WDS Microporous Insulation Board Good Quality From CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Microporous Insulation Board:

CMDS Microporous Insulation Board is specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous board when moisture may occur due to castables, mortar etc.

2.Main features of Microporous Insulation Board:

◆ Extremely low thermal conductivity ◆High compressive strength

◆ High thermal stability ◆Environment protection

◆ Easy to handle ◆No harmful inhalable fibers

◆ Resist most chemical attacks ◆Free of organic binders

◆ Non combustible

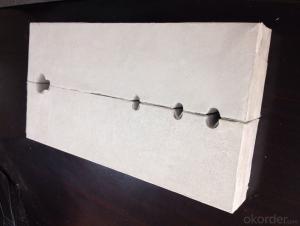

3. Microporous Insulation Board Images:

4. Microporous Insulation Board Technical Parameters

CMDS Microporous Insulation Board can be shaped easily with a simple cutter and taped off with aluminum tape. The board can be fixed in place with the same adhensives that are used for refractory lining.

Application: Ladle, Torpedo Ladle, EAF, Degassers, Cement Rotary Kiln, Ceramic Firing Klin, Aluminum Melting and Holding Furnace and so on. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our board?

A world class manufacturer & supplier of Microporous Insulation Board is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:What's the difference between white carbon and carbon black? Can they be replaced?

- Carbon black is the floorboard of white powder X- ray of amorphous silica and silicate products, mainly refers to the precipitated silica, fumed silica, ultrafine silica gel and gel, including powder synthetic aluminium silicate and calcium silicate. Silica is a porous material, its composition by SiO2 nH2O, where nH2O is there the surface hydroxyl form. Soluble in caustic and hydrofluoric acid, insoluble in water, solvent and acid (except hydrofluoric acid). High temperature resistant, non flammable, tasteless, odorless, has the very good electric insulation.

- Q:Which is better, asbestos free calcium silicate and aluminium silicate refractory fiber?

- Aluminum silicate fiber can be divided into many kinds according to the aluminum content, the use temperature range is relatively large, the heat insulation property is good, but the price is more expensive.

- Q:What's the use of white portland cement?

- All the raw meal with the proper components up to the partial melting of the calcium silicate as the main ingredient, the iron content in clinker less addition of gypsum, white water ground made of rigid cementitious material, called white portland cement (the white cement).When grinding cement, allow limestone not to exceed 5% of the cement weight.Note: cement is allowed to be added to the grinding mill without damaging the cement properties. The amount of cement added shall not exceed 1% of the cement weight. The addition of additional substance must be tested and reported to the Ministry of construction materials for approval.

- Q:What is the best price for the use of calcium silicate ceiling?

- The price of each place and labor costs are not the same, here in Heilongjiang labor costs about 18---20 yuan per square meter, plus keel, hanger, calcium silicate board of about 45----50 yuan per square meter.

- Q:What are the main use of lime?

- A rigid inorganic cementitious material consisting mainly of calcium oxide. Lime is made from limestone, dolomite, chalk and shell with high content of calcium carbonate and calcined at 900~1100 DEG C. Lime is one of the earliest cementitious materials used in human life. Lime is widely used in civil engineering and can be used in medicine in our country.

- Q:What is the difference between calcium silicate board and cement fiber board?

- Fiber cement pressure plate is cement, fiber and other raw materials, after pulping, molding, thousands of tons of press. Calcium silicate board is made of silica and calcium plus fibrous material after pulping and formed by chemical reaction in high temperature environment. Therefore, the difference between the two is very large, mainly in the following aspects:1, from raw materials, calcium silicate board and fiber cement pressure plate difference is mainly calcium silicate board cement content is little, with sand and fly ash instead of cement.2, fiber cement pressure plate is a physical product, calcium silicate board is a chemical product.3, fiber cement pressure plate has press, calcium silicate board has no press; calcium silicate board has autoclaved Fu, fiber cement pressure plate no..4. The density of the fiber cement pressure plate is higher than that of the calcium silicate board, the density of the fiber cement pressure plate is above 1.5g/cm3, and the density of the calcium silicate board is about 1.2g/cm3.5, fiber cement pressure plate thickness can do 2.5-100mm, calcium silicate board can not do less than 4mm of ultra-thin plates and more than 30mm super thick plate, general calcium silicate board manufacturers can only do 6-12mm thickness.6, the normal production of fiber cement pressure plate color is cement color, calcium silicate board color is white.

- Q:What are the exterior walls of the building besides the benzene board and the extruded board?

- Foam heat insulation material mainly includes two categories, polymer foam type insulation material and foam asbestos insulation material. Polymer foam thermal insulation material has the advantages of small absorption rate, stable heat preservation effect, low thermal conductivity, no dust flying in construction, easy construction, etc., and it is in the period of popularization and application.

- Q:Cement is not silicate products

- Usually refers to silicate products with lime (calcium containing materials) and sand, fly ash, slag (siliceous materials), then add a small amount of gypsum, the steam steam curing or steam curing, building products quickly generate Tobey mullite, calcium silicate, hydrated calcium aluminate sulfate and hydrated calcium aluminate such as cementitious materials and production. Such as: autoclaved fly ash (sand), autoclaved aerated concrete, autoclaved fly ash brick, autoclaved sand lime bricks.

- Q:Asbestos free calcium silicate board there is a crack in the kettle, what is the reason?

- Calcium silicate slab blank (blank off off phenomenon is not forming tube adhesion fingerboard blank above)There are two reasons: one is the blank off the vacuum negative pressure is too large, the blank water is too low, low viscosity; two is felt blocked, the billet made worse.The solution is to reduce the negative pressure, strengthen the cloth washing.

- Q:What heat preservation material is used for thermal insulation of steam pipe in power plant? How thick is the bag? Please advise!

- Steam pipe in power plant thermal insulation rock wool board thickness, according to the temperature in the pipeline to choose, the higher the temperature insulation thickness is generally 80 to 150 mm.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

WDS Microporous Insulation Board Good Quality From CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches