords